CHT 001 - Manifold microchannel heat sink

Modern electronics, especially high-performance computing systems and power electronics, generate significant amounts of heat. Effective cooling is crucial to prevent overheating, ensure reliable operation, and extend the lifespan of these devices. Microchannel heat sinks have emerged as a highly efficient cooling solution, utilizing a network of tiny channels to facilitate heat transfer from the heat source to a cooling fluid. These compact and effective heat sinks are found in a wide range of applications, from data centers and electric vehicles to medical devices and aerospace systems.

Conjugate Heat Transfer (CHT) simulation plays a vital role in understanding and optimizing the performance of microchannel heat sinks. It allows engineers to accurately model the complex interplay of heat transfer mechanisms within these systems, including:

- Conduction: Heat transfer through the solid components of the heat sink, such as the base and fins.

- Convection: Heat transfer between the solid surfaces and the flowing coolant.

- Fluid Flow: The movement of the coolant through the microchannels, influencing heat transfer rates and pressure drop.

By considering all these factors simultaneously, CHT simulation provides valuable insights into:

- Temperature Distribution: Identifying hotspots and potential areas of thermal stress.

- Flow Characteristics: Optimizing channel geometry and flow rates for efficient heat removal.

- Cooling Performance: Evaluating the overall effectiveness of the heat sink design.

CHT simulation empowers engineers to refine microchannel heat sink designs for optimal thermal management, leading to improved performance, reliability, and longevity of electronic devices. It allows for virtual prototyping and optimization, reducing the reliance on costly and time-consuming physical experiments. Further, Quanscient Allsolve makes it simple and cost-effective to simulate CHT in your 3D designs.

Demo project: CHT in a Microchannel

Simulation setup guide

Section titled “Simulation setup guide”Here you’ll find a simplified, example case level guide for setting up a conjugate heat transfer simulation in a microchannel heat sink.

Step 1 - Define variables

Section titled “Step 1 - Define variables”-

Start out in the

Commonsidebar by defining variables for model dimensions:Name Description Expression l1 length 1 [m] 0.6e-3l2 length 2 [m] 0.5e-3l3 length 3 [m] 0.3e-3l4 length 4 [m] 0.15e-3m1 Number of mesh segments along l1 12m2 Number of mesh segments along l2 10m3 Number of mesh segments along l3 12m4 Number of mesh segments along l4 5 -

Define variables for other key values:

Name Description Expression VolumeFlowRate Volume flow rate [mL/s] 0.0001UniformHeatFlux Uniform heat flux [W/m^2] 220000InletArea Area of inlet [m^2] l3 * l3InletVel Inlet velocity magnitude [m/s] VolumeFlowRate * 1e-6 / InletAreaInletTemp Inlet temperature [K] 293Ahsbase Base area for thermal resistance calculation [m^2] 10.02 * 11.4 * 1e-6 -

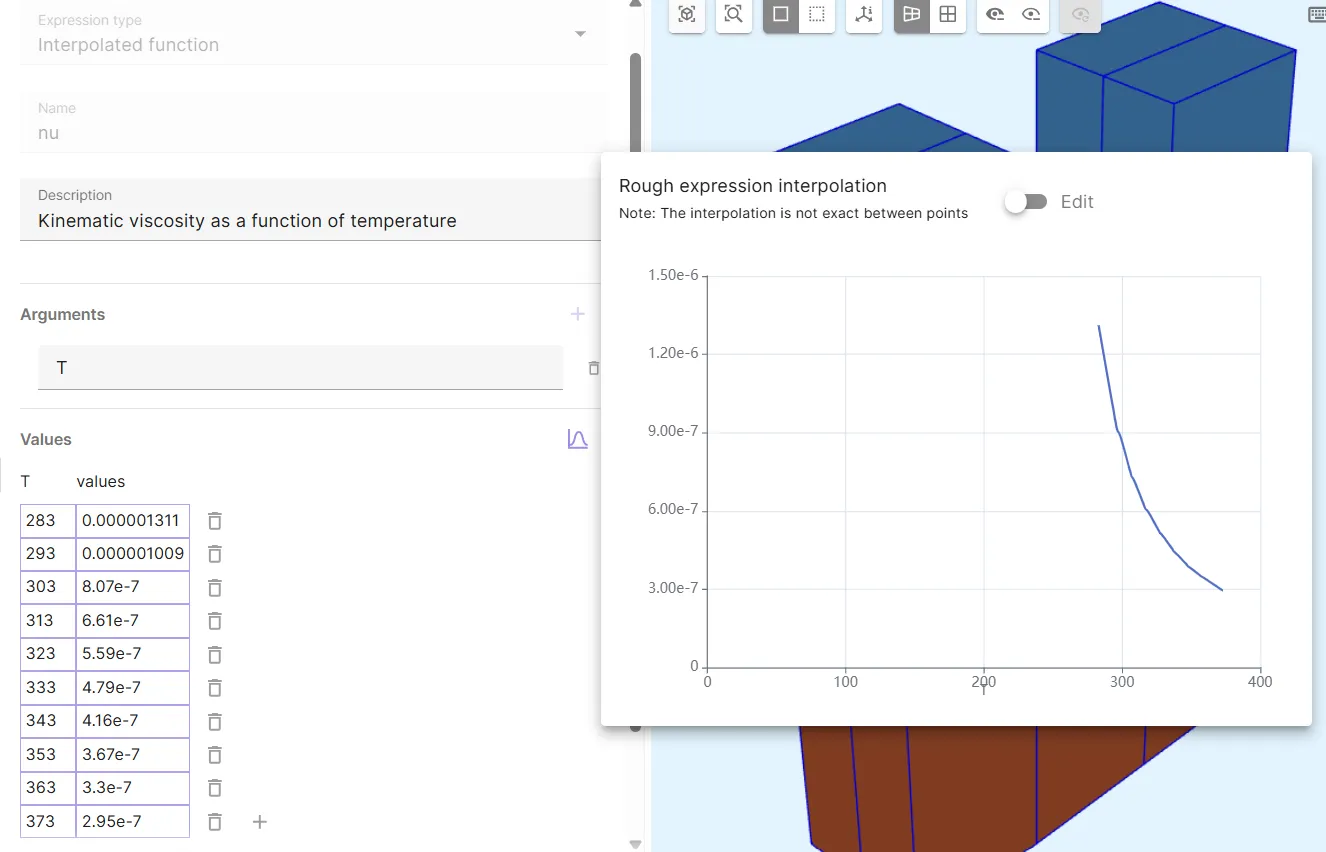

Define the interpolated function

nu:Name Description Arguments nu Kinematic viscosity as a function of temperature TImport file viscosity.csv, containing the following 10 rows of input-value pairs for

nu:T values 2830.0000013112930.0000010093038.07e-73136.61e-73235.59e-73334.79e-73434.16e-73533.67e-73633.3e-73732.95e-7

Finalized nu:

Step 2 - Build the geometry

Section titled “Step 2 - Build the geometry”-

In the

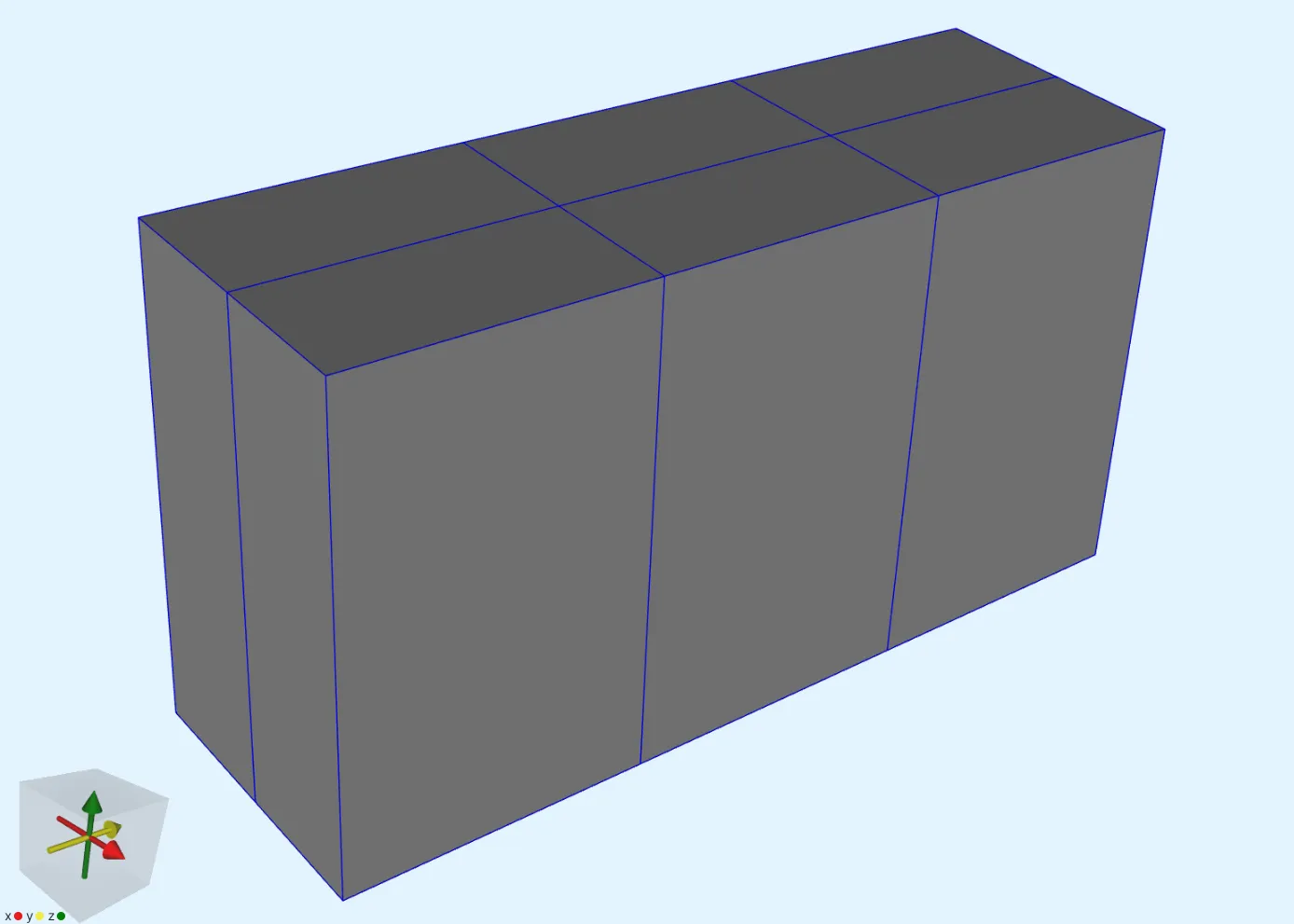

Modelsection, create the model geometry by building Box elements and using the Translation operation:Name Element type Center point [m] Size [m] Rotation [deg] box Box X: 0X: l4X: 0Y: -l3Y: l3Y: 0Z: l2 / 2Z: l2Z: 0Name Element type Target volumes Translation [m] Copy Repeat count translate Translation box ( 1)X: 0☑️ 2Y: l3Z: 0Name Element type Target volumes Translation [m] Copy Repeat count translate 2 Translation all three boxes ( 1 - 3)X: -l4☑️ 1Y: 0Z: 0

-

Continue adding elements:

Name Element type Center point [m] Size [m] Rotation [deg] box 2 Box X: 0X: l4X: 0Y: -l3Y: l3Y: 0Z: l1 / 2 + l2Z: l1Z: 0Name Element type Target volumes Translation [m] Copy Repeat count translate 3 Translation box 2 ( 109)X: 0☑️ 2Y: l3Z: 0Name Element type Target volumes Translation [m] Copy Repeat count translate 4 Translation three second level boxes ( 109 - 111)X: -l4☑️ 1Y: 0Z: 0

-

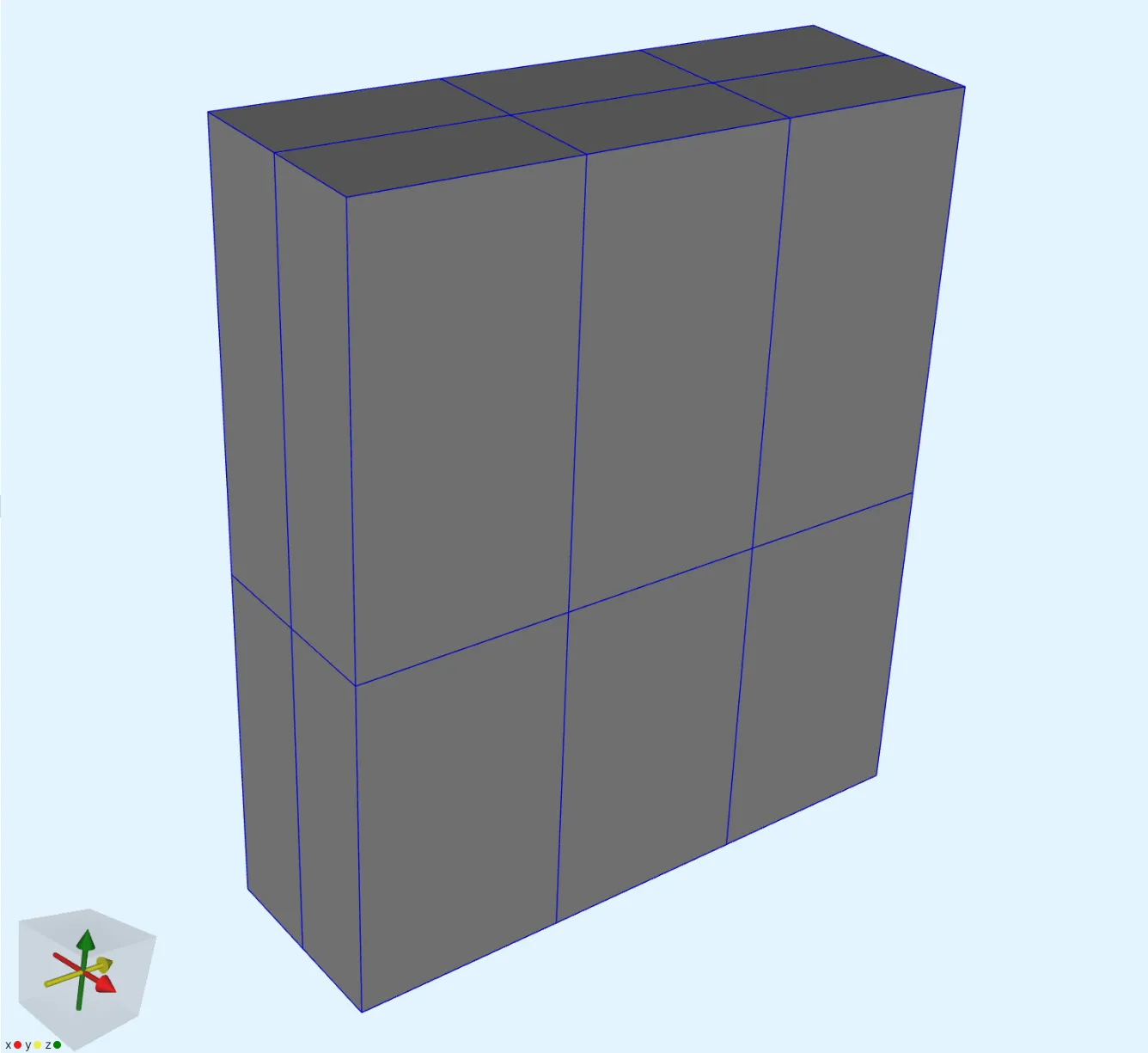

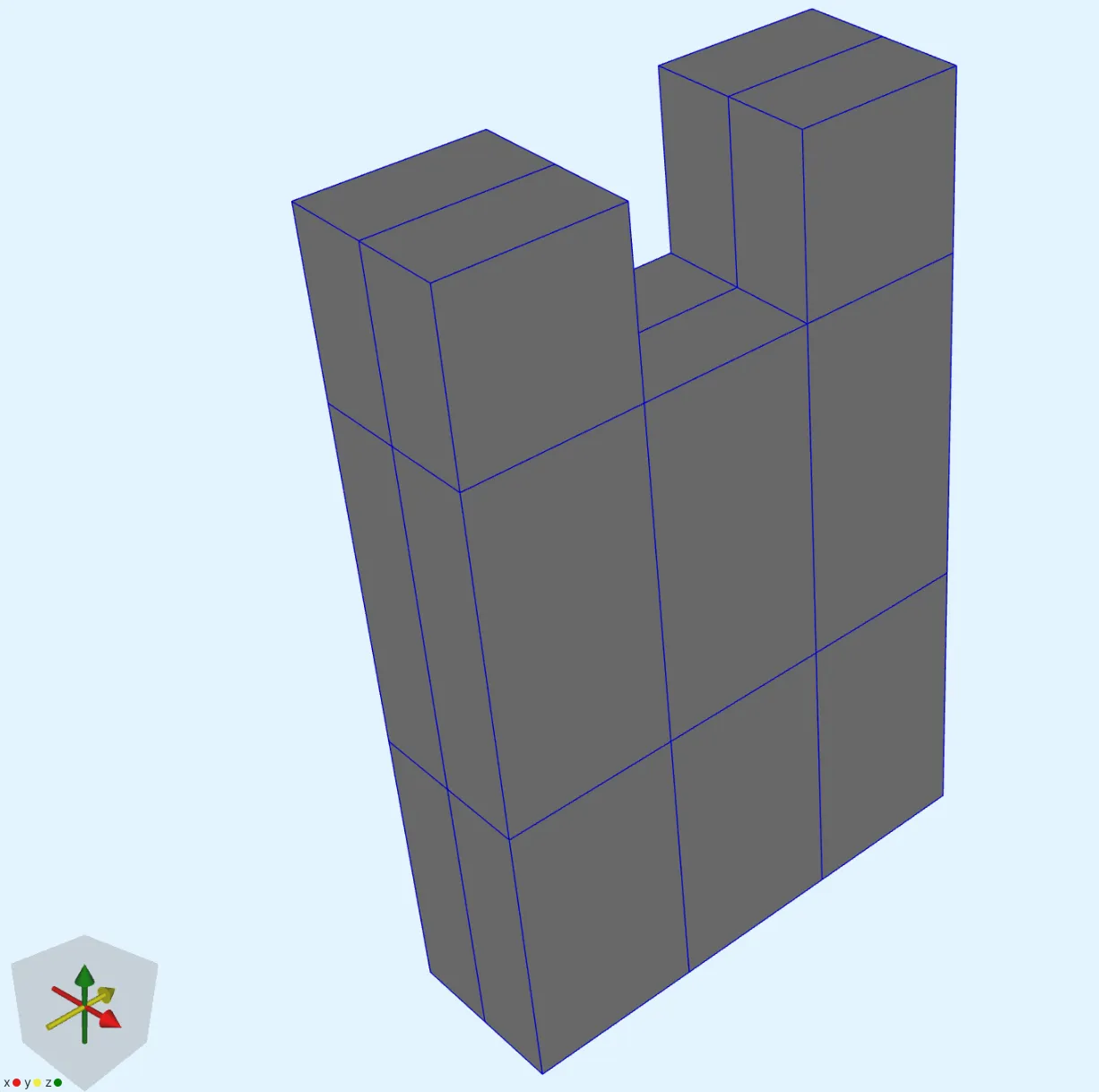

Add the remaining elements:

Name Element type Center point [m] Size [m] Rotation [deg] box 3 Box X: 0X: l4X: 0Y: -l3Y: l3Y: 0Z: l3 / 2 + l2 + l1Z: l3Z: 0Name Element type Target volumes Translation [m] Copy Repeat count translate 5 Translation box 3 ( 217)X: -l4☑️ 1Y: 0Z: 0Name Element type Target volumes Translation [m] Copy Repeat count translate 6 Translation two 3rd level boxes ( 217, 218)X: 0☑️ 1Y: 2 * l3Z: 0

Finished geometry:

Step 3 - Define the materials

Section titled “Step 3 - Define the materials”After confirming model changes, go to the Physics section to define model materials.

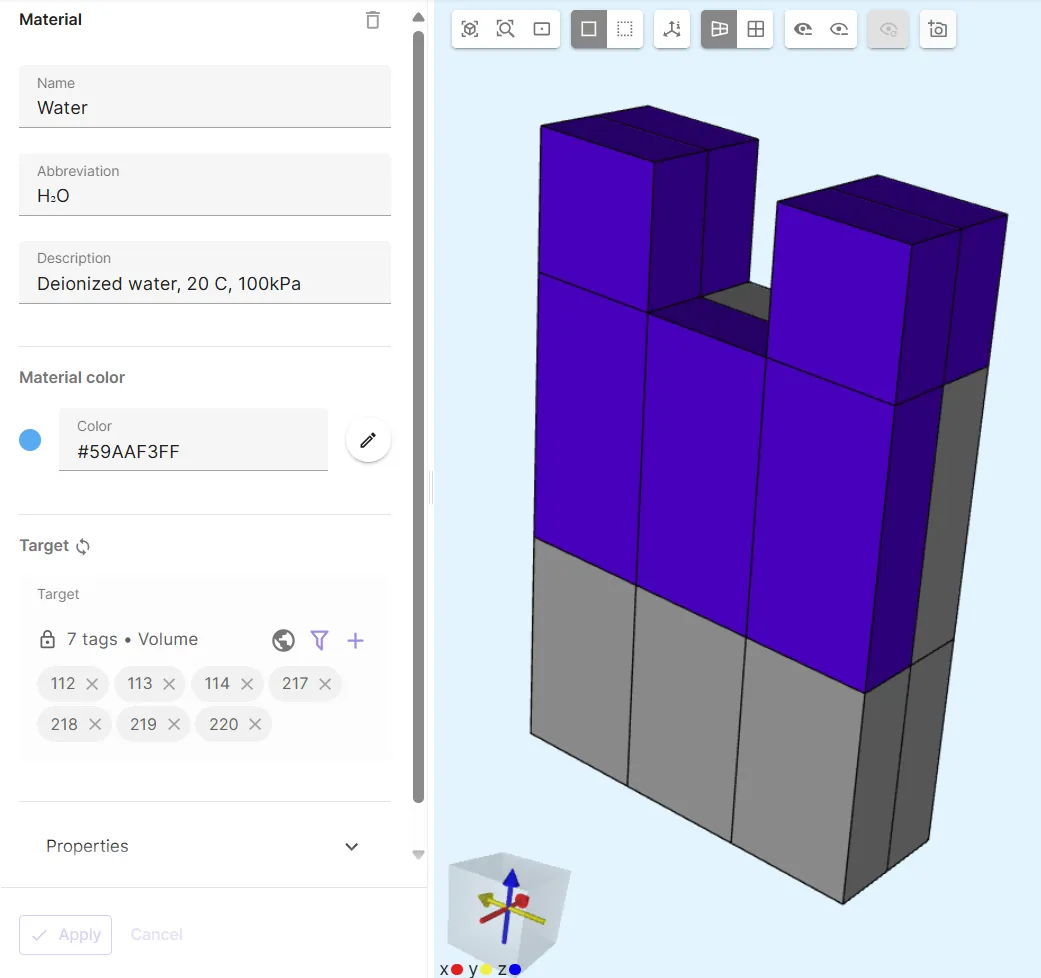

Material 1 - Water

Section titled “Material 1 - Water”Assign Water to 7 of the boxes as below (112-114, 217-220).

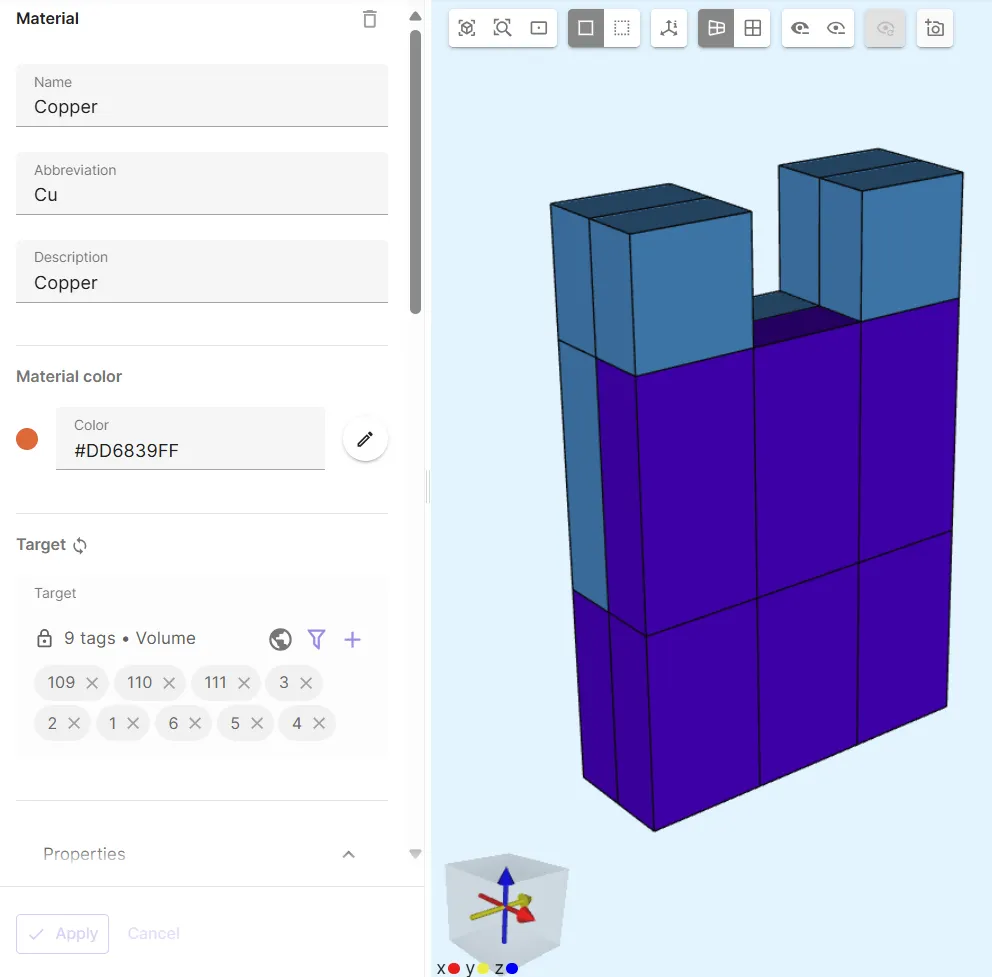

Material 2 - Copper

Section titled “Material 2 - Copper”Assign Copper to the remaining box volumes (1-6, 109-111).

Step 4 - Define the physics

Section titled “Step 4 - Define the physics”Go to the Physics section.

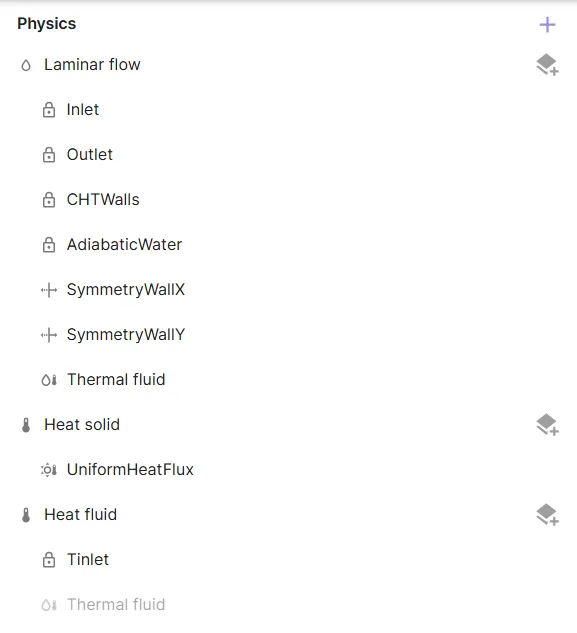

The Laminar flow, Heat solid and Heat fluid physics are required for CHT.

Add all of them before moving on to define interactions.

Physics 1 - Laminar flow

Section titled “Physics 1 - Laminar flow”-

As laminar flow target, select the water volumes (

112-114, 217-220). -

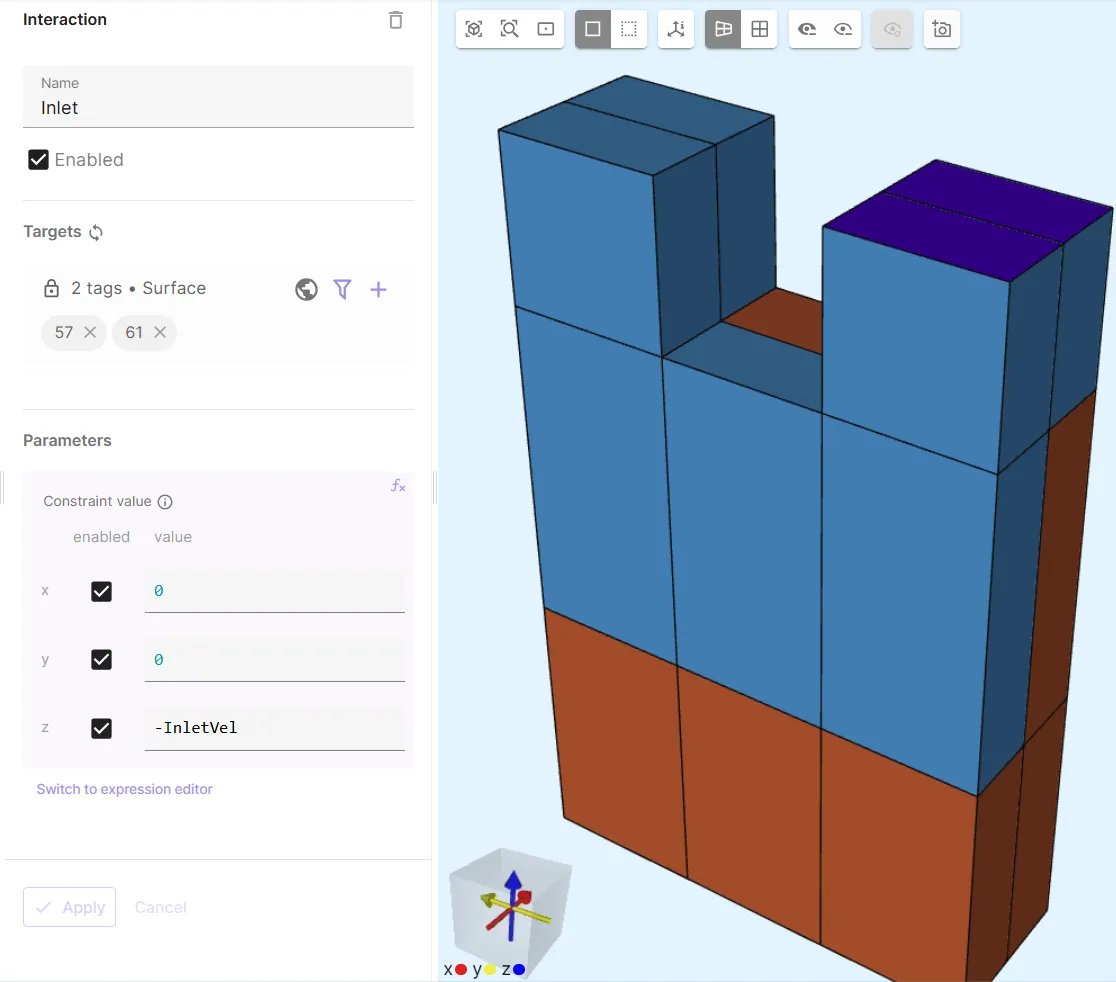

Add

Velocity constraintand name it asInlet:Name Interaction type Target Value Inlet Velocity constraintInlet surface ( 57, 61)[0; 0; -InletVel]

-

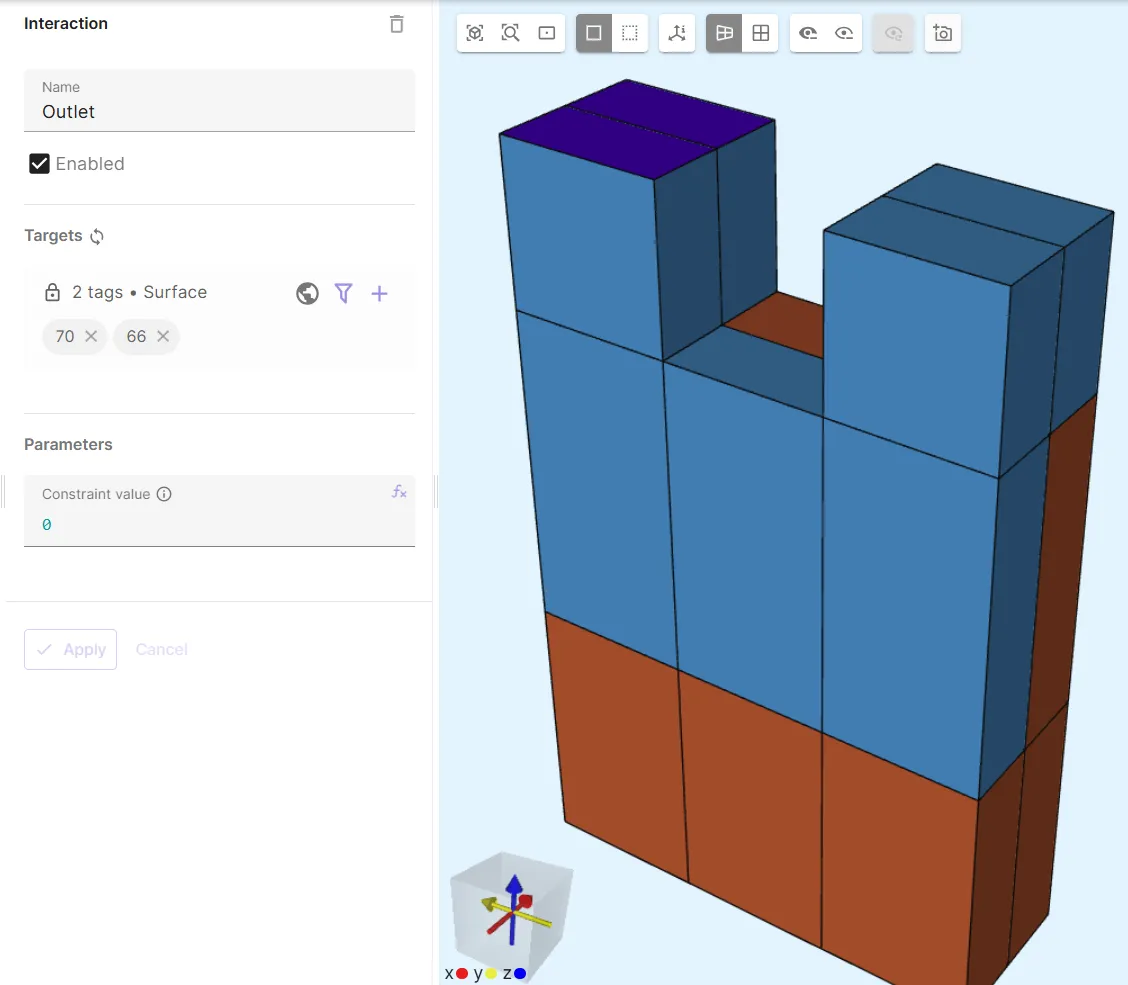

Add

Pressure constraintand name it asOutlet:Name Interaction type Target Value Outlet Pressure constraintOutlet surface ( 66, 70)0

-

Add

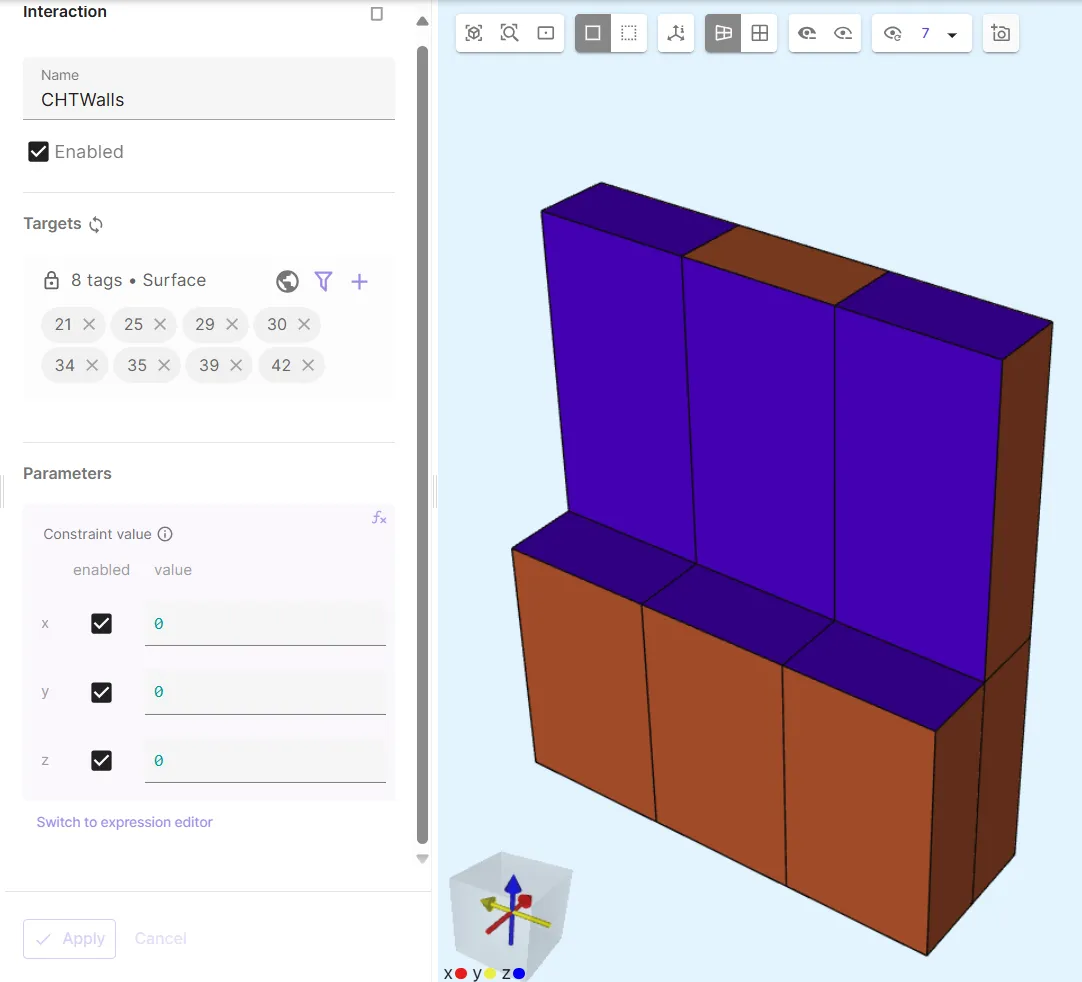

Velocity constraintand name it asCHTWalls:Name Interaction type Target Value CHTWalls Velocity constraintWater/copper boundary surfaces ( 21, 25, 29, 30, 34, 35, 39, 42)[0; 0; 0]

-

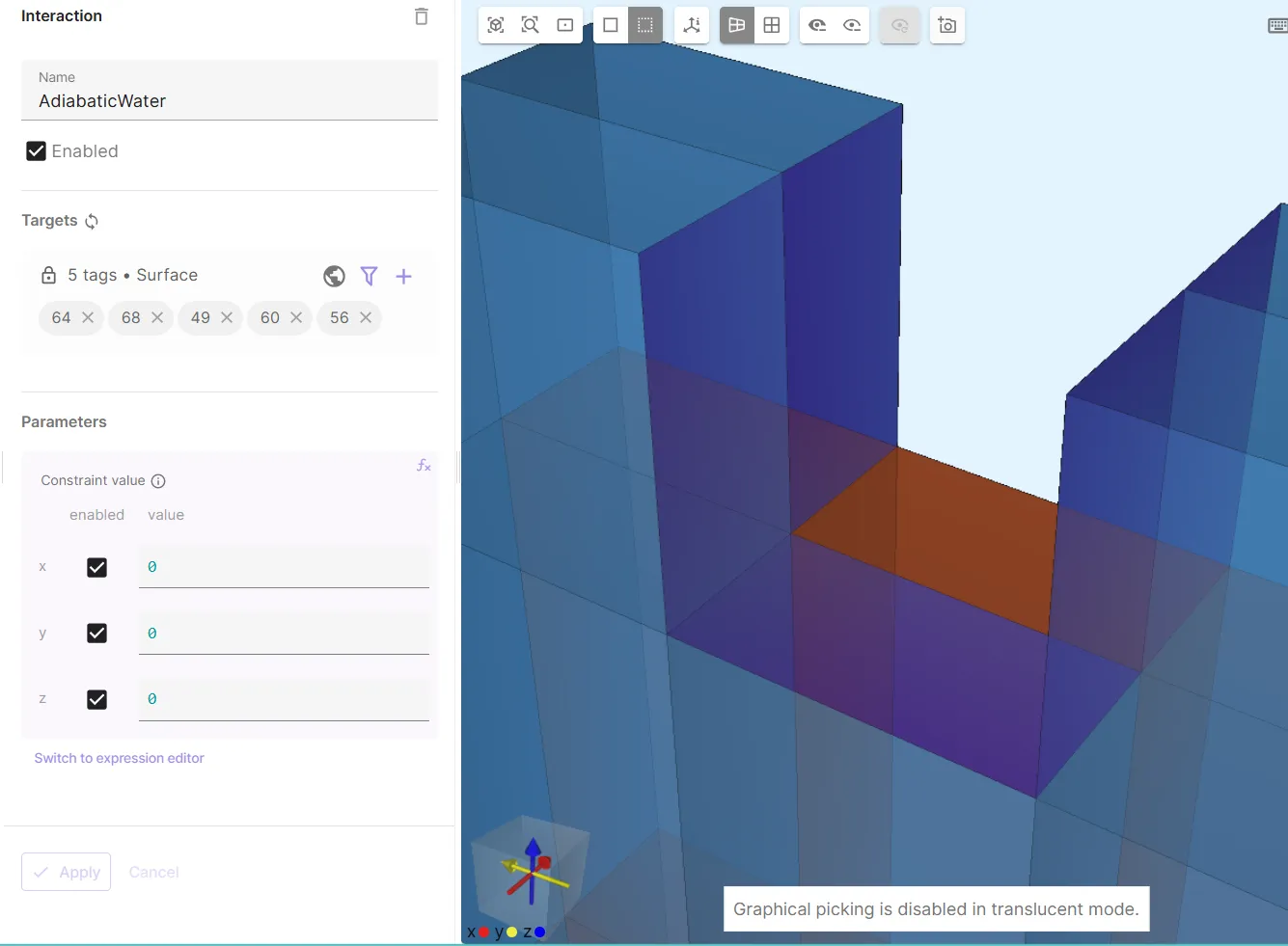

Add

Velocity constraintand name it asAdiabaticWater:Name Interaction type Target Value AdiabaticWater Velocity constraintWater inner boundary surfaces ( 49, 56, 60, 64, 68)[0; 0; 0]

-

Add

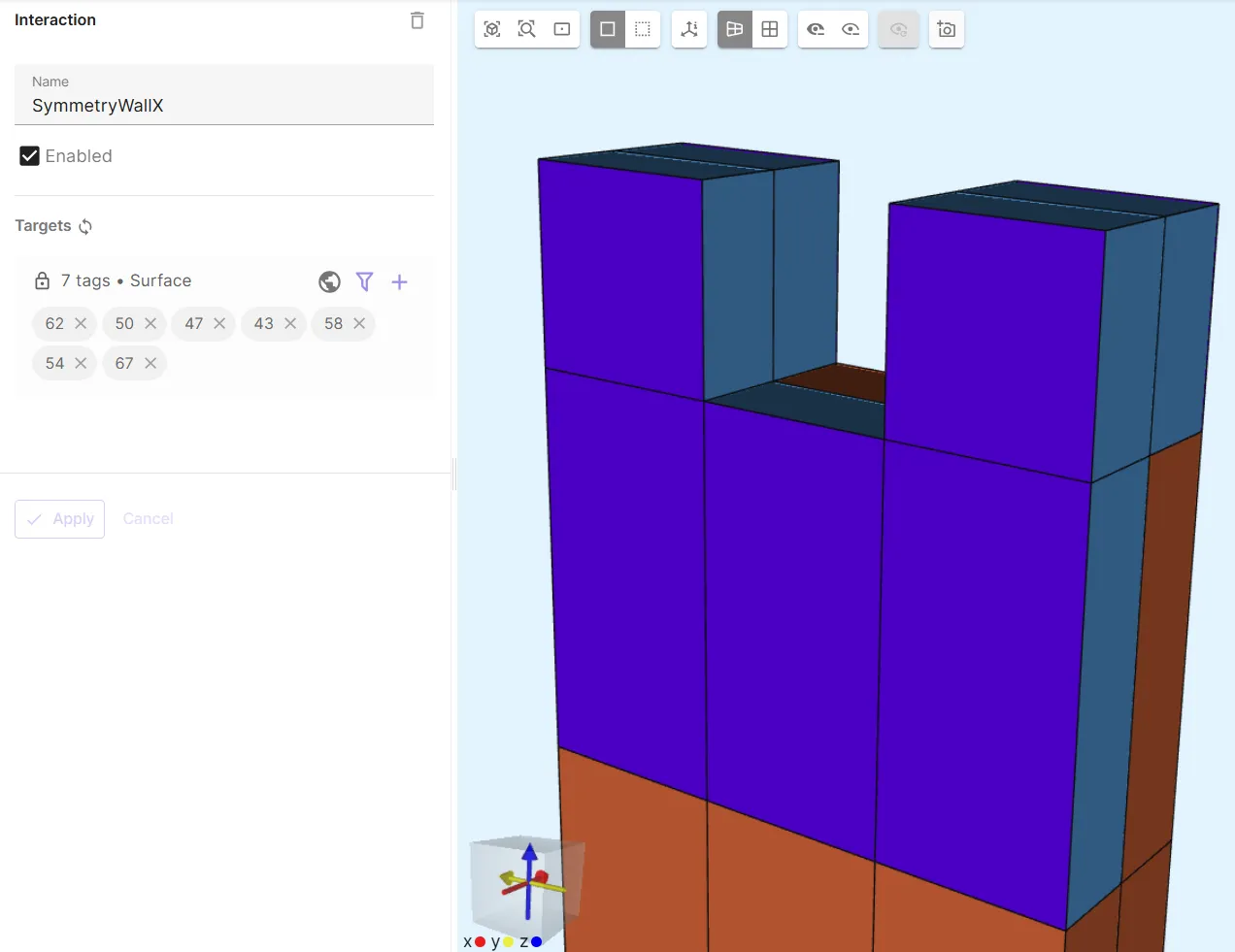

Velocity symmetryand name it asSymmetryWallX:Name Interaction type Target SymmetryWallX Velocity symmetryWater boundary surfaces perpendicular to X-axis ( 43, 47, 50, 54, 58, 62, 67)

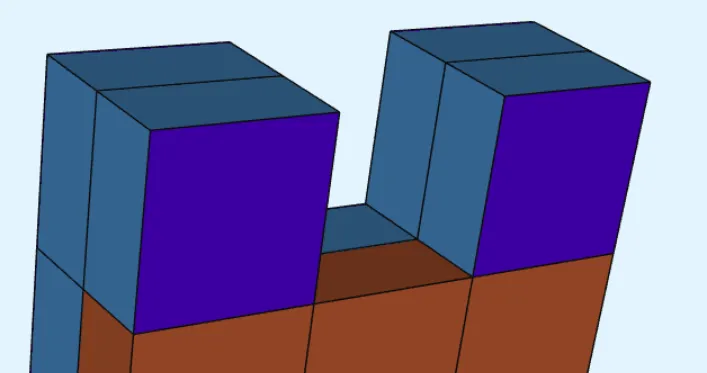

Remember to also select the water boundaries on the backside:

-

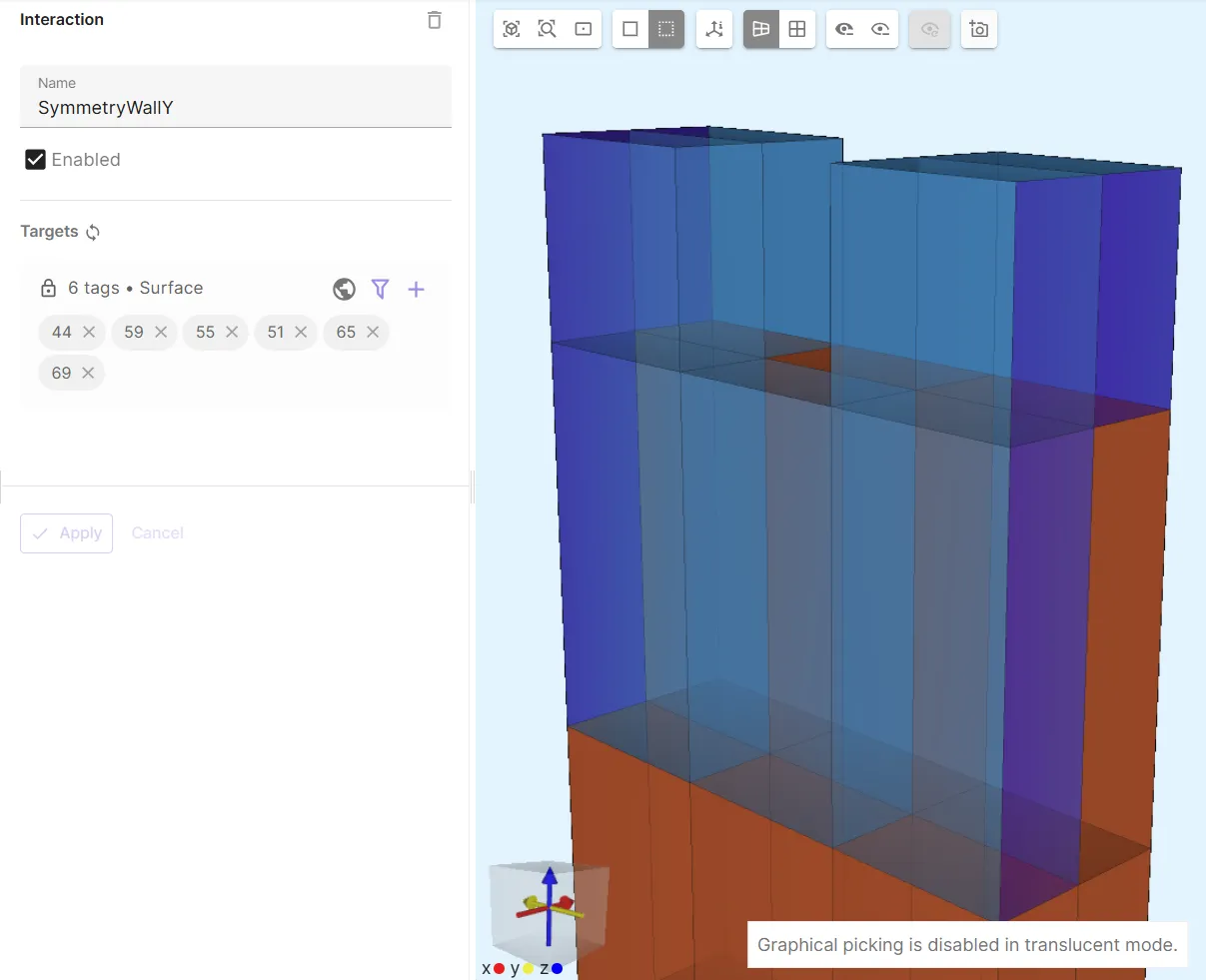

Add

Velocity symmetryand name it asSymmetryWallY:Name Interaction type Target SymmetryWallY Velocity symmetryWater boundary surfaces perpendicular to Y-axis ( 44, 51, 55, 59, 65, 69)

-

Add

Thermal fluidto couple Laminar flow with Heat fluid.

Physics 2 - Heat solid

Section titled “Physics 2 - Heat solid”-

As Heat solid target, select all copper volumes

1-6, 109-111. -

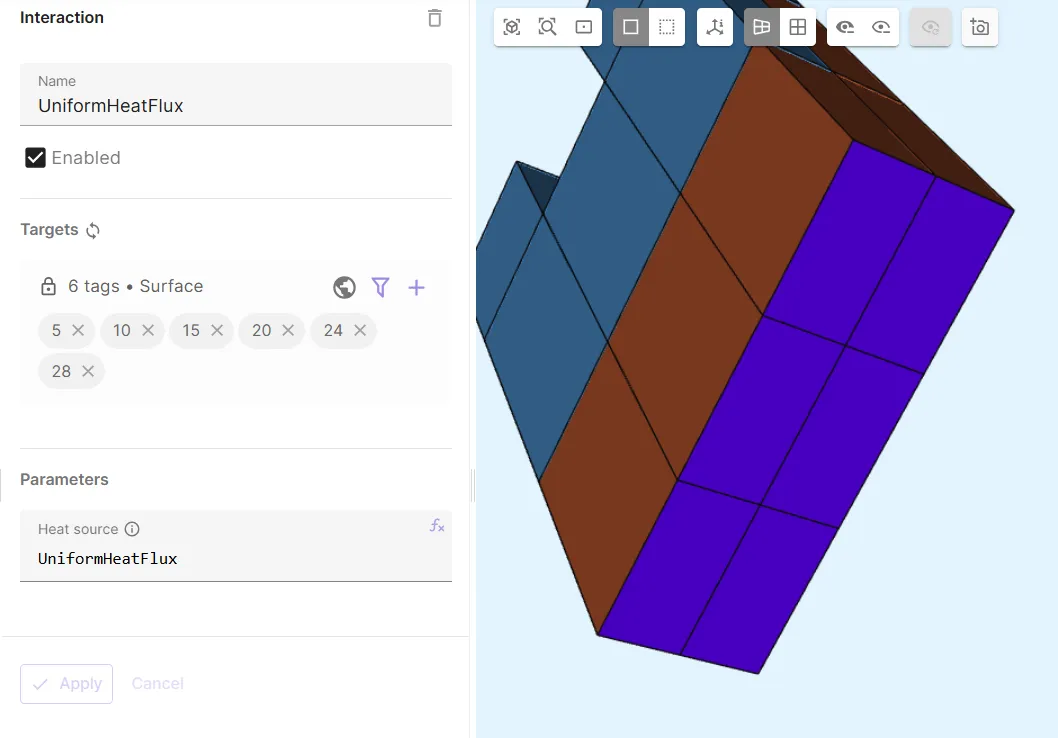

Add

Heat sourceand name it asUniformHeatFlux.Name Interaction type Target Heat source UniformHeatFlux Heat sourceBottom surface ( 5, 10, 15, 20, 24, 28)UniformHeatFlux

Physics 3 - Heat fluid

Section titled “Physics 3 - Heat fluid”-

As Heat fluid target, select the water region.

-

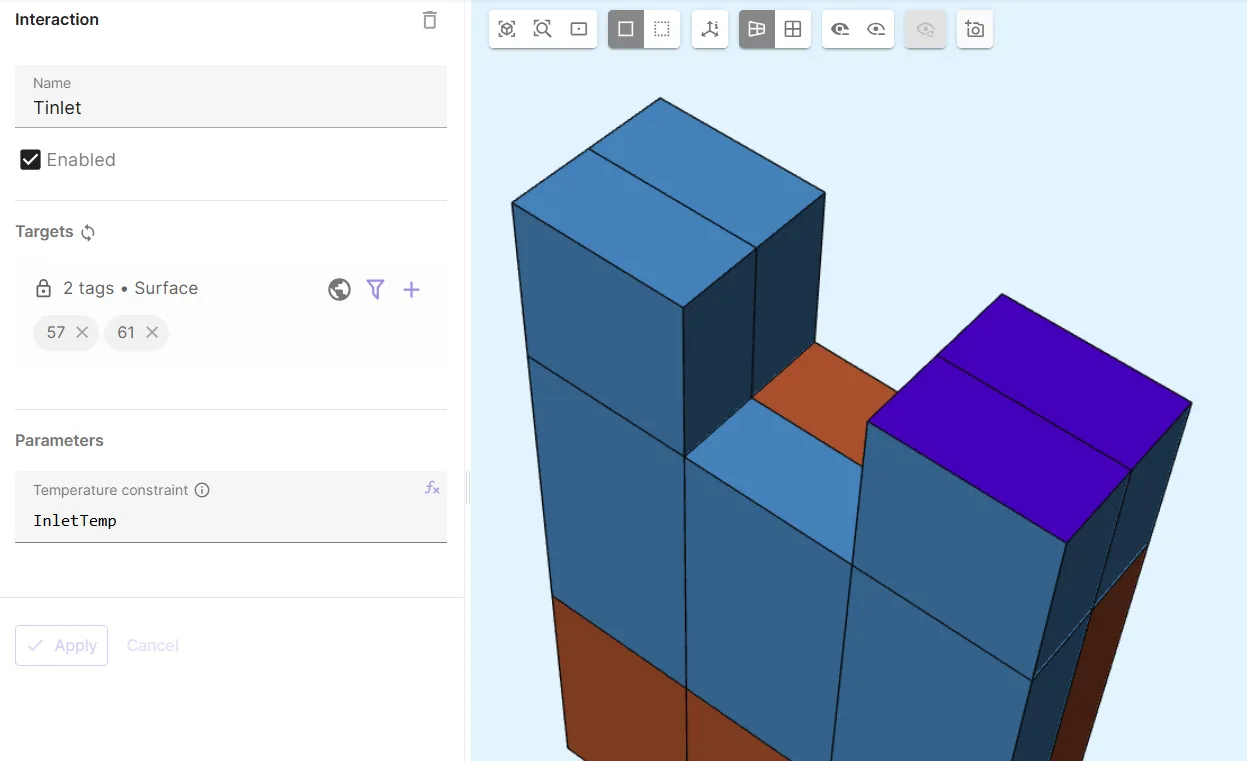

Add

Constraintand name it asTinlet.Name Interaction type Target Temperature constraint Tinlet ConstraintInlet surface ( 57, 61)InletTemp

Your physics are now defined. Before moving on, check that your physics tree matches the one below.

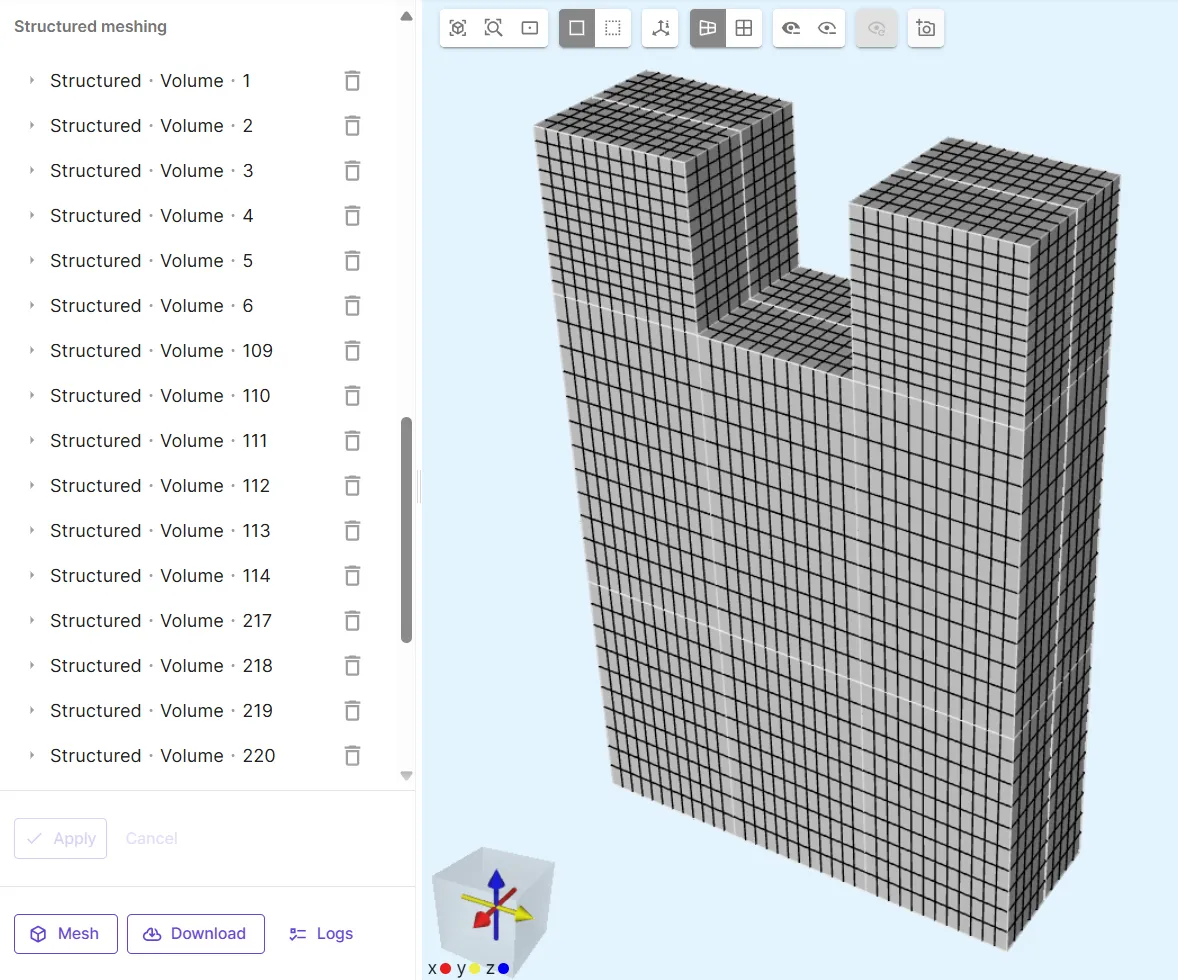

Step 5 - Generate the mesh

Section titled “Step 5 - Generate the mesh”Proceed to the Simulations section and create a new transfinite mesh:

-

Set Mesh quality to

Expert settings. -

Add transfinite mesh entities for each volume in the model, 16 in total.

-

Assign a unique volume as target for each entity, so that each volume is targeted once.

-

Apply the settings to save your work so far.

-

Assign lengths to your transfinite mesh entity segments according to this table:

Transfinite mesh entities Target volumes A Segments B Segments C Segments 1-6 Bottom layer boxes ( 1-6)m2(5e-5)m3(2.5e-5)m4(3e-5)7-12 Middle layer boxes ( 109-114)m1(5e-5)m3(2.5e-5)m4(3e-5)13-16 Top layer boxes ( 217-220)m3(2.5e-5)m3(2.5e-5)m4(3e-5)

Finished mesh:

Step 6 - Simulate

Section titled “Step 6 - Simulate”In the Simulations section, create a new simulation:

-

In Simulation settings:

- Set Analysis type to

Static. - Set Solver mode to

Direct solver.

- Set Analysis type to

-

As Mesh, select the mesh you created.

-

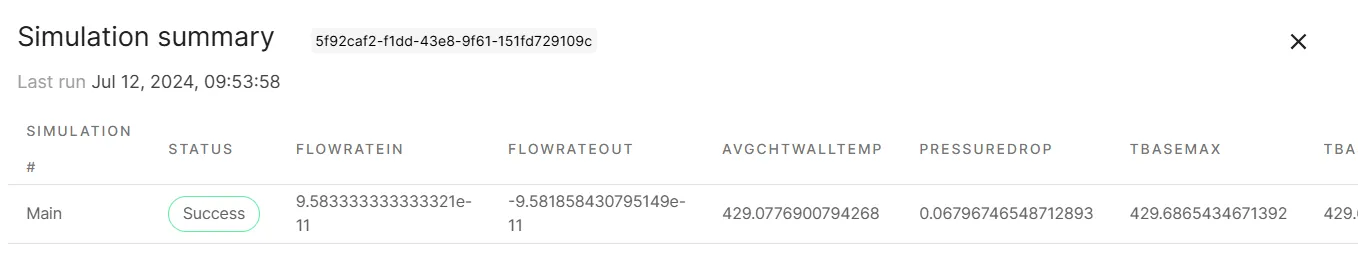

There are plenty of available options for Outputs. Choose those interesting to you from the table below:

Output type Name Output expression Field p pField V VField T TCustom value flowratein integrate(reg.inlet_target, transpose(V)*-normal(reg.water_target),2)Custom value flowrateout integrate(reg.outlet_target, transpose(V)*-normal(reg.water_target),2)Custom value AvgCHTWallTemp integrate(reg.chtwalls_target, T, 2)/integrate(reg.chtwalls_target, 1.0, 2)Custom value PressureDrop integrate(reg.inlet_target, p, 2)/integrate(reg.inlet_target, 1.0, 2)-integrate(reg.outlet_target, p, 2)/integrate(reg.outlet_target, 1.0, 2)Custom value Tbasemax maxvalue(reg.uniformheatflux_target, T, 2)Custom value Tbasemin minvalue(reg.uniformheatflux_target, T, 2)Custom value Tbaseavg integrate(reg.uniformheatflux_target, T, 2)/integrate(reg.uniformheatflux_target, 1.0, 2)Custom value ThermalResistance (maxvalue(reg.uniformheatflux_target, T, 2)-InletTemp)/(UniformHeatFlux*Ahsbase)Custom value PumpingPower (integrate(reg.inlet_target, p, 2)/integrate(reg.inlet_target, 1.0, 2)-integrate(reg.outlet_target, p, 2)/integrate(reg.outlet_target, 1.0, 2))*abs(integrate(reg.inlet_target, transpose(V)*-normal(reg.water_target),2))Custom value MeanAbsoluteTemperatureDeviation (abs(maxvalue(reg.uniformheatflux_target, T, 2) - integrate(reg.uniformheatflux_target, T, 2)/integrate(reg.uniformheatflux_target, 1.0, 2)) + abs(minvalue(reg.uniformheatflux_target, T, 2) - integrate(reg.uniformheatflux_target, T, 2)/integrate(reg.uniformheatflux_target, 1.0, 2)))/2.0

You can run the simulation after selecting options and outputs.

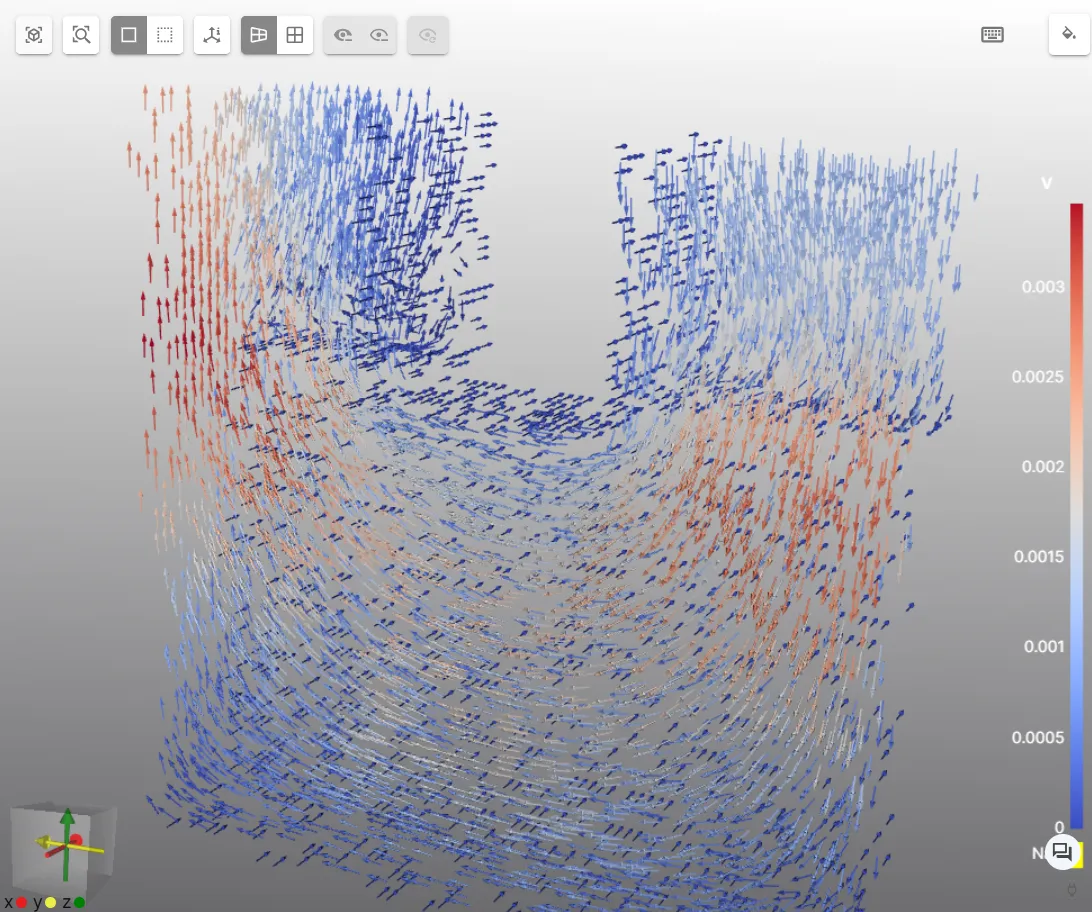

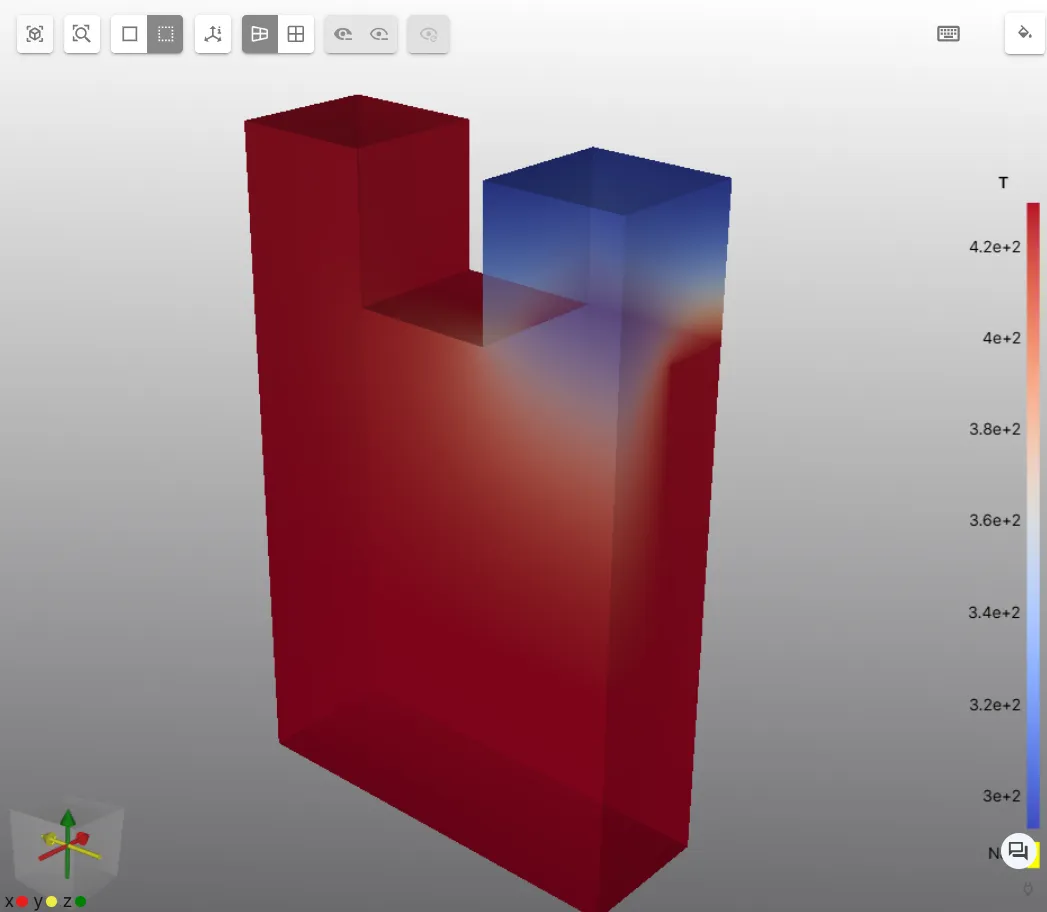

Step 7 - Results

Section titled “Step 7 - Results”In the Simulations section, you can add visualizations to see field output results.

Some examples are given below.

- Velocity field visualization:

- Temperature field visualization:

In a static simulation, only one data point is extracted for each custom value output. You can see custom value output data in the Summary:

To extract multiple values for custom value outputs to create plots, use a sweep or a transient simulation with enough sweep/time-steps.

References

Section titled “References”[1] K. Tang, G. Lin, Y. Guo, J. Huang, H. Zhang, J. Miao. Simulation and optimization of thermal performance in diverging/converging manifold microchannel heat sink. International Journal of Heat and Mass Transfer, Vol 200, 2023. https://doi.org/10.1016/j.ijheatmasstransfer.2022.123495.