Bending of a cantilever beam

In this tutorial, the bending of a cantilever beam is simulated.

A cantilever is a rigid structure that extends horizontally and is unsupported at one end 1. It is widely used in construction and serves as a baseline simulation for structural mechanics.

Model definition

Section titled “Model definition”The model comprises a small aluminium beam built from a single box element. The beam is clamped from one of its end surfaces, and extends horizontally like a flagpole attached to a wall.

A load is evenly applied to the top surface of the beam, bending it downwards. The maximum Z-displacement is solved during simulation.

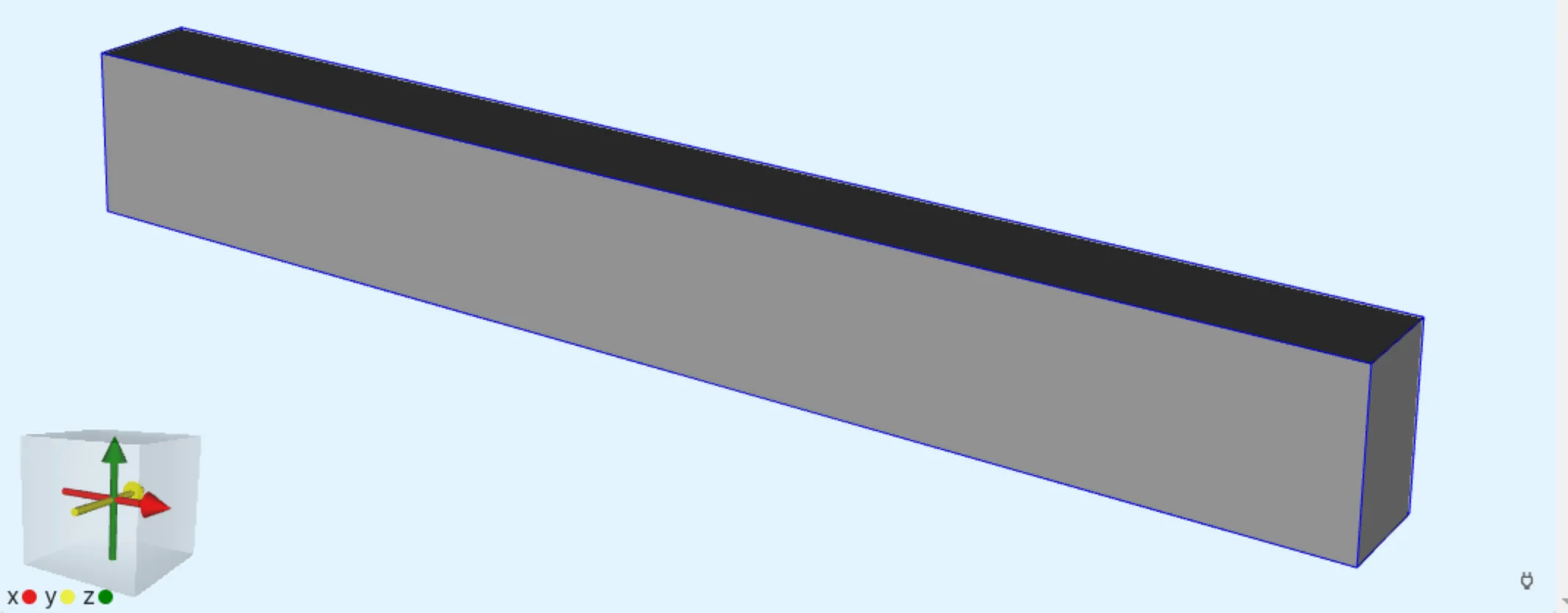

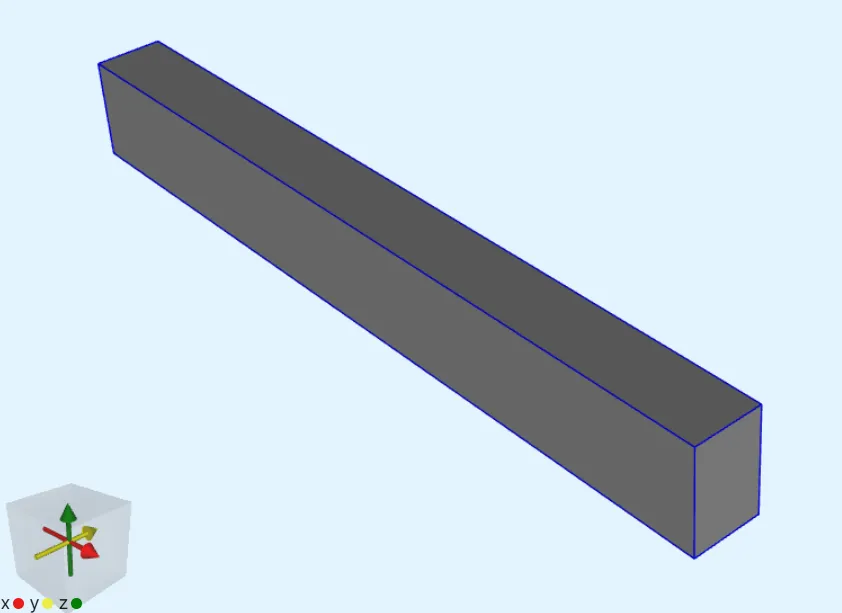

Model geometry

Section titled “Model geometry”| Name | Element type | XYZ dimensions [mm] |

|---|---|---|

| Cantilever beam | Box | 24 x 2 x 3 |

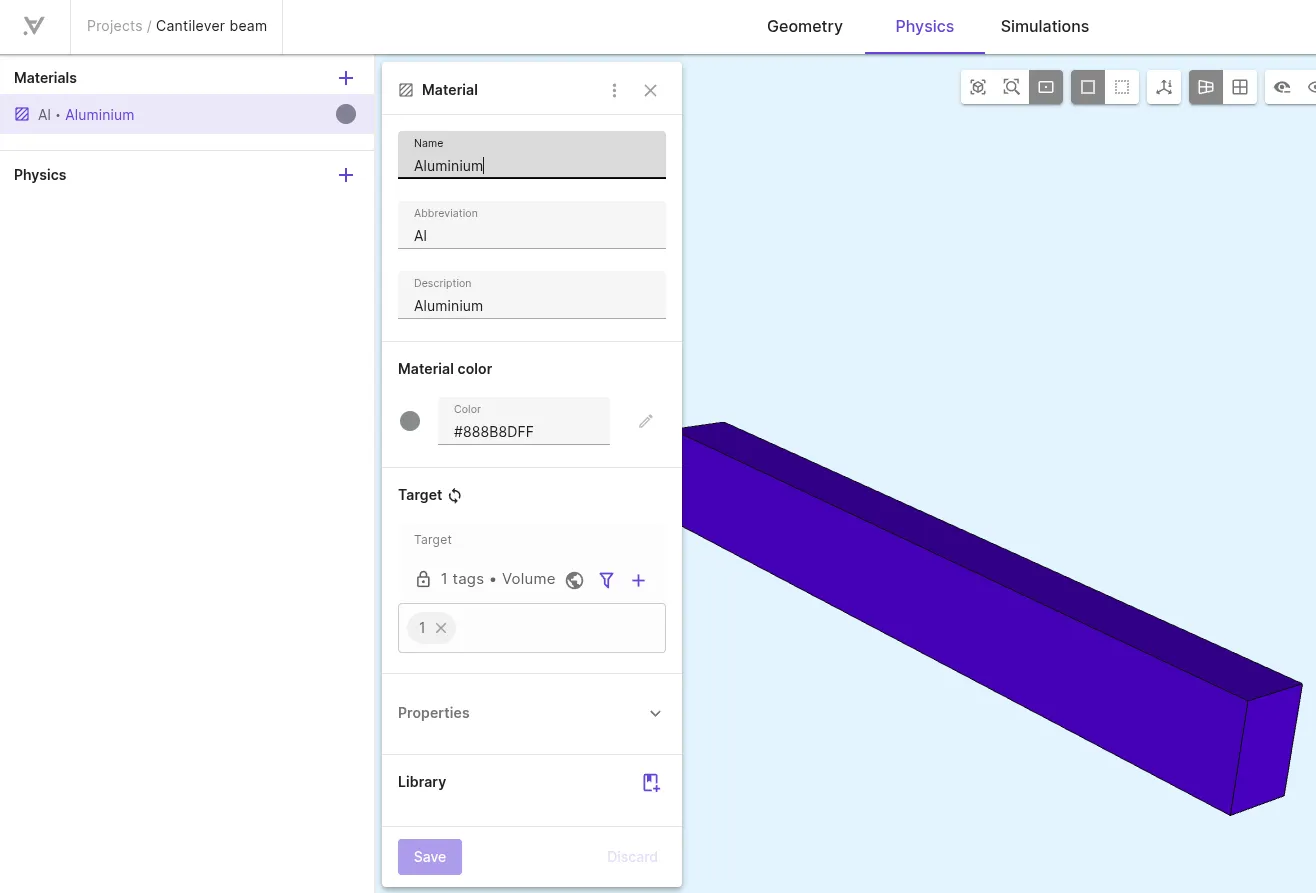

Material Data

Section titled “Material Data”Aluminium

Section titled “Aluminium”| Property | Value |

|---|---|

| Poisson’s ratio | 0.32 |

| Young’s modulus [Pa] | 68e9 |

Boundary conditions

Section titled “Boundary conditions”| Name | Type | Value [X, Y, Z] |

|---|---|---|

| left X-plane | Clamp | [0, 0, 0] |

| top Z-plane | Load [N] | [0, 0, -1000] |

Output Results

Section titled “Output Results”Maximum Z-displacement.

Step-by-step guide

Section titled “Step-by-step guide”Below, you’ll find a detailed step-by-step tutorial on how to set up a cantilever beam simulation in Quanscient Allsolve.

Step 1 - Build the geometry

Section titled “Step 1 - Build the geometry”-

Start with a new project and name it

Cantilever beam. -

Start out with a

boxelement. A1 x 1 x 1m box is built by default. -

Edit the size of the box in settings:

Name Element type Center point [m] Size [m] Rotation [deg] box Box X: 0X: 24e-3X: 0Y: 0Y: 2e-3Y: 0Z: 0Z: 3e-3Z: 0 -

Rebuild the box with correct dimensions.

-

Confirm model changes before moving on.

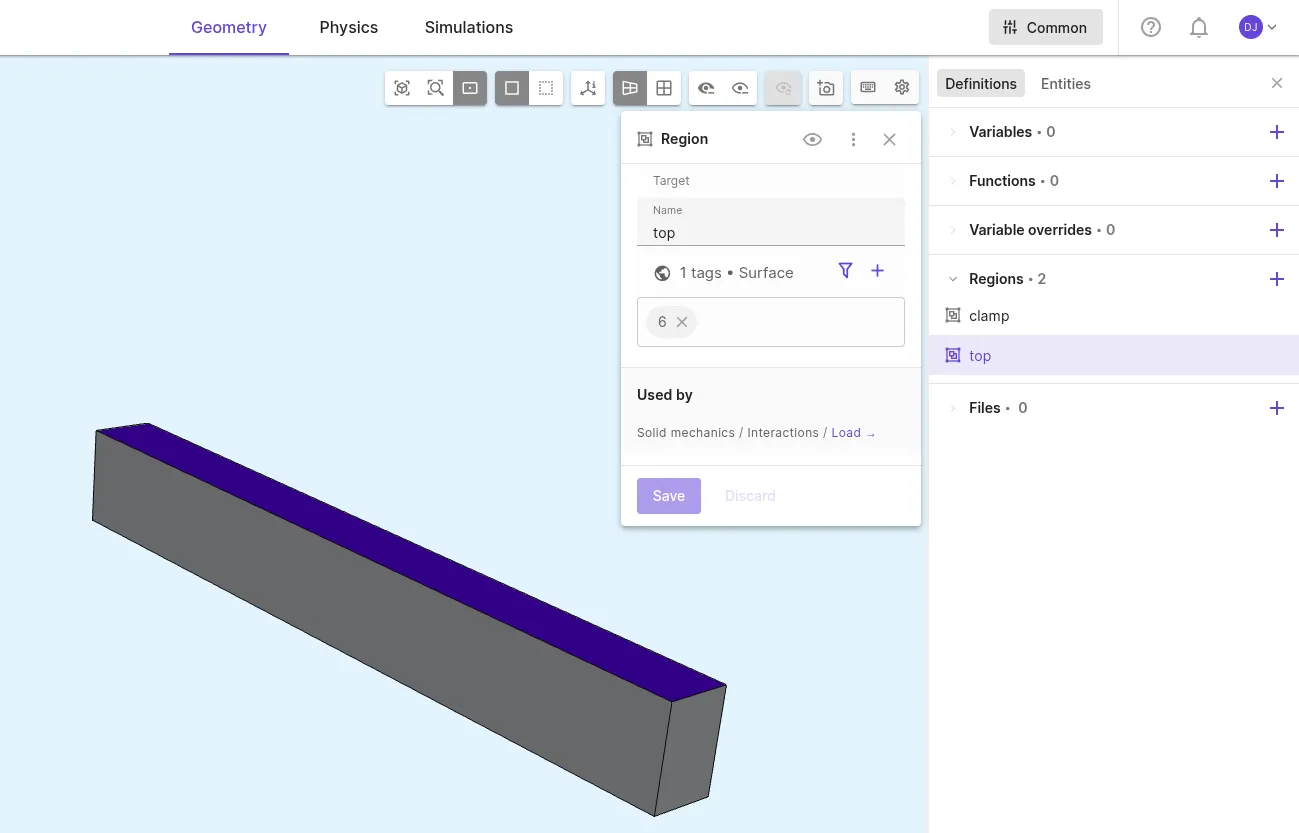

Step 2 - Define shared regions

Section titled “Step 2 - Define shared regions”-

Go to the

Commonsidebar. -

Define shared regions:

Name Region type Target clampSurface X direction bottom surface ( 1)topSurface Z direction top surface ( 6)

Step 3 - Define the material

Section titled “Step 3 - Define the material”Assign the predefined Aluminium material to the beam volume (1).

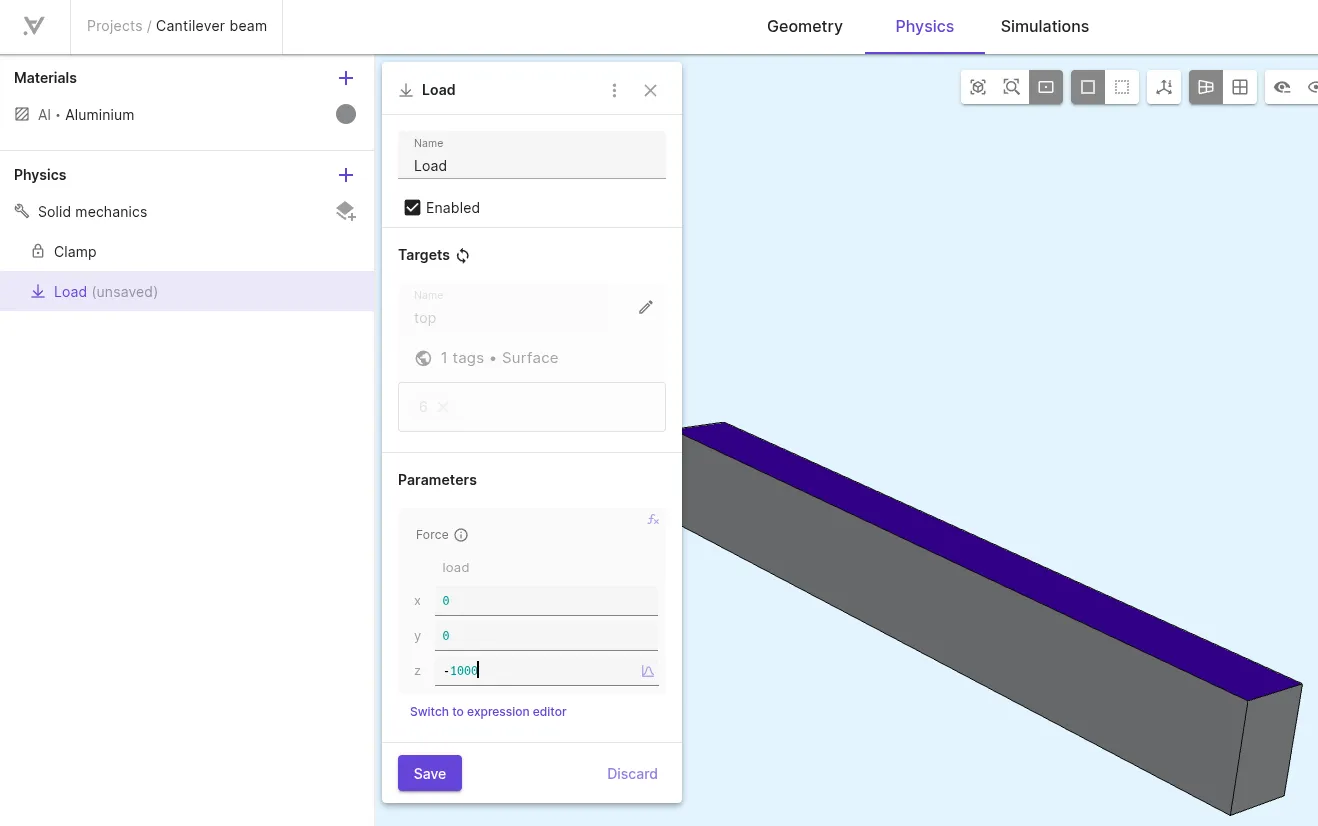

Step 4 - Define the physics & boundary conditions

Section titled “Step 4 - Define the physics & boundary conditions”-

Go to the

Physicssection. -

Add the

Solid mechanicsphysics.Not selecting a target for a physics makes it default to the whole model. Let solid mechanics target default to the beam volume.

Physics Target Solid mechanics Beam (volume 1) -

Add a

Clampinteraction to Solid mechanics.Name Interaction type Target Clamp Clampclampshared region (surface1)This boundary condition will constraint all components of the displacement vector in the targeted region to zero displacement: , , .

-

Add a

Loadinteraction to Solid mechanics.Name Interaction type Target Value [X; Y; Z] Load Loadtopshared region (surface6)[0; 0; -1000]

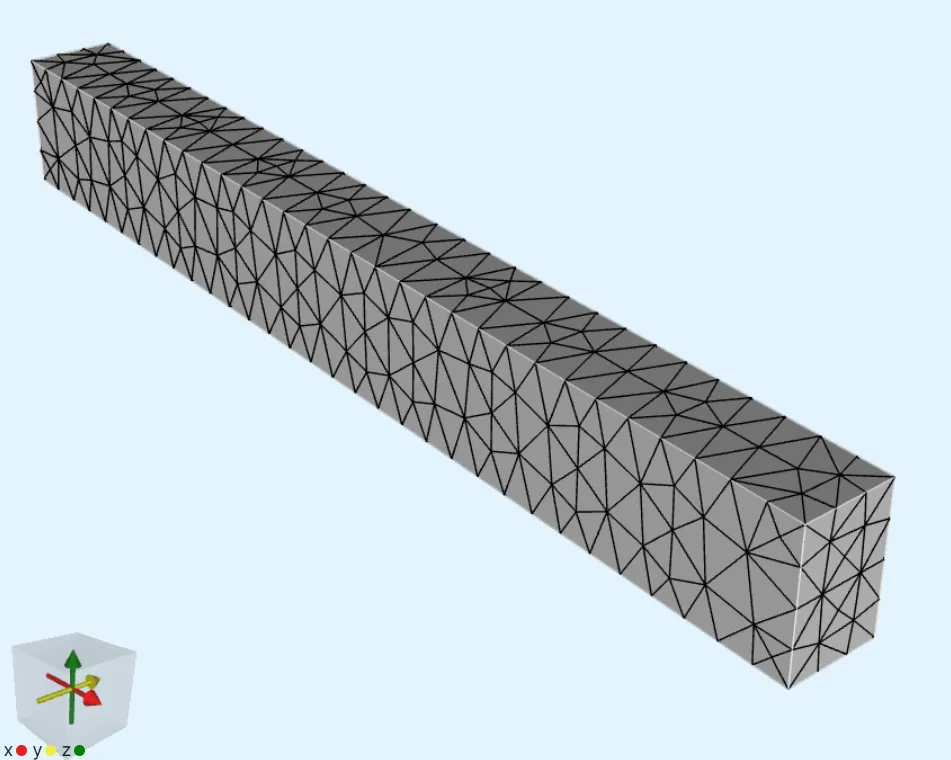

Step 5 - Generate the mesh

Section titled “Step 5 - Generate the mesh”-

Proceed to the

Simulationssection. -

Generate a new mesh with default settings and check the preview.

Step 6 - Apply simulation settings & run

Section titled “Step 6 - Apply simulation settings & run”-

Create a new simulation.

-

Set Analysis Type to

Static. -

Select the mesh you generated as the mesh for your simulation.

-

Add the displacement field output

u. -

Run the simulation.

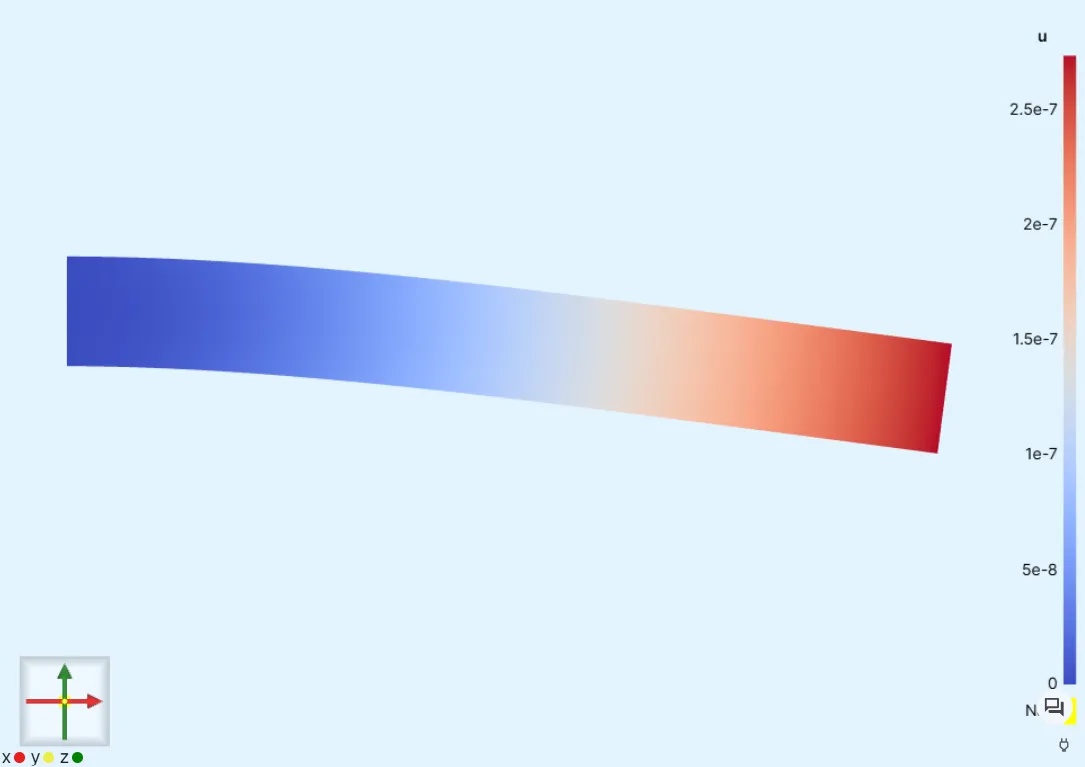

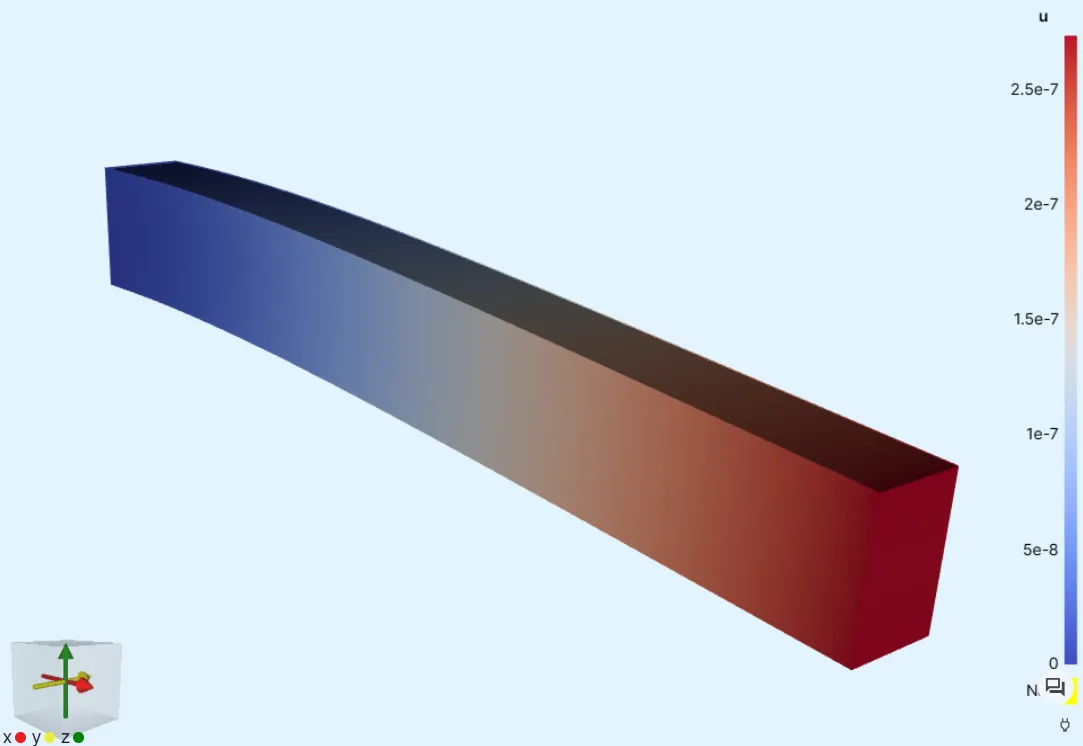

Step 7 - Visualize results

Section titled “Step 7 - Visualize results”-

Add a visualization for the

ufield. -

Add

Warpto the visualization and activate it. -

Click on the Refresh icon next to Warp scale factor.

-

Render the deformed geometry scaled up according to the scale factor.

Here, the scale factor is

8772.