Static heat transfer in solid materials - NAFEMS Benchmark

In this tutorial, a NAFEMS benchmark test for thermal analysis is set up and simulated. 1

Model definition

Section titled “Model definition”A steady-state thermal analysis is performed with different boundary conditions (BCs) including adiabatic (insulated or zero heat flux), Dirichlet BCs, and finite heat flux by natural convection specified by a known heat transfer coefficient.

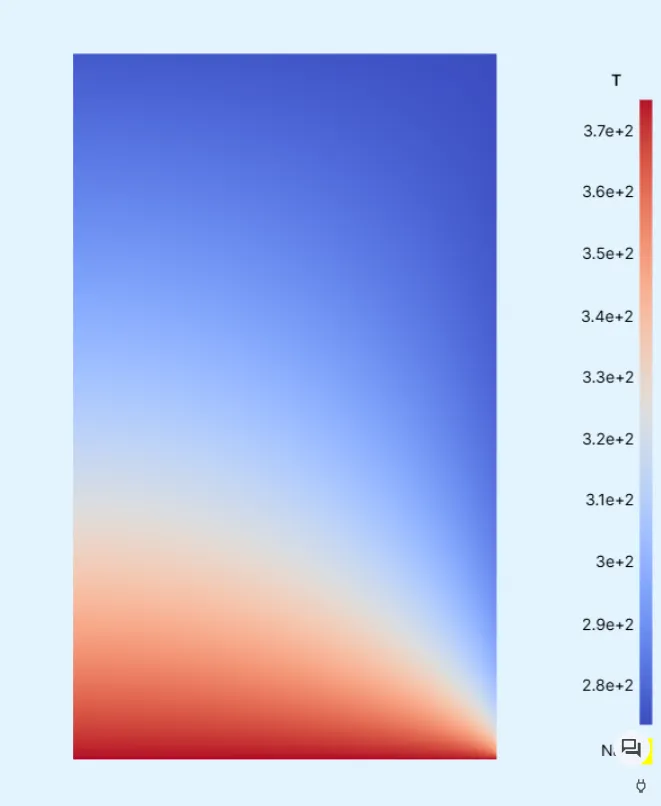

The result is a steady-state temperature distribution in the spatial domain. The image below shows the schematic of the spatial domain with BCs.

Output Results

Section titled “Output Results”- Temperature at coordinates , which is on the right boundary exposed to ambient. The benchmark value is .

Material Data

Section titled “Material Data”| Property | Value | Unit |

|---|---|---|

| Density | ||

| Specific heat capacity | ||

| Thermal conductivity |

Boundary conditions

Section titled “Boundary conditions”| Name | Type | Value | Unit |

|---|---|---|---|

| left boundary | heat flux | ||

| bottom boundary | temperature | ||

| right boundary | heat flux | ) | |

| top boundary | heat flux | ) | |

| ambient | temperature | ||

| natural convection | heat transfer coefficient | ||

| front boundary | heat flux | ||

| back boundary | heat flux |

Step-by-step guide

Section titled “Step-by-step guide”Here you’ll find a detailed step-by-step tutorial on how to set up a NAFEMS thermal analysis simulation in Quanscient Allsolve.

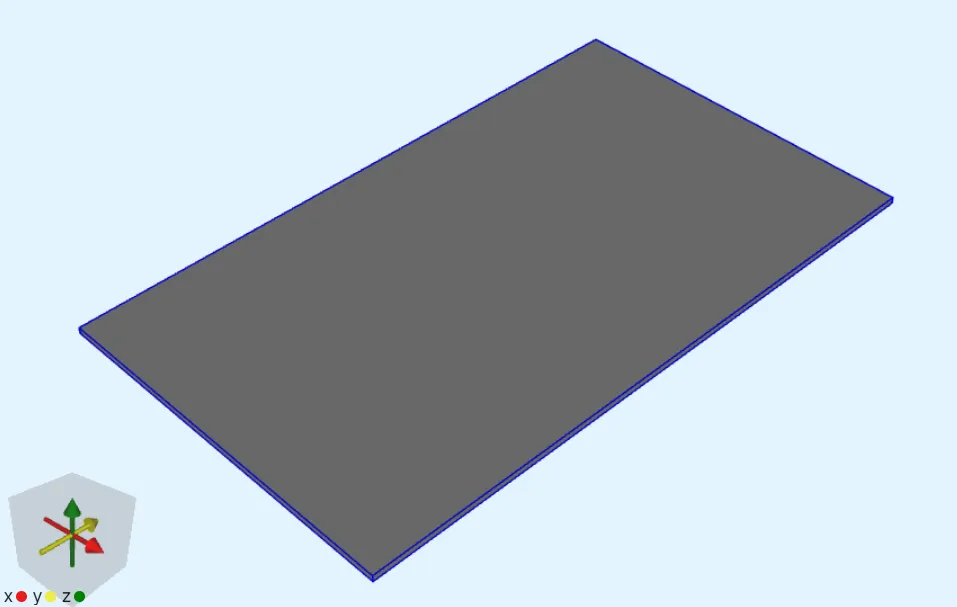

Step 1 - Build the geometry

Section titled “Step 1 - Build the geometry”-

Create a new project and name it as

NAFEMS 2D Heat Transfer Benchmark -

Start off with a

boxelement. -

Edit the size of the box:

Name Element type Center point [m] Size [m] Rotation [deg] box Box X: 0X: 0.6X: 0Y: 0Y: 1.0Y: 0Z: 0Z: 0.01Z: 0

Step 2 - Define shared regions

Section titled “Step 2 - Define shared regions”-

Proceed to the

Commonsidebar. -

Define shared regions:

Region name Region type Target ConstantTemperatureSurface Y bottom surface 3NaturalConvectionSurface X and Y top surfaces 2, 4

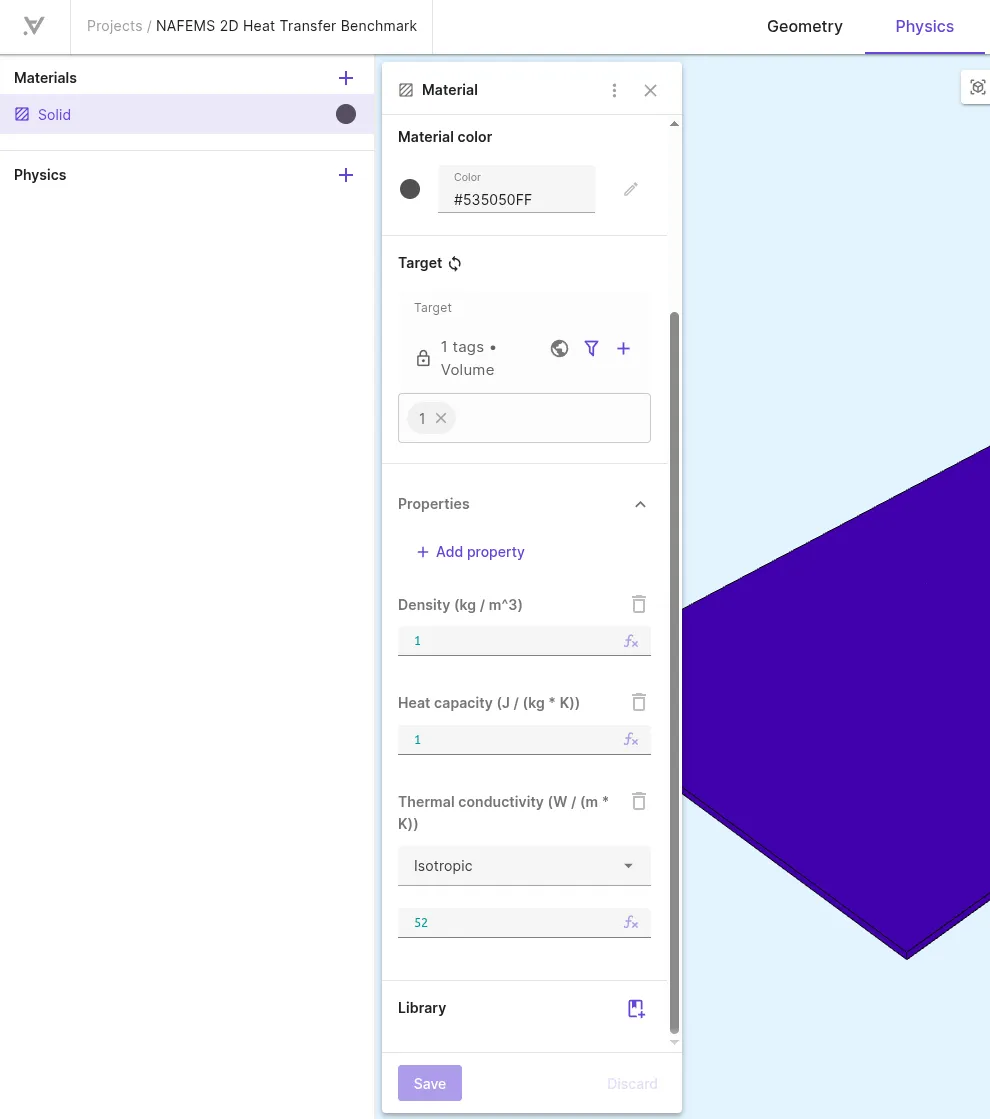

Step 3 - Define the material

Section titled “Step 3 - Define the material”-

Create a new material in the

Physicssection:Name Abbreviation Description Color Target Solid NAFEMS material Dark grey Volume 1 -

Add properties to the material:

Property Value Density 1Heat capacity 1Thermal conductivity 52

Step 4 - Define variables

Section titled “Step 4 - Define variables”Define variables:

| Name | Description | Expression |

|---|---|---|

| h | Heat transfer coefficient (W/m^2/K) | 750 |

| Tamb | Ambient temperature (K) | 273.15 |

Step 5 - Define physics and boundary conditions

Section titled “Step 5 - Define physics and boundary conditions”-

Go to the

Physicssection. -

Add the

Heat solidphysics.Physics Target Heat solid Default (volume 1) -

Add a

Constraintinteraction to Heat solid:Name Interaction type Target Value Constraint ConstraintConstantTemperatureshared region (surface3)375.15 -

Add a

Heat sourceinteraction to Heat solid:Name Interaction type Target Value Heat source Heat sourceNaturalConvectionshared region (surfaces2, 4)-h * (T - Tamb)

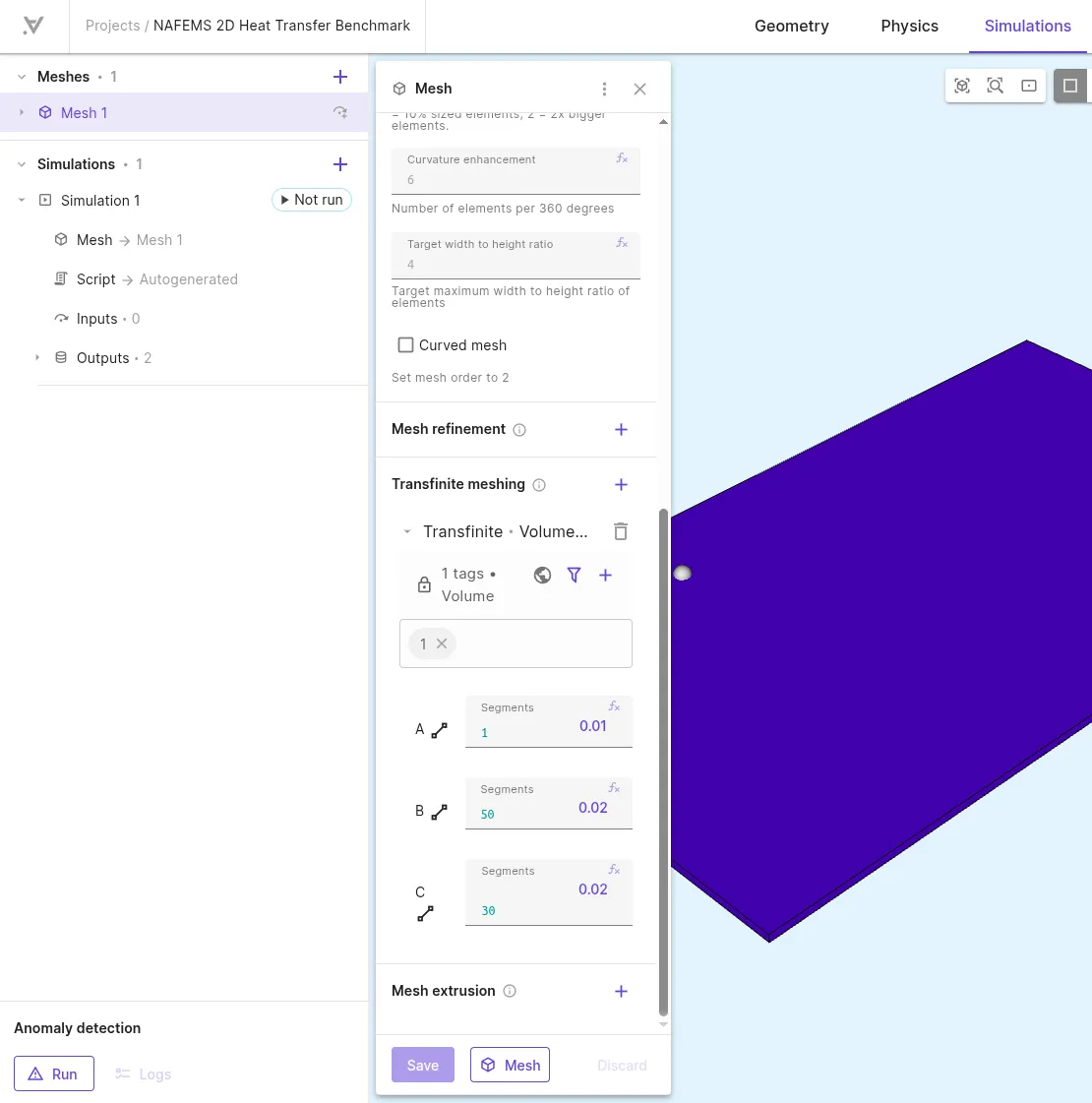

Step 6 - Generate the mesh

Section titled “Step 6 - Generate the mesh”-

Go to the

Simulationssection. -

Create a new mesh.

-

Set Mesh quality to

Expert settings. -

Scroll down to Transfinite meshing and add a

Volumestructured mesh entity: -

Select volume

1as the structured mesh entity target.Structured mesh entity type Target Segments Volumevolume 1A: 1B: 50C: 30With these options, only one element is created in the Z-direction to mimic a 2-dimensional domain. Elements of length are created in the X- and Y-directions.

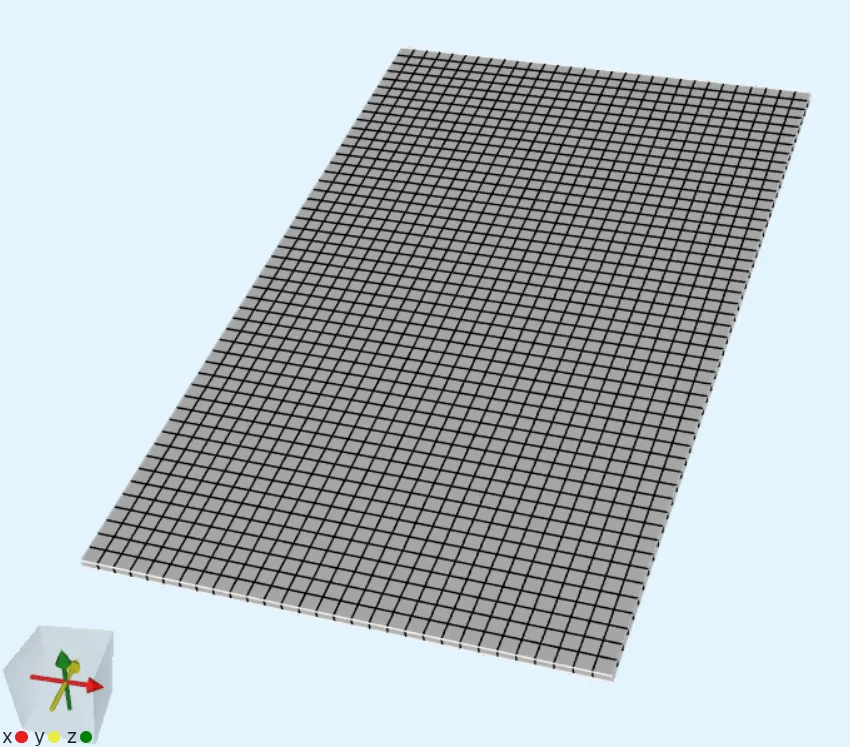

-

Generate the mesh and check the preview.

Step 7 - Apply simulation settings

Section titled “Step 7 - Apply simulation settings”-

Add a new simulation.

-

Set Analysis type to

Static. -

Select the mesh you created in Step 6 as the mesh for your simulation.

-

Add a

Ttemperature field output. -

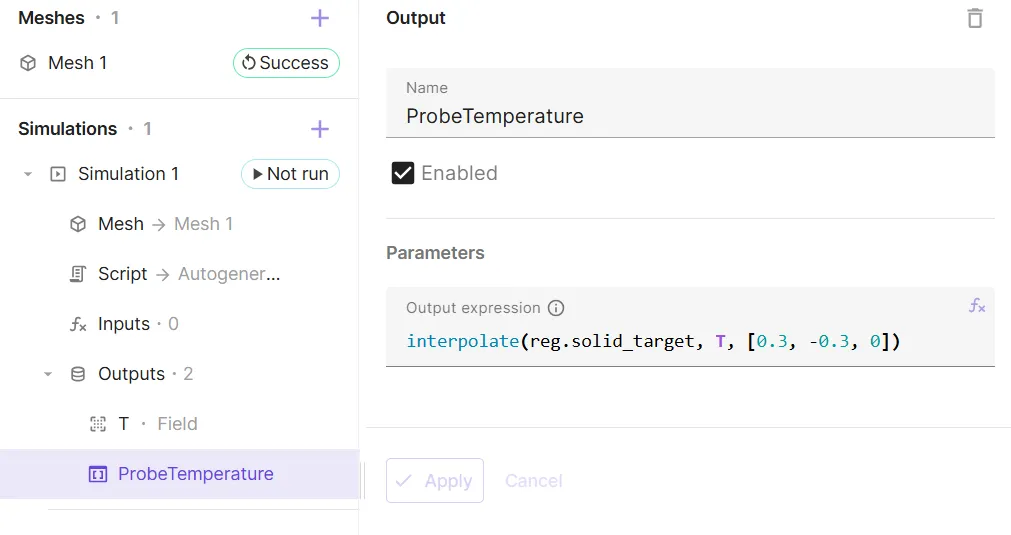

Add a custom value output, which interpolates temperature at coordinates :

Name Output expression ProbeTemperature interpolate(reg.solid_target, T, [0.3, -0.3, 0])

-

Run the simulation.

-

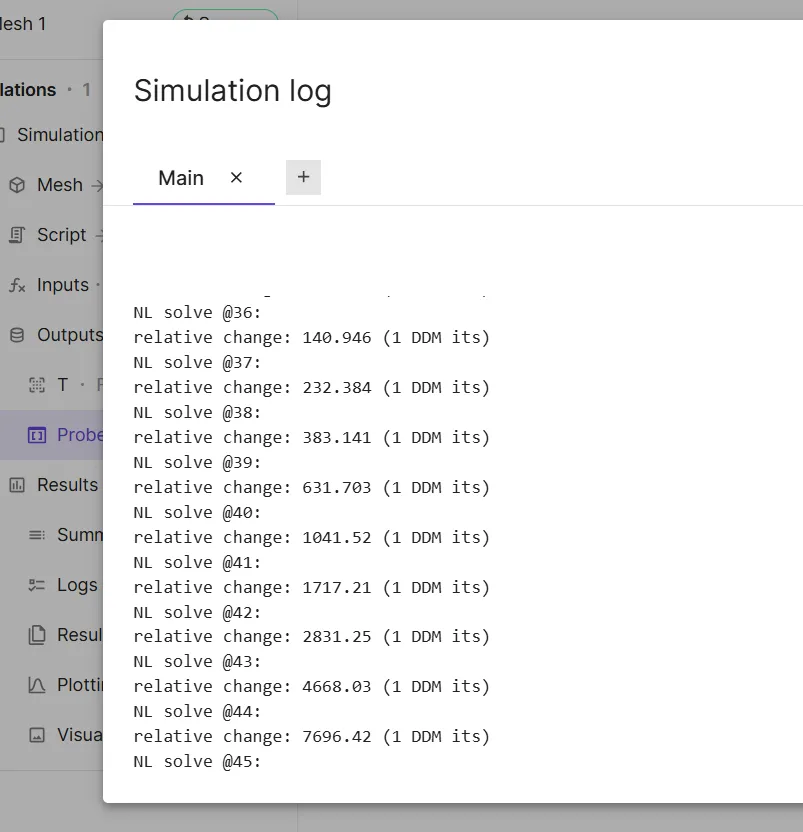

To check the progress of the simulation, check the

Logs. -

The relative change is increasing with each iteration, so the simulation will not converge.

Abortthe simulation.

Step 8 - Edit the script

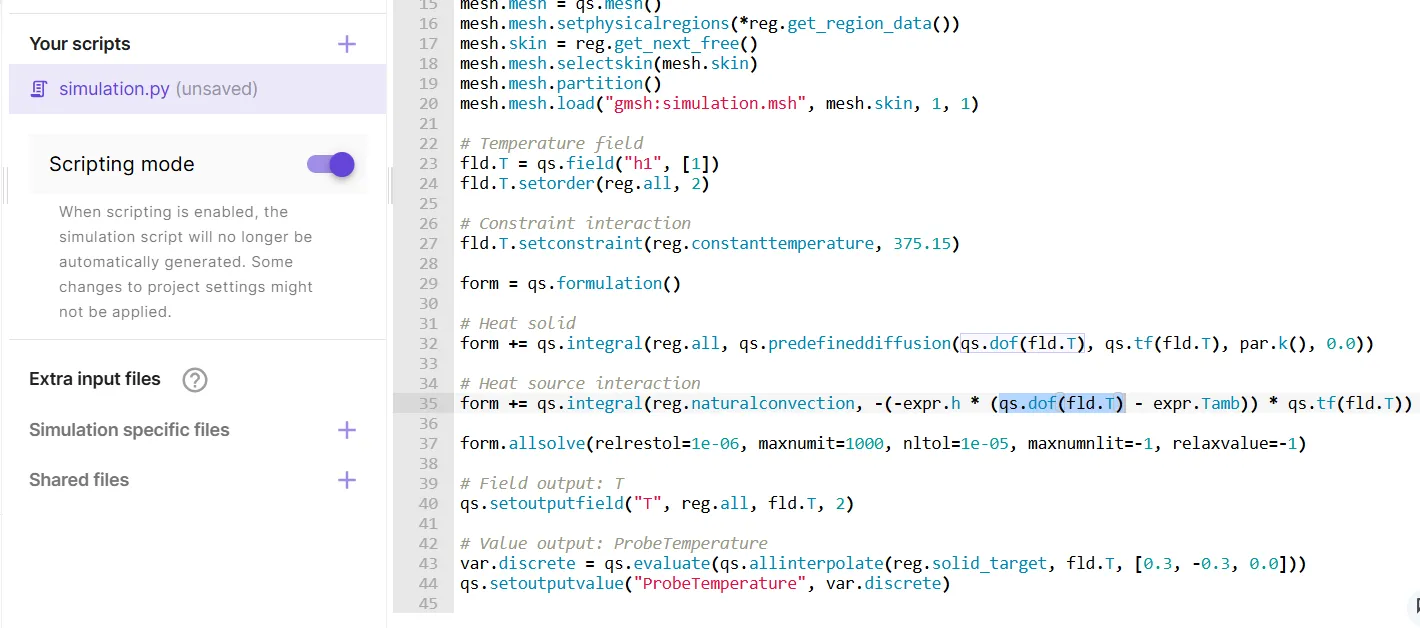

Section titled “Step 8 - Edit the script”To solve the convergence issue, the Script needs some modification.

-

Open the

Scriptand toggle onScripting mode. -

Change

fld.Tin the Heat source interaction formulation toqs.dof(fld.T). Save the script.

-

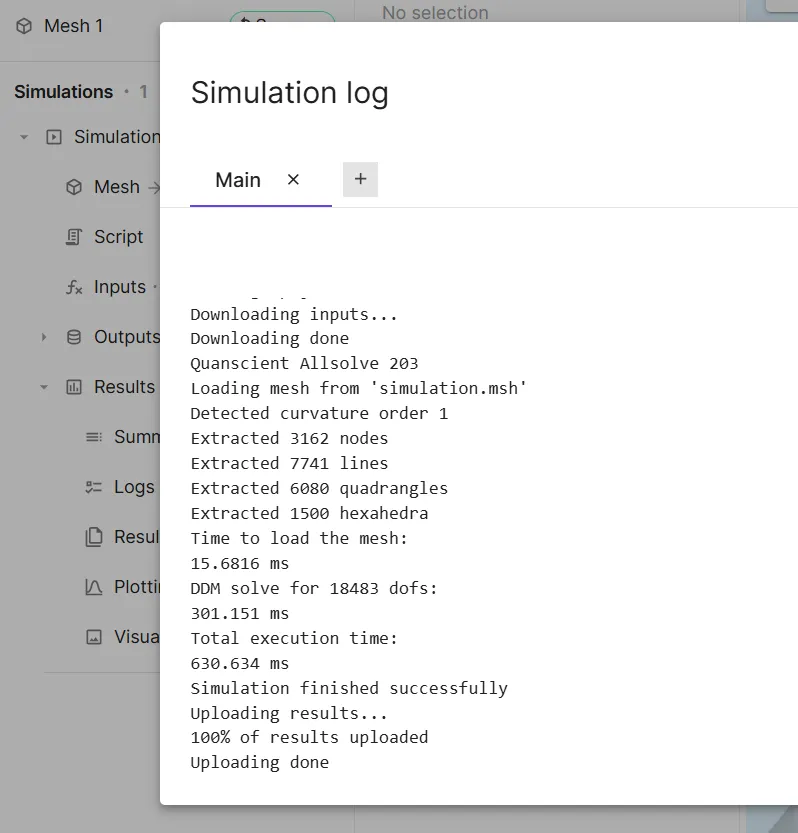

Run the simulation again.

This time the simulation converges within one iteration as seen from the Logs.

Step 9 - See results

Section titled “Step 9 - See results”-

Add a visualization for the

Tfield and render it. The steady-state temperature field distribution becomes visible.

-

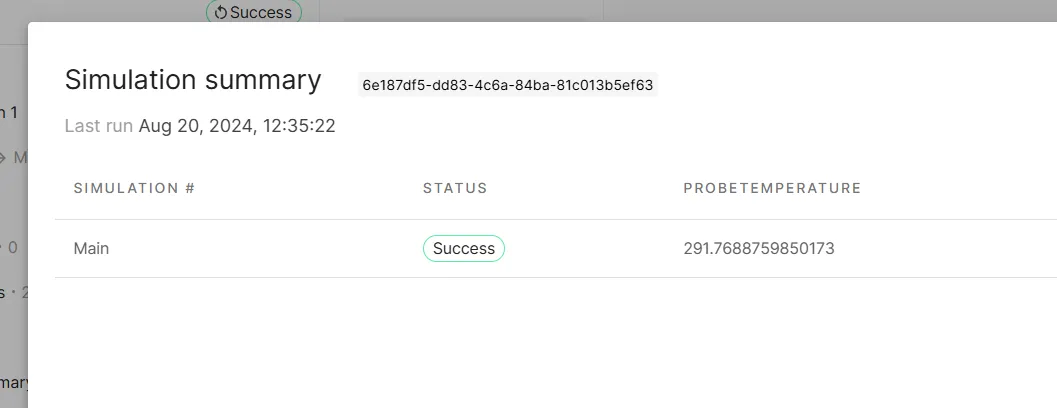

To check the

ProbeTemperaturevalue, check theSummary. Temperature at the probe location(0.3, -0.3, 0.0)m is291.77K, which is very close to the benchmark value1 of291.4K.

Result accuracy scales with mesh density. An even more accurate result would be obtained with a finer mesh.