MUTs 002 - Piezocomposite transducer

In this example case, a piezocomposite ultrasound transducer is simulated. Their main application is in medicine, where they are used for ultrasound imaging and medical therapeutics. Other applications include sonar and non-destructive testing.

The model captures a single element of a 1-3 piezocomposite linear array. The piezocomposite combines a soft PZT with an epoxy filler with a 40% volume fraction. The piezocomposite sits on a backing layer, and utilizes a 1/4 wavelength matching layer for better coupling into the water load. The centre element of the array is driven with a short voltage pulse to allow the wideband behaviour, or impulse response, of the device to be captured. Key outputs are:

- Drive voltage and current

- Pressure in the load

- Electrical impedance

Demo project: Piezocomposite demo V1

Simulation setup guide

Section titled “Simulation setup guide”Here you’ll find a simplified, example case level guide for setting up a piezocomposite transducer simulation in Quanscient Allsolve.

Step 1 - Define variables

Section titled “Step 1 - Define variables”Start out in the Common sidebar by defining variables:

| Name | Description | Expression |

|---|---|---|

| frequency | Frequency [Hz] | 1.25e6 |

| ncycles | Number of cycles | 5 |

| npillars | Number of pillars | 5 |

| thick_comp | Composite thickness [m] | 1e-3 |

| kerf | Cut width [m] | 0.15e-3 |

| pitch | Distance between cuts [m] | 0.4e-3 |

| pillar | Pillar width [m] | pitch-kerf |

| width | Element width [m] | npillars*pitch - kerf |

Step 2 - Build the geometry

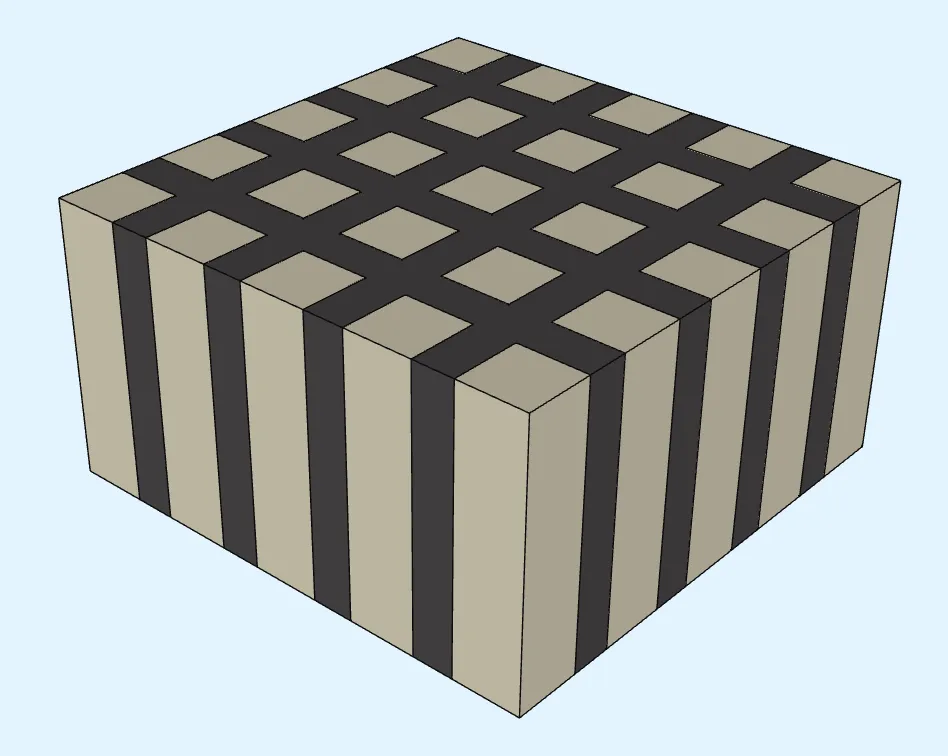

Section titled “Step 2 - Build the geometry”-

Go the

Geometrysection. -

Start building the model geometry by adding Box elements:

Name Element type Center point [m] Size [m] Rotation [deg] pzt Box X: 0X: widthX: 0Y: 0Y: widthY: 0Z: thick_comp/2Z: thick_compZ: 0Name Element type Center point [m] Size [m] Rotation [deg] cut x Box X: 0X: widthX: 0Y: -width/2 + kerf/2 + pillarY: kerfY: 0Z: thick_comp/2Z: thick_compZ: 0Name Element type Center point [m] Size [m] Rotation [deg] cut y Box X: -width/2 + kerf/2 + pillarX: kerfX: 0Y: 0Y: widthY: 0Z: thick_comp/2Z: thick_compZ: 0 -

Use the Translate operation to copy the cuts in X and Y directions:

Name Element type Target Translation [m] Copy Repeat count copy x Translation cut y volume ( 25)X: pitchYes npillars - 2Y: 0Z: 0Name Element type Target Translation [m] Copy Repeat count copy y Translation cut x volume ( 13)X: 0Yes npillars - 2Y: pitchZ: 0 -

Use the Union operation to merge all the multiplied cuts to a single volume:

Name Element type Target combine polymer Union cut volumes ( 13, 25-31) -

Confirm model changes.

Finished geometry:

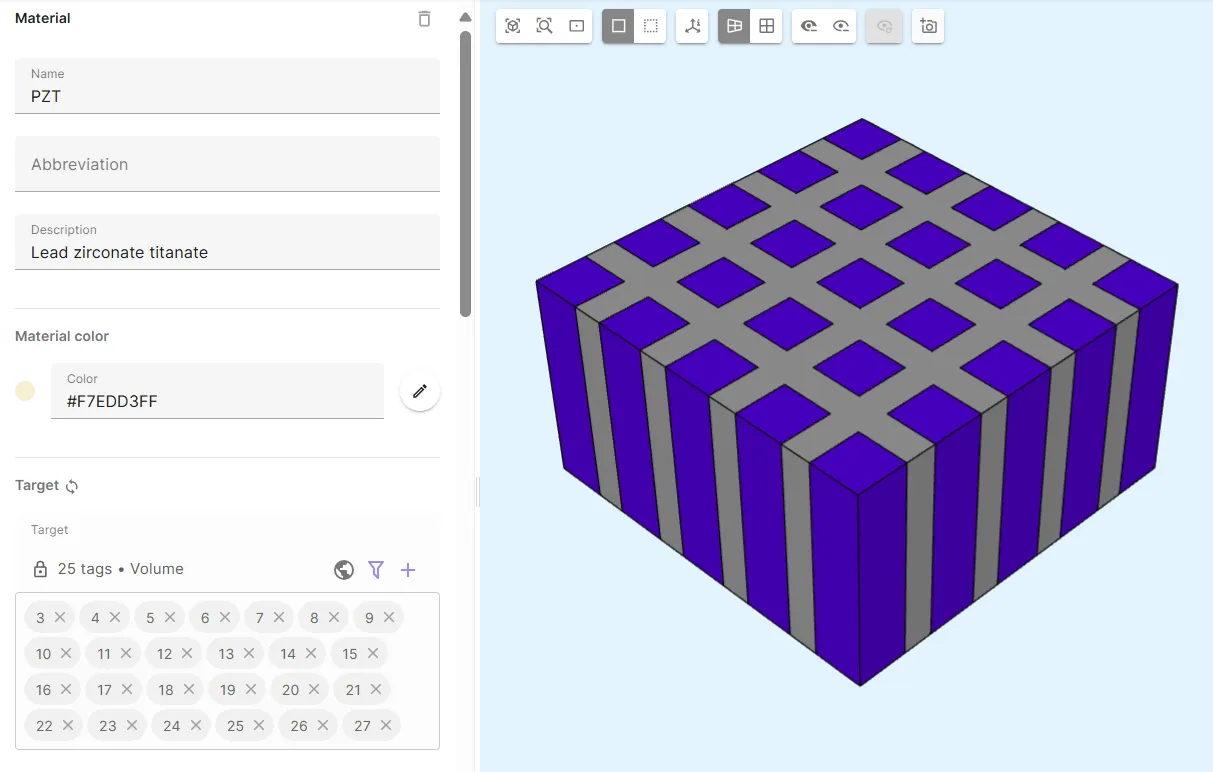

Step 3 - Define the materials

Section titled “Step 3 - Define the materials”Go to the Physics section to define model materials.

Material 1 - PZT

Section titled “Material 1 - PZT”Assign PZT to the piezoelectric pillars.

There are 25 of them in total. To save some clicks:

Select allvolumes- Remove the epoxy filler volume (

2) from your selection.

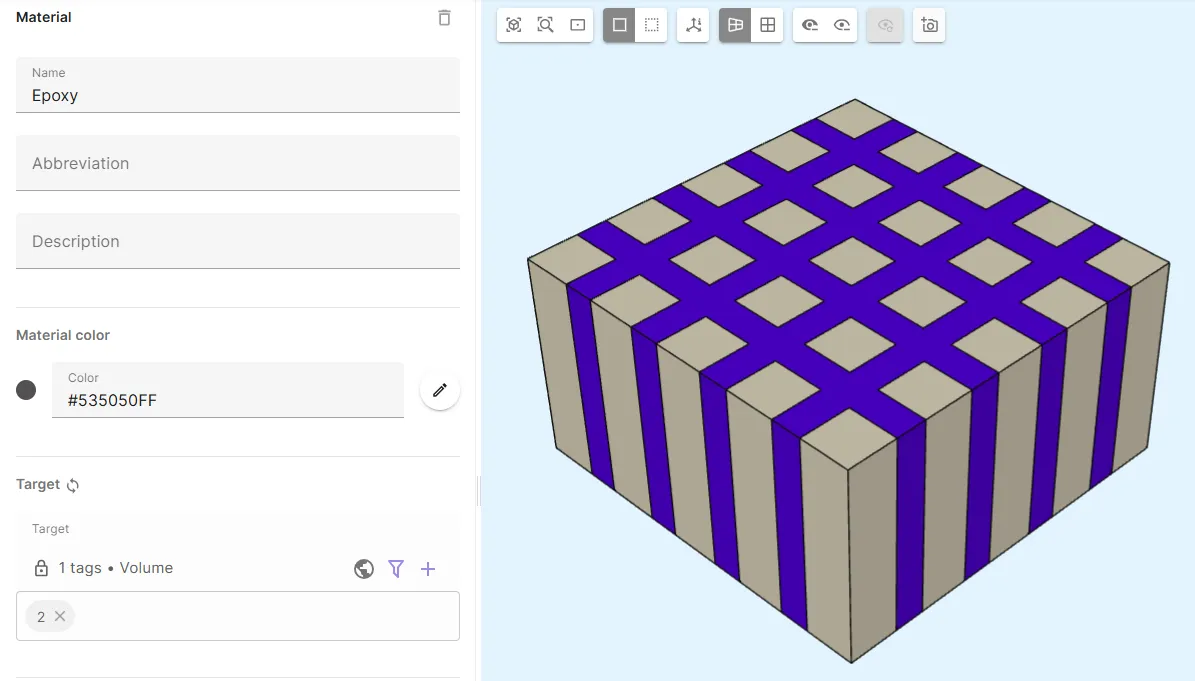

Material 2 - Epoxy

Section titled “Material 2 - Epoxy”Create a new material for the epoxy filler:

| Material | Target |

|---|---|

| Epoxy | Polymer filler volume (2) |

Define properties for Epoxy:

| Property | Value | Units |

|---|---|---|

| Density | 1134 | |

| Elasticity matrix | Poisson’s ratio: 0.37 | - |

Young’s modulus: 3.831e9 | ||

| Electric permittivity | 4*epsilon0 |

Step 4 - Define the physics

Section titled “Step 4 - Define the physics”Go to the Physics section.

The Elastic waves and Electrostatics physics are required for this example.

Add both of them before moving on to define interactions.

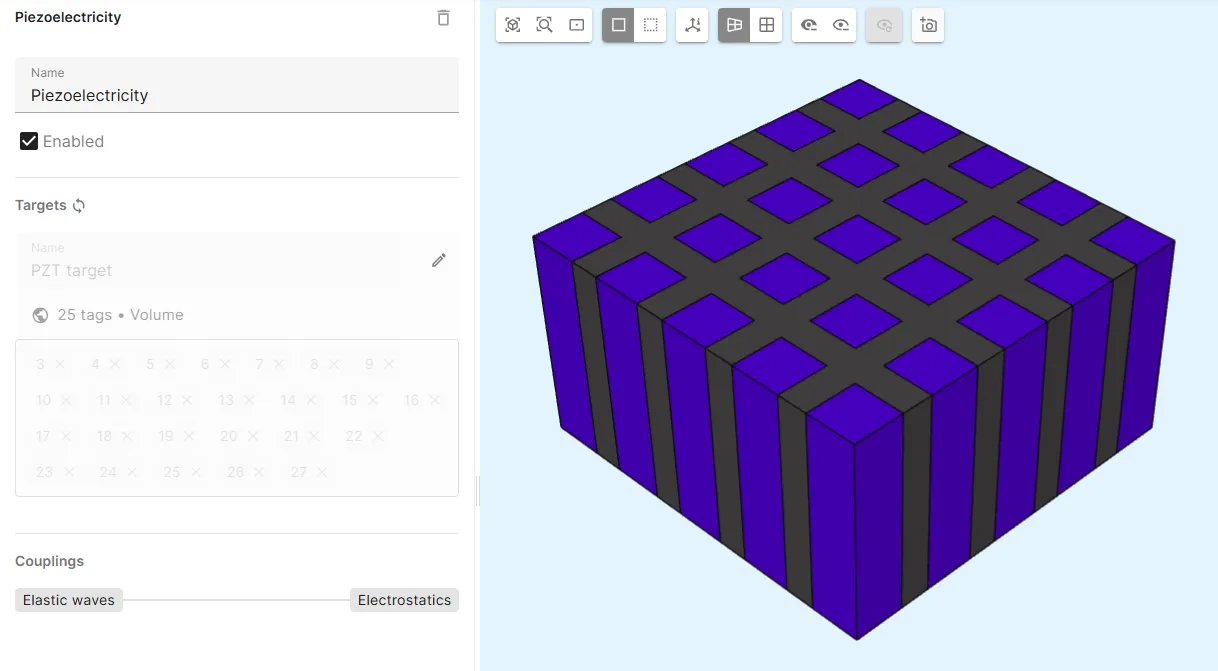

Physics 1 - Elastic waves

Section titled “Physics 1 - Elastic waves”- Let elastic waves target default to the whole geometry.

- Add the Elastic waves - Electrostatics coupling

Piezoelectricity.- Select the

PZT targetshared region as target.

- Select the

Physics 2 - Electrostatics

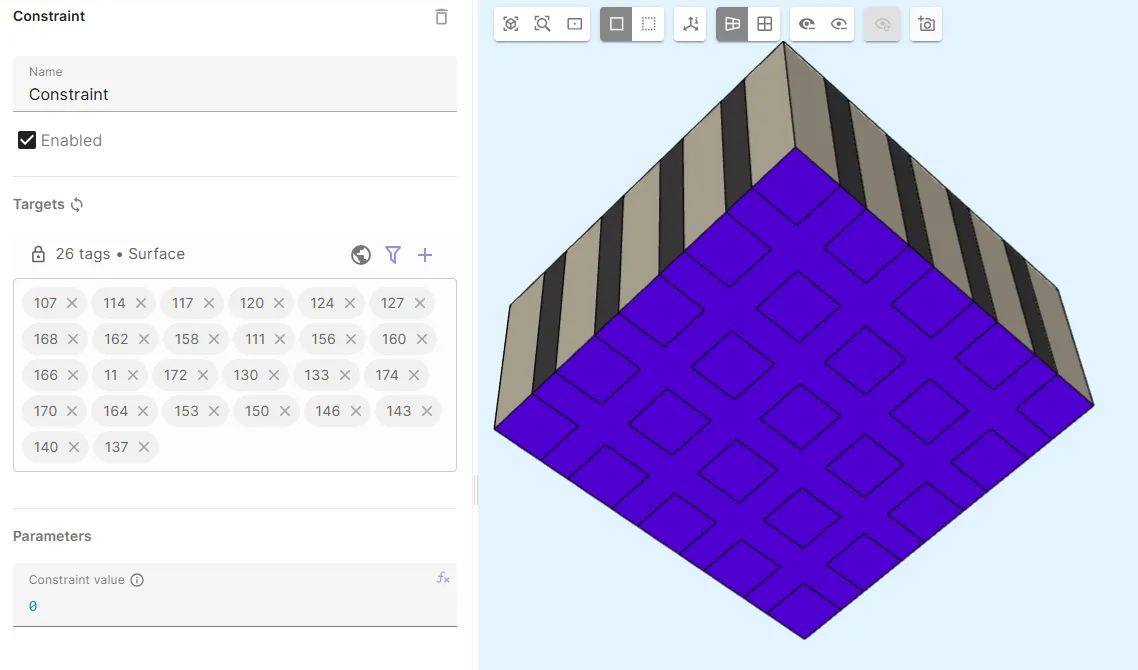

Section titled “Physics 2 - Electrostatics”-

Let Electrostatics target default to the whole geometry.

-

Add a

Constraintinteraction which acts as a ground on the bottom surface:Interaction Target Constraint value ConstraintBottom surface of the element 0

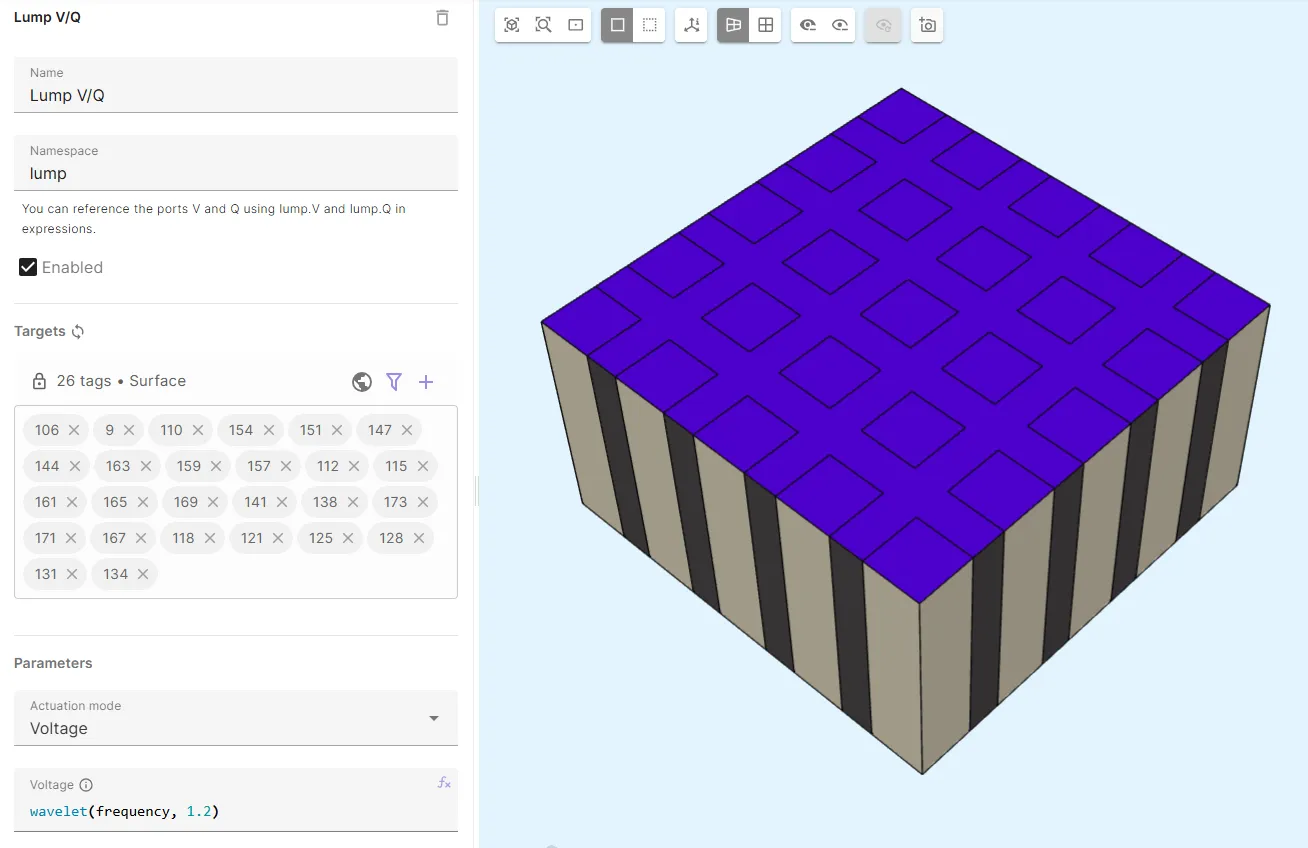

-

Add a

Lump V/Qinteraction which drives a voltage on the top surface:Interaction Target Voltage Lump V/QTop surface of the element wavelet(frequency, 1.2)

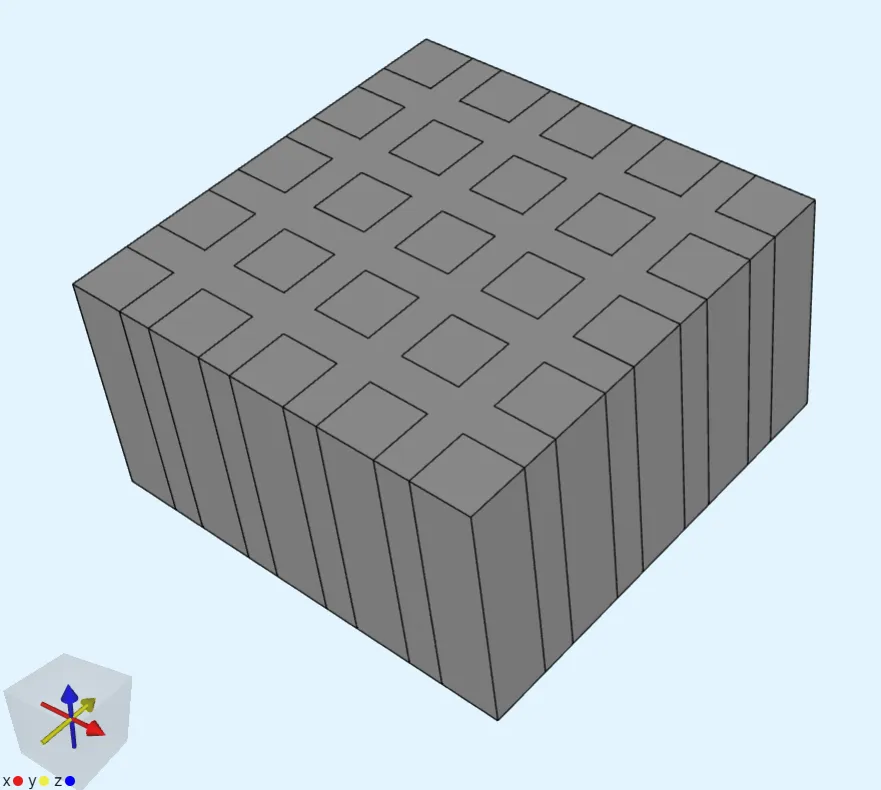

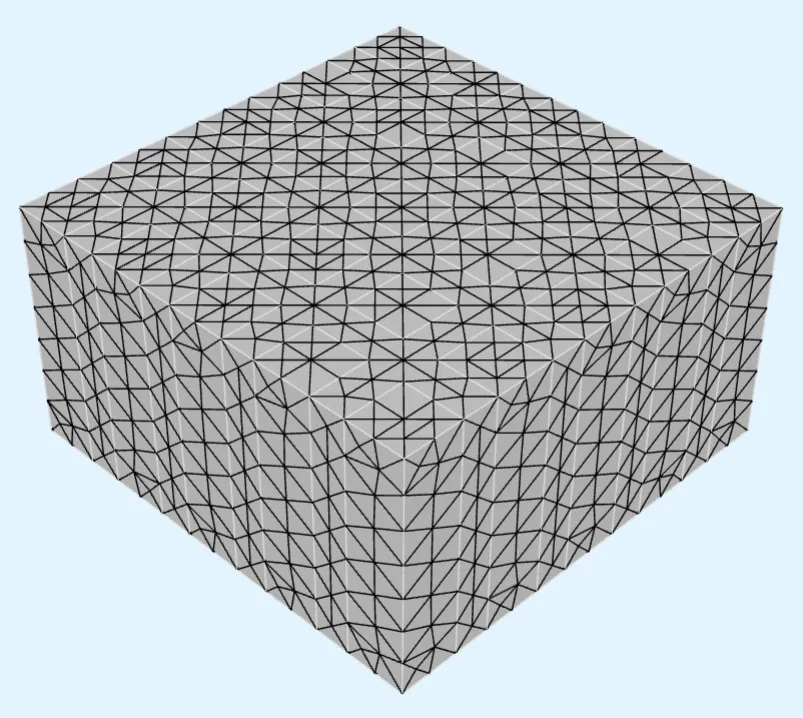

Step 5 - Generate the mesh

Section titled “Step 5 - Generate the mesh”Go to the Simulations section and create a new mesh:

- Set Mesh quality to

Expert settings. - Set Used mesher to

Basic. - Set Max size to

kerf. - Apply settings and mesh.

- Check the preview:

Step 6 - Simulate

Section titled “Step 6 - Simulate”In the Simulations section, create a new simulation:

-

Set Analysis type to

Transient. -

Select timestepping options:

Timestep algorithm Start time [s] End time [s] Timestep size [s] Generalized alpha0ncycles/frequency1/frequency/20 -

Select the mesh.

-

Add Outputs:

Output type Name Output expression Skin only Field Displacement field u uYes Custom value Voltage lump.VCustom value Current dt(lump.Q)

Your simulation is now ready to run.

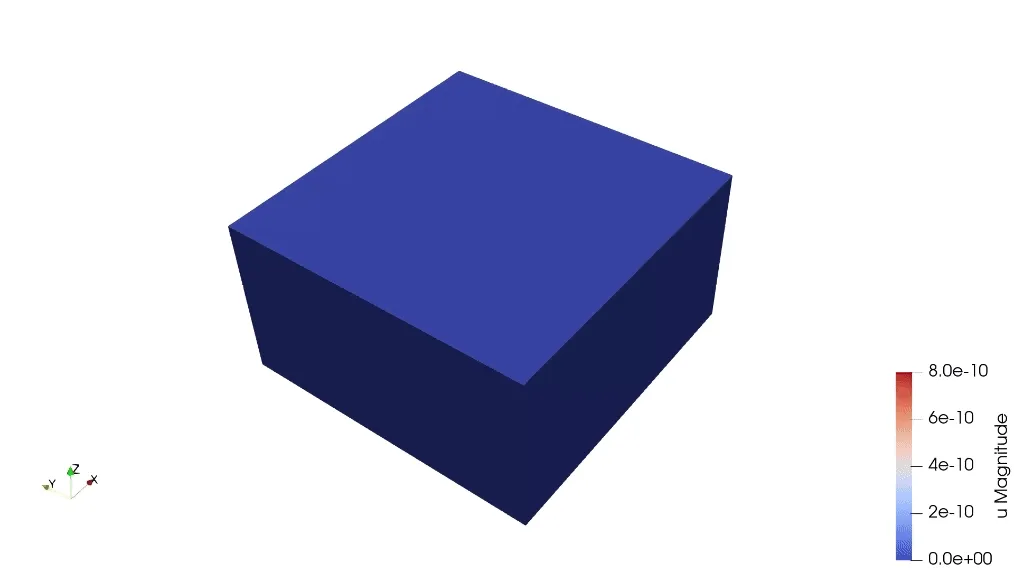

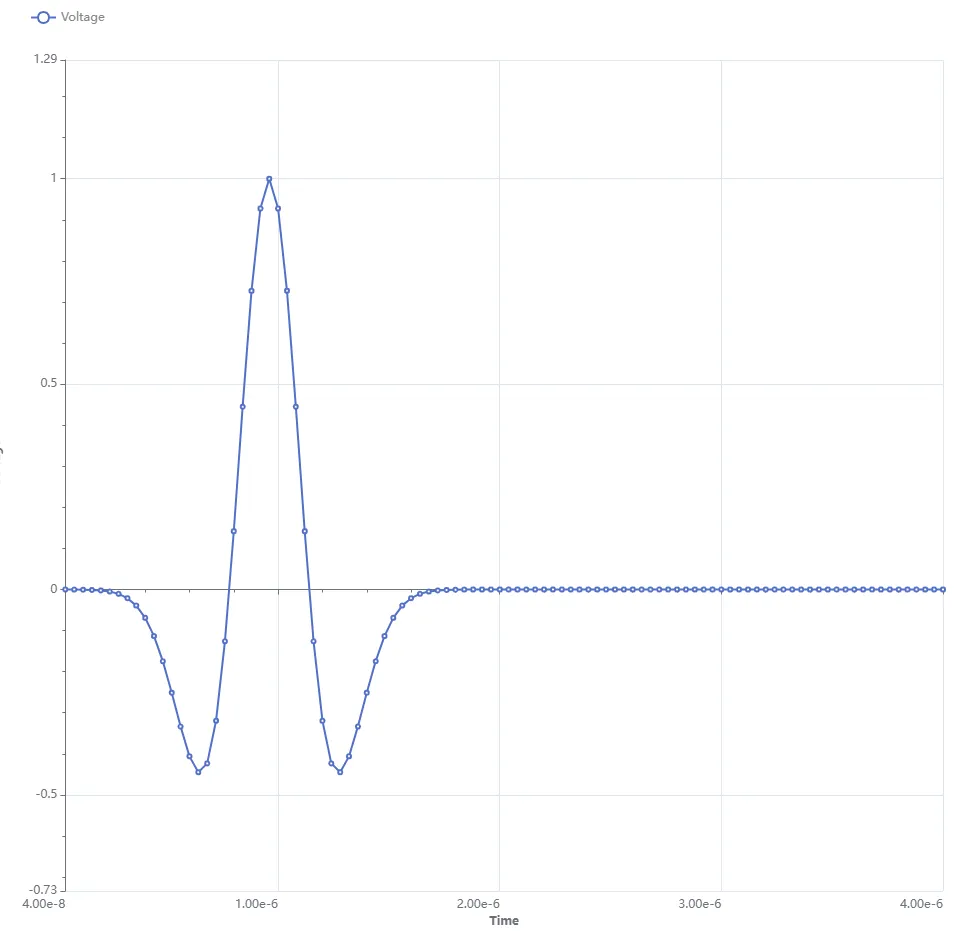

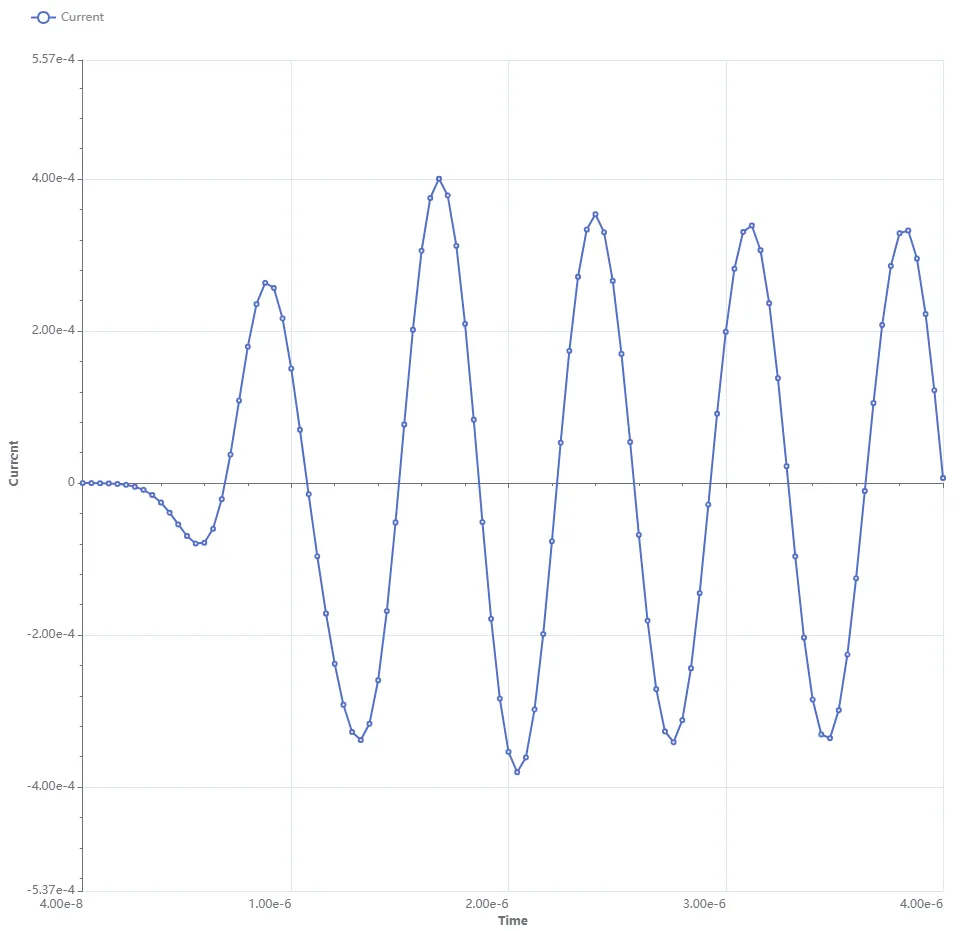

Step 7 - Results

Section titled “Step 7 - Results”In the Simulations section, you can add plots to see value output results and visualizations to see field output results.

-

Voltage:

-

Current:

-

Displacement field: