SC 002 - Twisted superconductor AC Loss

In this tutorial, AC loss in a high-temperature superconducting (HTS) wire is simulated using the H-φ formulation.

Model definition

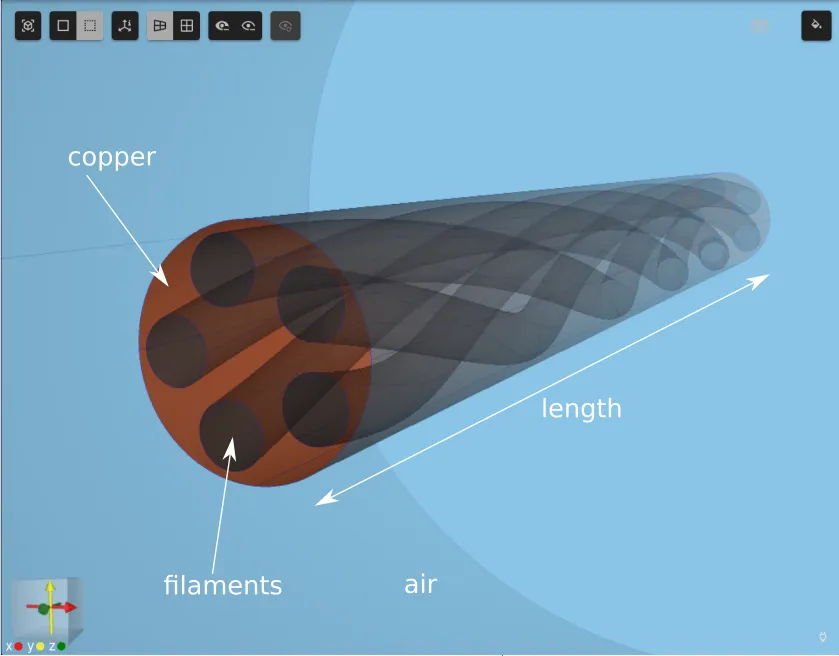

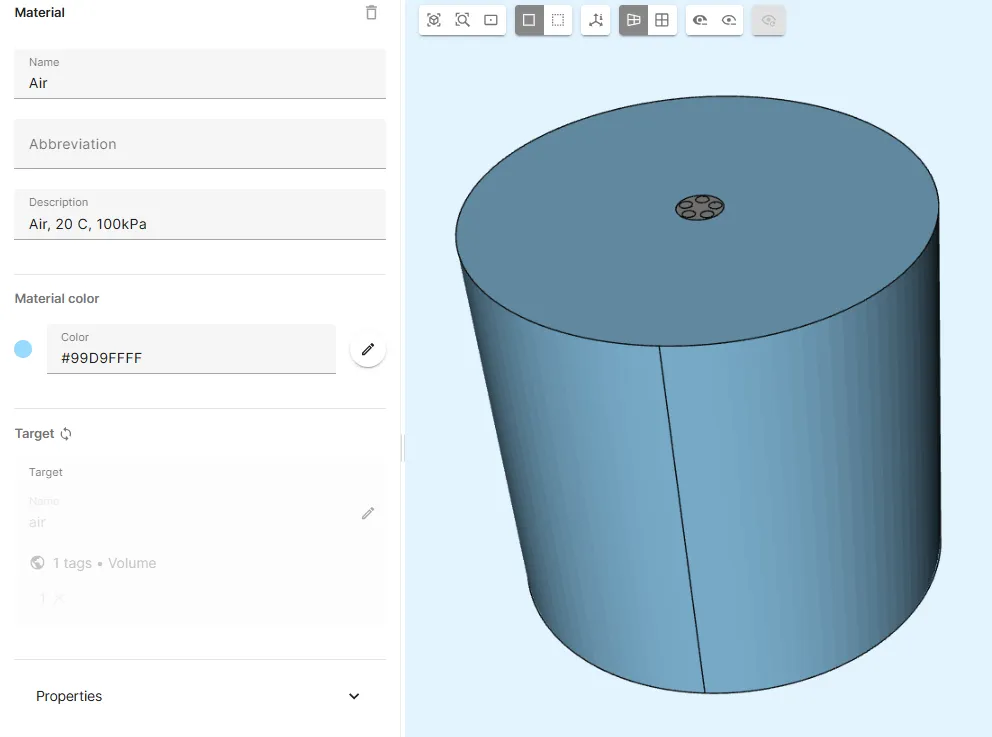

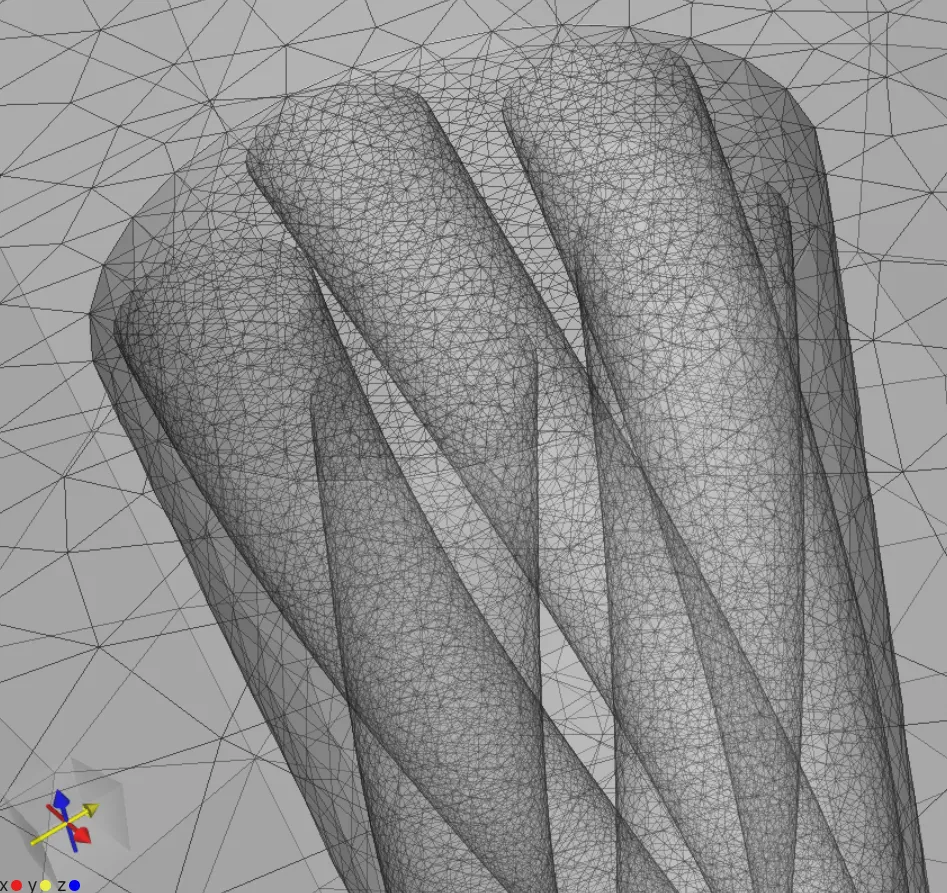

Section titled “Model definition”The wire consists of twisted superconducting filaments embedded into a copper matrix. The whole modelling domain with an air cylinder around the wire is illustrated below.

| Element | Dimension |

|---|---|

| Air cylinder diameter | 10 mm |

| Copper cylinder diameter | 535 μm |

| Filament diameter | 350 μm |

| Domain length | 10 mm |

Output results

Section titled “Output results”- Joule losses as a function of time in the copper and the superconducting filament regions. The losses over the volume of interest can be computed as

Material Data

Section titled “Material Data”Magnetic permeability, :

- all domains:

Electric resistivity, :

- Copper:

- Superconducting filaments:

-

- Critical electric field strength,

- Exponent,

- Critical electric current,

- Total cross-section are of superconducting filaments,

- Critical electric current density,

-

Source

Section titled “Source”The problem is sourced by applying a total current of

where the frequency is .

Step-by-step guide

Section titled “Step-by-step guide”Here you’ll find a detailed step-by-step tutorial on how to simulate AC loss in a twisted filament HTS wire Quanscient Allsolve.

Step 1 - Import the geometry

Section titled “Step 1 - Import the geometry”-

Start with a new project and name it as

SC twisted filament AC loss -

Import the geometry as a

.stepfile with default import options.File download link: twisted-superconductor.step

-

Confirm model changes.

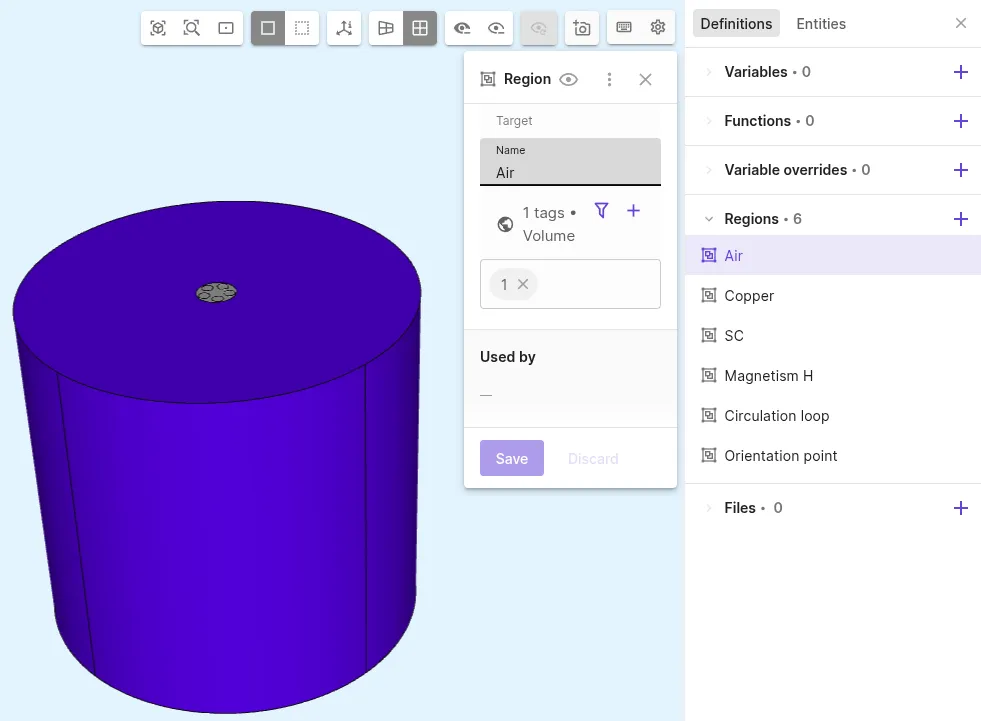

Step 2 - Define shared regions

Section titled “Step 2 - Define shared regions”-

Go to the

Commonsidebar. -

Define a shared region for air:

Region name Region type Target airVolume Air cylinder

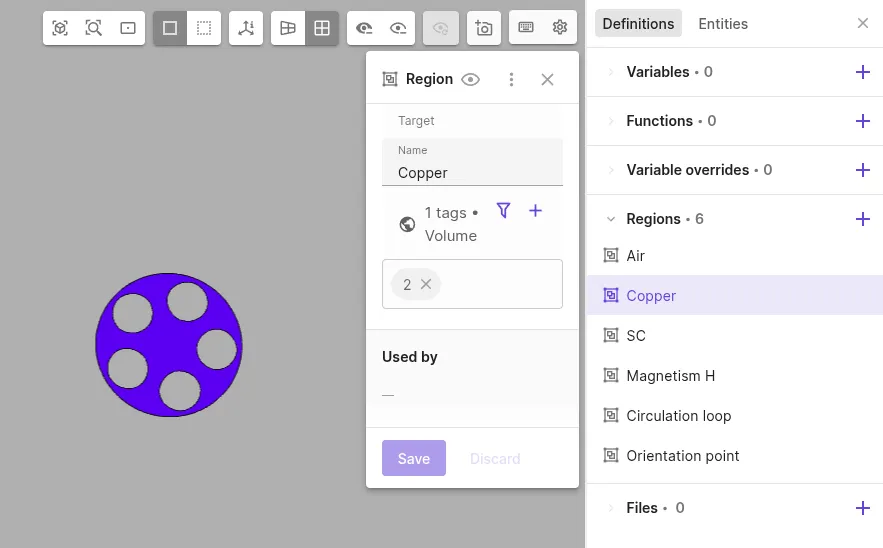

-

Define a shared region for copper:

Region name Region type Target copperVolume Copper matrix

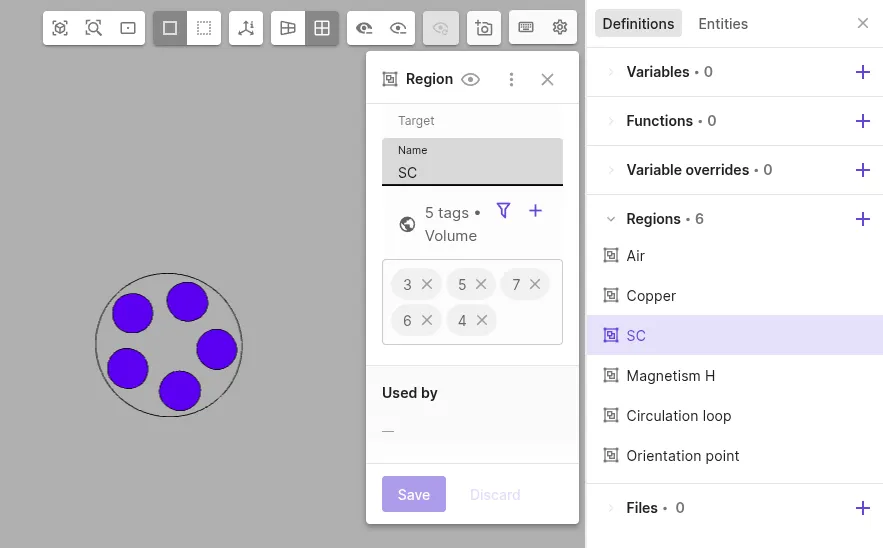

-

Define a shared region for the superconducting filaments:

Region name Region type Target scVolume SC filaments

Step 3 - Define materials

Section titled “Step 3 - Define materials”-

Assign the Air material to the

airshared region:

-

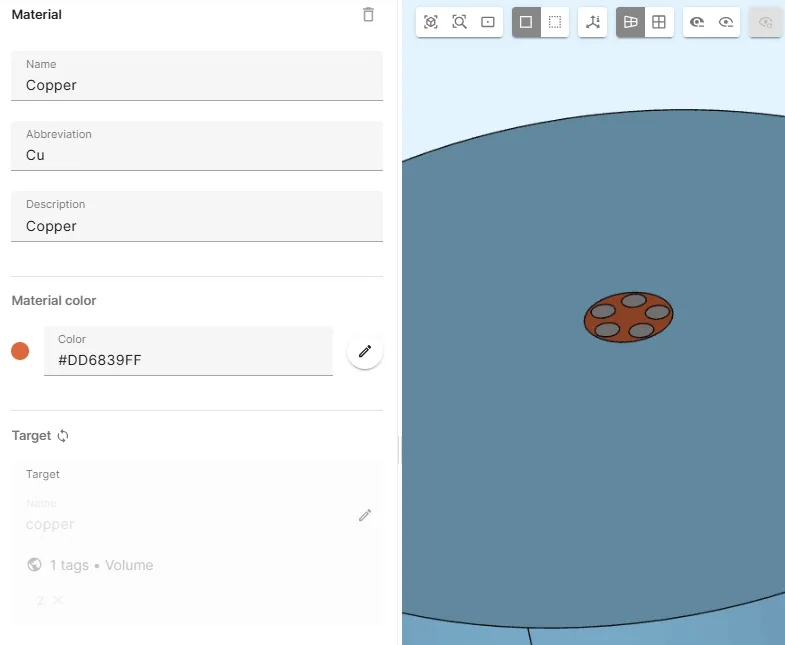

Assign the Copper material to the

coppershared region:

-

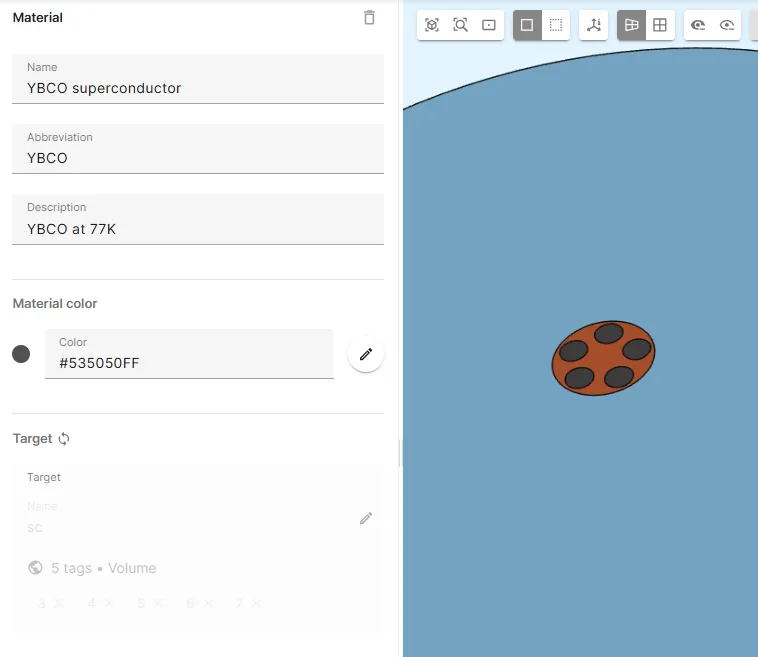

Assign the YBCO superconductor material to the

scshared region:

Step 4 - Define variables

Section titled “Step 4 - Define variables”-

Define new variables:

Name Description Expression f Frequency [Hz] 50YBCO_Ic Critical current [A] 100YBCO_Asc Filament cross-section area [m^2] 3.4541e-7Iop Operating current [A] 0.8 * YBCO_Ic * sin(2 * pi * f * t) -

Modify existing variables:

Name Modified expression YBCO_Jc YBCO_Ic / YBCO_AscYBCO_n 30

Step 5 - Define physics and apply the current source

Section titled “Step 5 - Define physics and apply the current source”-

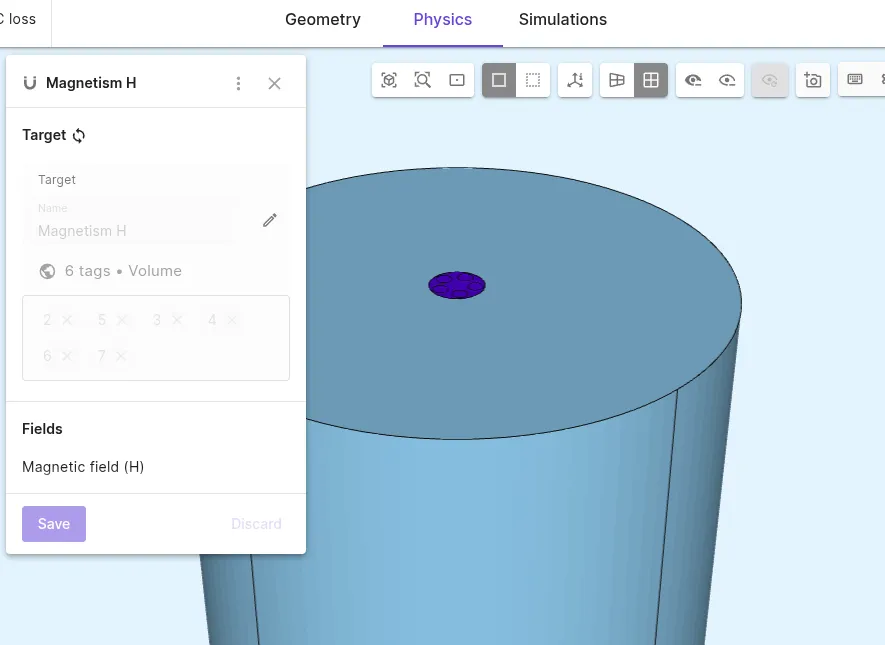

Go to the

Physicssection. -

Add the

Magnetism Hphysics:Physics Target Magnetism H Copper matrix and SC filaments

-

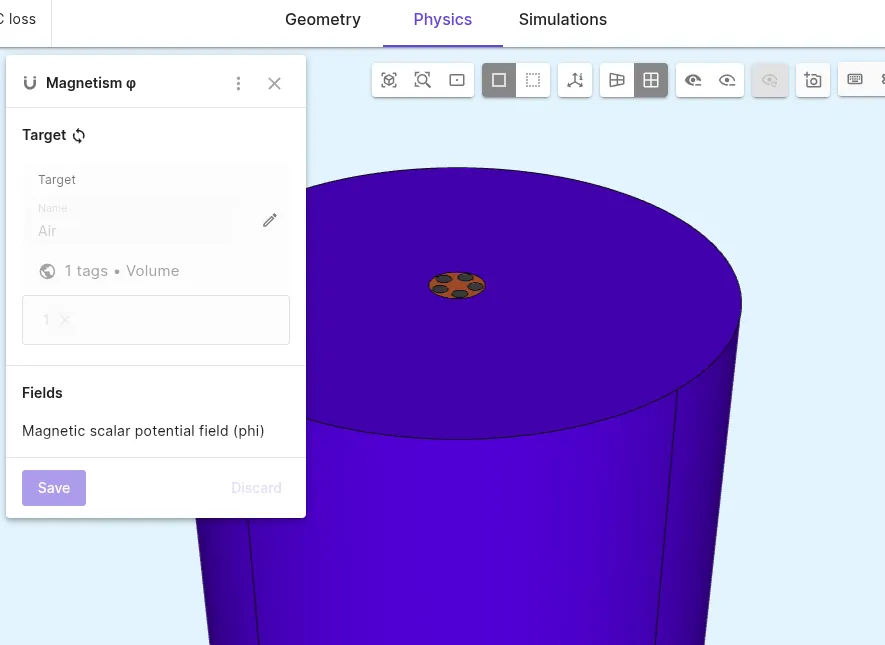

Add the

Magnetism φphysics:Physics Target Magnetism φ Air cylinder ( airshared region)

-

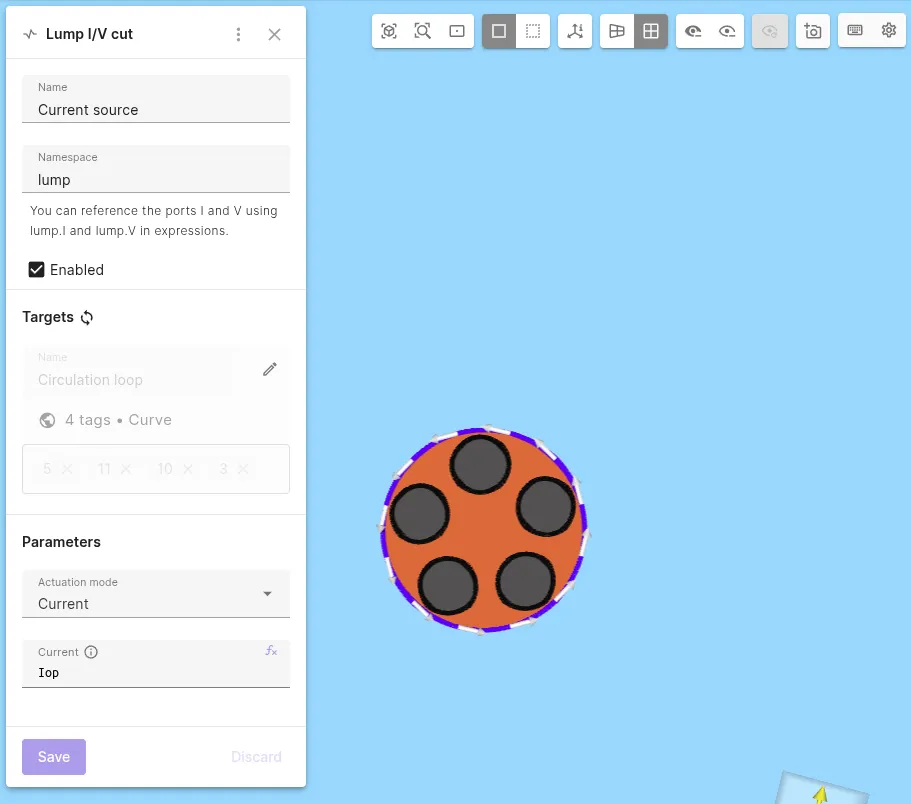

Add a

Lump I/V cutinteraction to Magnetism φ.Interaction name Interaction type Target Value Current source Lump I/V cuta counter-clockwise loop at the top edge of the copper matrix Iop

-

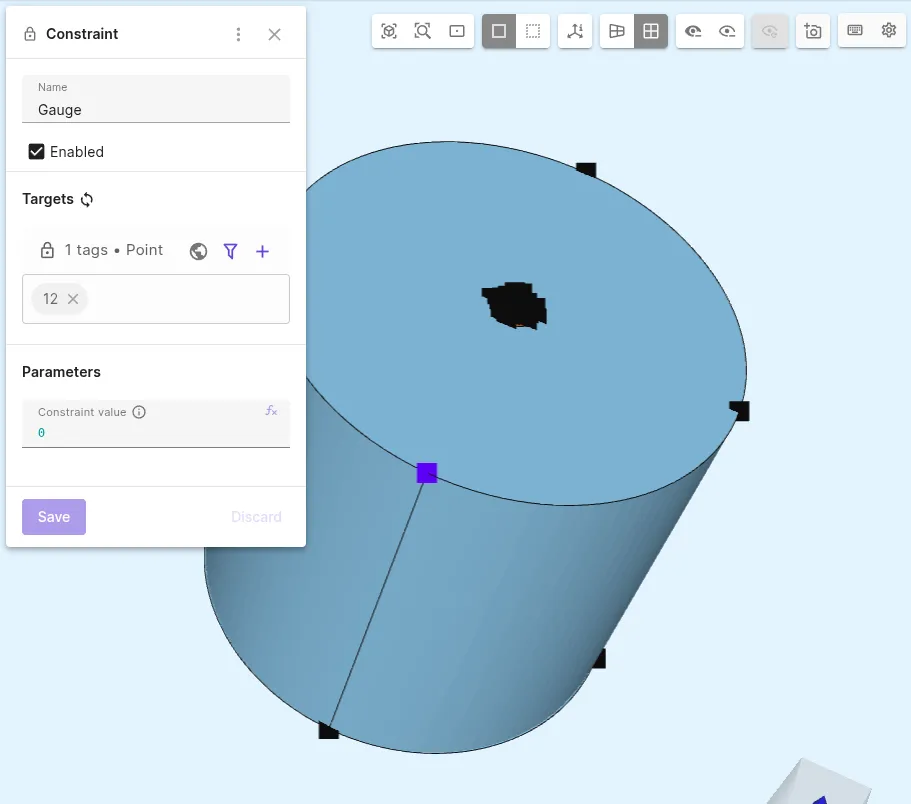

Add a

Constraintinteraction to Magnetism φ:Interaction name Interaction type Target Value Gauge Constrainta point at the external boundary of the air domain 0

-

Add the

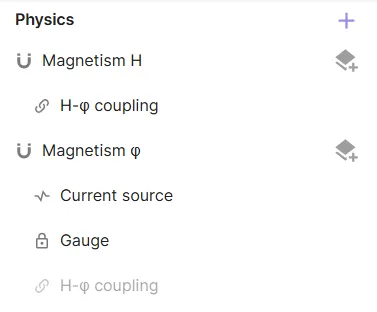

H-φ couplinginteraction to Magnetism H. -

Before moving on, check that your physics tree matches the one below:

Step 6 - Generate a mesh

Section titled “Step 6 - Generate a mesh”-

Go to the

Simulationssection. -

Add a new mesh.

-

Set Mesh quality to

Expert settings. -

Set Used mesher to

Basic. -

Set Curvature enhancement to

25. -

Generate the mesh and check the preview.

Step 7 - Select simulation settings

Section titled “Step 7 - Select simulation settings”-

Add a new simulation.

-

Set Analysis type to

Transient. -

Select Transient settings:

Timestep algorithm Start time [s] End time [s] Timestep size [s] Implicit Euler 00.010.0001 -

Set Solver mode to

Iterative solver. -

Set Node count to

50. -

Select

Mesh 1as the mesh for your simulation. -

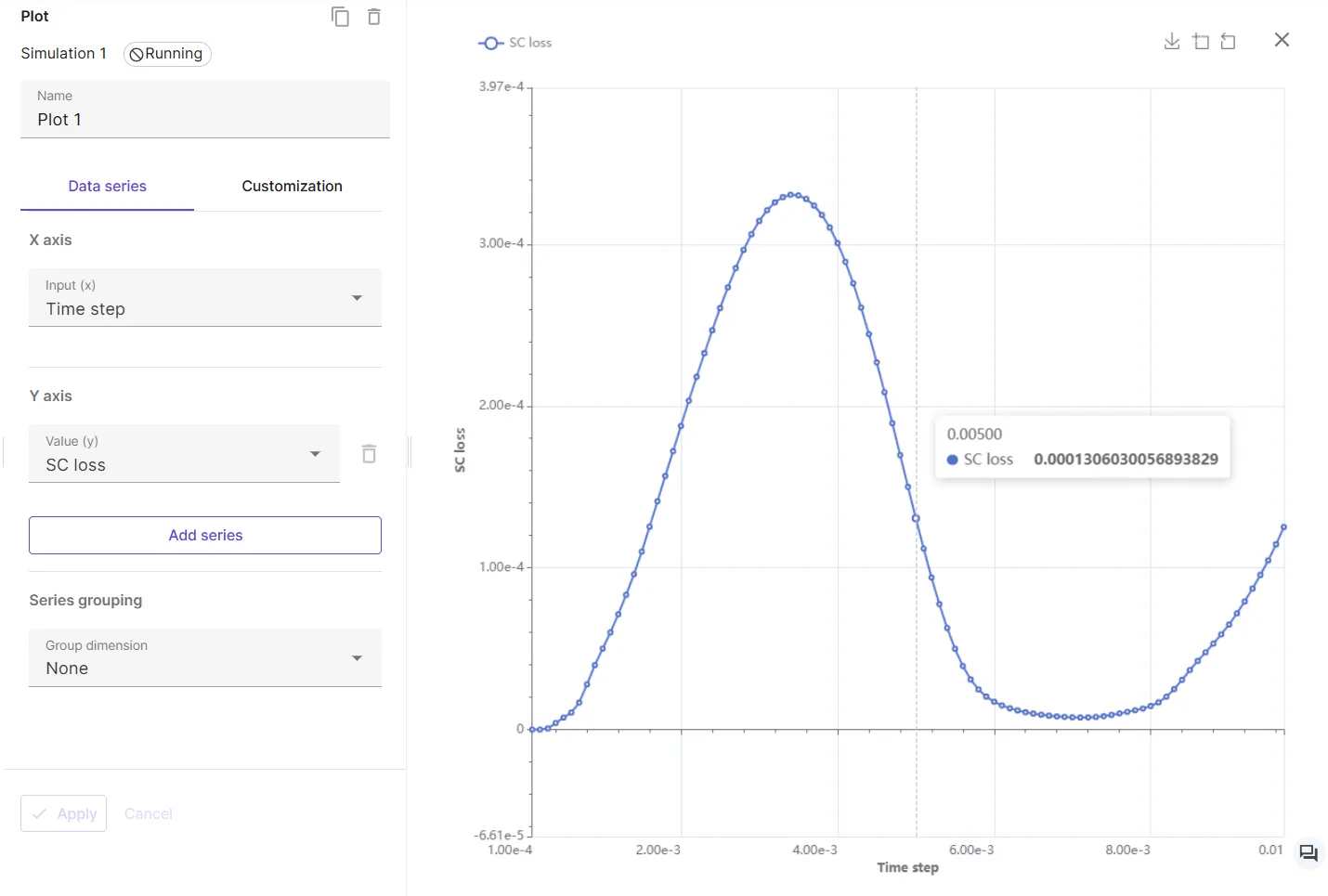

Define custom value outputs for computing Joule losses in the filaments and copper:

Output name Output type Output expression SC loss Custom value output integrate(reg.sc, transpose(E) * j, 4)Cu loss Custom value output integrate(reg.copper, transpose(E) * j, 4) -

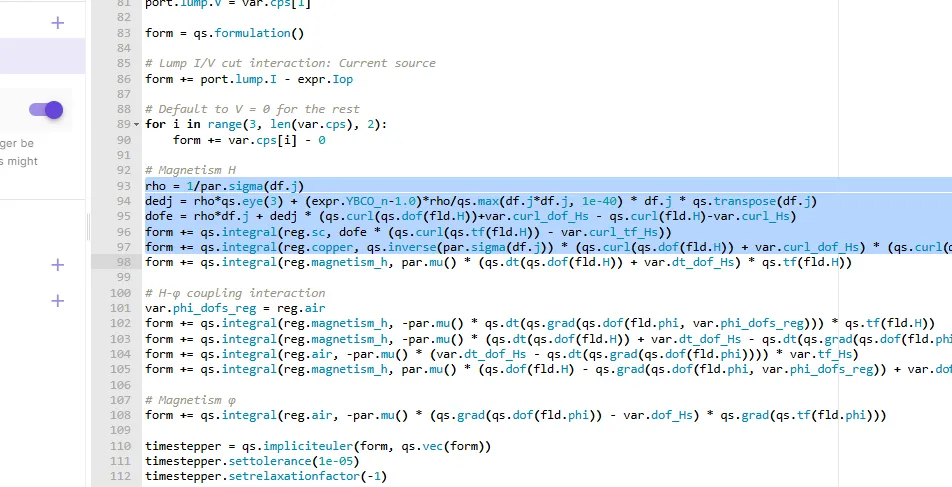

Open the Script for your simulation.

-

Enable

Scripting mode. -

Replace the first autogenerated line under

# Magnetism Hwith the following Newton-linearization [4]:rho = 1/par.sigma(df.j)dedj = rho*qs.eye(3) + (expr.YBCO_n-1.0)*rho/qs.max(df.j*df.j, 1e-40) * df.j * qs.transpose(df.j)dofe = rho*df.j + dedj * (qs.curl(qs.dof(fld.H))+var.curl_dof_Hs - qs.curl(fld.H)-var.curl_Hs)form += qs.integral(reg.sc, dofe * (qs.curl(qs.tf(fld.H)) - var.curl_tf_Hs))form += qs.integral(reg.copper, qs.inverse(par.sigma(df.j)) * (qs.curl(qs.dof(fld.H)) + var.curl_dof_Hs) * (qs.curl(qs.tf(fld.H)) - var.curl_tf_Hs))

Step 8 - Run the simulation and see results

Section titled “Step 8 - Run the simulation and see results”-

Run the simulation.

-

To follow the simulation progress, open

Logs. -

The SC and Cu loss results can be seen in

Plotting, even while the simulation is running:

References

Section titled “References”[1] H-φ Formulation in Sparselizard Combined With Domain Decomposition Methods for Modeling Superconducting Tapes, Stacks, and Twisted Wires. https://doi.org/10.1109/TASC.2023.3240389

[2] Allsolve demo project of Superconductor AC losses. https://allsolve.quanscient.com/#/projects/demo/8fed82d1-5bf0-4c02-835b-94e65a60f847

[3] Youtube tutorial of Superconductor AC losses. https://youtu.be/B9QZZ5y7RpQ

[4] Newton Linearization. https://en.wikiversity.org/wiki/Nonlinear_finite_elements/Newton_method_for_finite_elements