HB 002 - Backbone curve of a clamped-clamped beam

Beams are fundamental structural elements used in a wide range of applications, from bridges and aircraft to microelectronics. However, beams are susceptible to vibrations, which can lead to fatigue, instability, and potential failure. Therefore, understanding beam vibration behavior is essential for engineers across various disciplines.

This simulation example case investigates the multiharmonic vibration characteristics of a thin metal beam clamped at both ends. This “clamped-clamped beam” model provides insights into how boundary conditions influence vibrational behavior.

The model consists of a simple, thin beam made up of metal-like custom material. As simulation output, we take the maximum displacement of the beams harmonic displacement (vibration). When plotted, the displacement a so-called “backbone curve”. The setup is detailed in the paper Parallel harmonic balance method for analysis of nonlinear dynamical systems1.

Demo project: 2(https://allsolve.quanscient.com/#/projects/428c622d-977f-4e82-a027-a51d5a489875)

Step 1 - Build the geometry

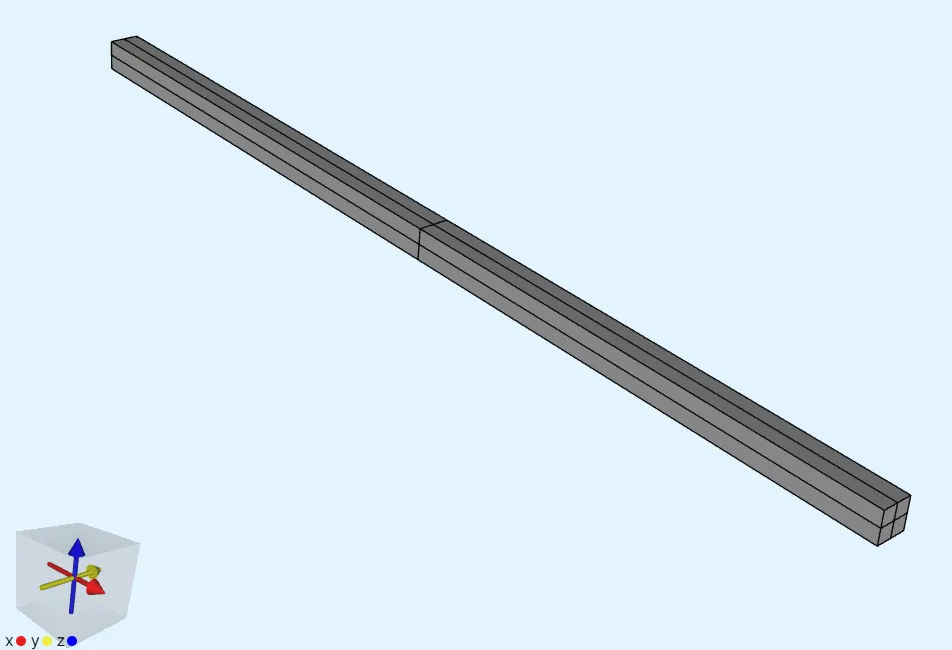

Section titled “Step 1 - Build the geometry”In the Model section, build boxes to make the beam geometry:

| Name | Element type | Center point [m] | Size [m] | Rotation [deg] |

|---|---|---|---|---|

| Beam | Box | X: 0 | X: 1 | X: 0 |

Y: 0 | Y: 0.03 | Y: 0 | ||

Z: 0 | Z: 0.03 | Z: 0 |

| Name | Element type | Center point [m] | Size [m] | Rotation [deg] |

|---|---|---|---|---|

| Beam half X | Box | X: 0.25 | X: 0.5 | X: 0 |

Y: 0 | Y: 0.03 | Y: 0 | ||

Z: 0 | Z: 0.03 | Z: 0 |

| Name | Element type | Center point [m] | Size [m] | Rotation [deg] |

|---|---|---|---|---|

| Beam half Y | Box | X: 0 | X: 1 | X: 0 |

Y: 0.0075 | Y: 0.015 | Y: 0 | ||

Z: 0 | Z: 0.03 | Z: 0 |

| Name | Element type | Center point [m] | Size [m] | Rotation [deg] |

|---|---|---|---|---|

| Beam half Z | Box | X: 0 | X: 1 | X: 0 |

Y: 0 | Y: 0.03 | Y: 0 | ||

Z: 0.0075 | Z: 0.015 | Z: 0 |

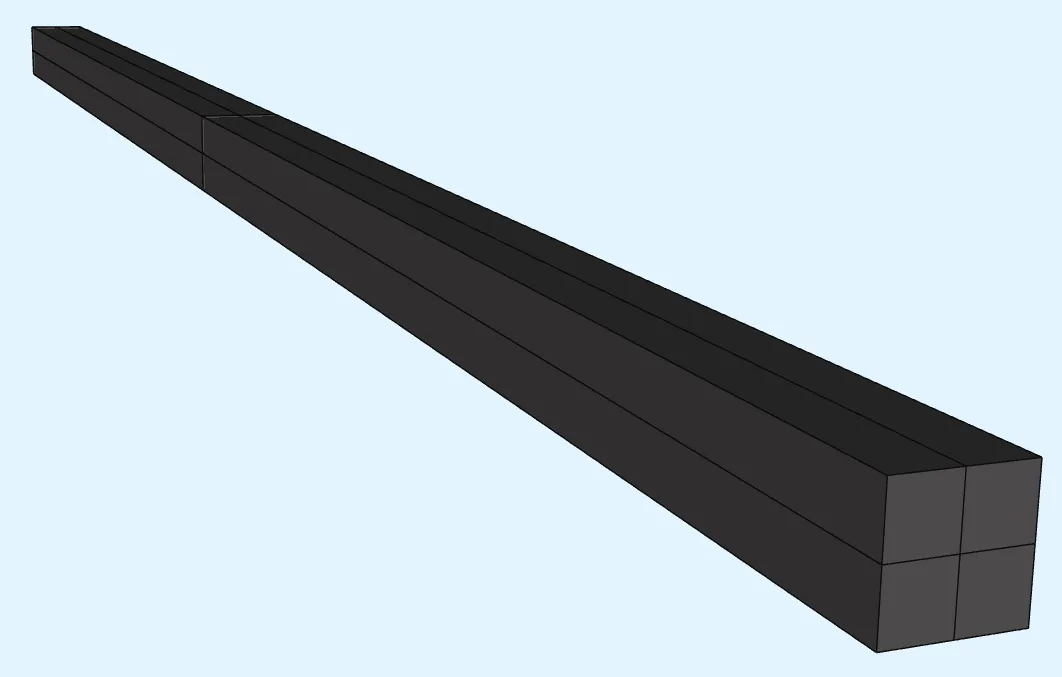

Finished geometry:

Confirm model changes before moving on.

Step 2 - Define variables and materials

Section titled “Step 2 - Define variables and materials”Go to the Common sidebar.

- Define a variable:

| Name | Description | Expression |

|---|---|---|

| freq | Fundamental frequency for multiharmonic simulation [Hz] | 162.5 |

Go to Physics section

- Create a custom material for the beam:

Name

- Material from paper

Target

- All volumes

1-8- Add the target as a shared region.

Properties

- Add

Density- Set value to

7800[kg / m^3]

- Set value to

- Add

Elasticity matrix- Set Poisson’s ratio to

0.3 - Set Young’s modulus to

210e9[Pa]

- Set Poisson’s ratio to

Step 3 - Define the physics

Section titled “Step 3 - Define the physics”For this example, only Solid mechanics is required.

Add it and define interactions:

- Let solid mechanics target default to all volumes.

- Add

Clamp.- As target, select end surfaces of the beam in positive and negative X-planes (

1, 7, 12, 19, 22, 29, 33, 36).

- As target, select end surfaces of the beam in positive and negative X-planes (

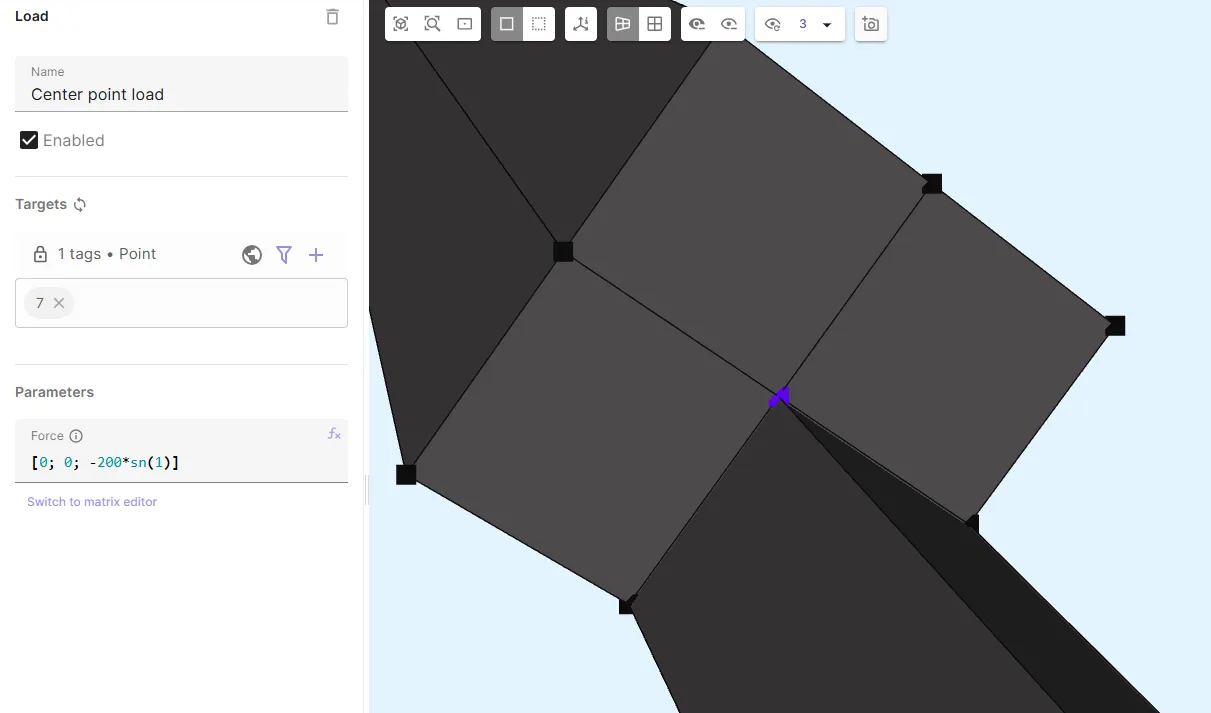

- Add Load and name it as

Center point load.

- As target, select the middle-most point of the beam inside the volume (

7). - Set Force to

[0; 0; -200*sn(1)].

- Add

Geometric nonlinearity. - Add

Proportional dampingto all volumes. Use Rayleigh mass damping only, withAlpha = 3. Neglect stiffness-proportional damping by settingBeta = 0.

Step 4 - Generate the mesh

Section titled “Step 4 - Generate the mesh”Go to the Simulations section.

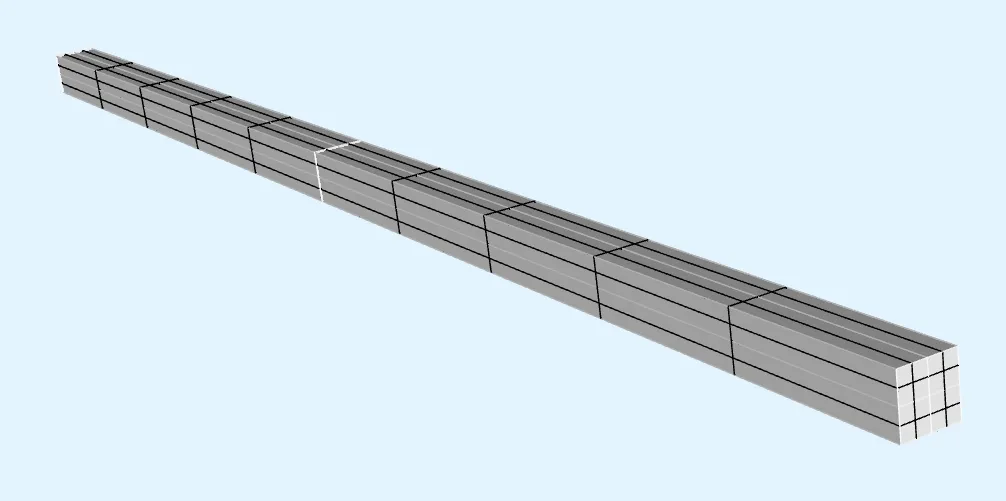

In this example, the geometry is meshed via Transfinite meshing.

- Create a new mesh.

- Set Mesh quality to

Expert settings. - Set Used mesher to

Basic.

- Set Mesh quality to

- Create a transfinite entity for each of the 8 volumes in the model.

- Before defining segment counts for the entities, apply mesh settings to save your work so far.

- For each transfinite entity, choose segment counts so that the long sides are divided into 5 segments, and the short sides into 2 segments.

- Apply settings and mesh.

Step 5 - Simulate

Section titled “Step 5 - Simulate”In the Simulations section, create a new simulation:

-

Analysis type

Multiharmonic

-

Fundamental frequency

freq

-

Harmonics

1, 2, 3

-

Solver mode

Direct solver

-

Mesh

- Select the mesh you created in Step 4.

-

Scripting

- The backbone curve can be computed using either the u-strategy or the f-strategy. Replace your script with the version below, which applies the u-strategy.

var = Variables()mesh = Mesh()fld = Fields()

# Load the meshmesh.mesh = qs.mesh()mesh.mesh.setphysicalregions(*reg.get_region_data())mesh.skin = reg.get_next_free()mesh.mesh.selectskin(mesh.skin)mesh.mesh.partition()mesh.mesh.load("gmsh:simulation.msh", mesh.skin, 1, 1)

# Displacement fieldfld.u = qs.field("h1xyz", [1, 2, 3])fld.u.setorder(reg.all, 2)

# Clamp interactionfld.u.setconstraint(reg.clamp_target)

maxuf2 = qs.sqrt(fld.u.harmonic(2)*fld.u.harmonic(2) + fld.u.harmonic(3)*fld.u.harmonic(3))

# Driving frequency loop with field solution from previous iteration as initial guess:freqmin = 158.0freqmax = 178.0freq = freqmaxdir = -1step = 0.25arcindex = 0nfft = 6

while True:

qs.printonrank(0, "Solving for frequency " + str(freq) + " with direction " + str(dir))

qs.setfundamentalfrequency(freq)

form = qs.formulation()

# Solid mechanics form += qs.integral(reg.all, nfft, qs.predefinedelasticity(qs.dof(fld.u), qs.tf(fld.u), fld.u, par.H(), 0.0)) # Inertia terms form += qs.integral(reg.all, nfft, -par.rho() * qs.dtdt(qs.dof(fld.u)) * qs.tf(fld.u))

# Load interaction: Center point load form += qs.integral(reg.center_point_load_target, nfft, qs.array3x1(0.0, 0.0, -200.0 * qs.sn(1)) * qs.tf(fld.u))

# Rayleigh mass damping only: C = alpha * M alpha = 3.0 form += qs.integral(reg.all, -alpha * par.rho() * qs.dt(qs.dof(fld.u)) * qs.tf(fld.u))

# Continuation logic: isrisingbutnottoomuch = False umaxprev = qs.allmax(reg.material_from_paper_target, maxuf2, 2) ubkp = qs.vec(form) ubkp.setdata() nlindex = 0 maxnlits = 10 while nlindex < 5: numnlits = form.allsolve(relrestol=1e-06, maxnumit=1000, nltol=1e-05, maxnumnlit=maxnlits, relaxvalue=-1) curumax = qs.allmax(reg.material_from_paper_target, maxuf2, 2) if curumax > umaxprev and (umaxprev == 0 or curumax < 1.5*umaxprev) and numnlits < maxnlits: isrisingbutnottoomuch = True break qs.printonrank(0, "Not rising - Retrying: umaxprev was " + str(umaxprev) + " umax is " + str(curumax)) # Reset and raise the guess for the next attempt: nlindex = nlindex+1 qs.setdata((1.0+nlindex*0.05)*ubkp)

# Value output: Max u f2 var.discrete = qs.allmax(reg.material_from_paper_target, maxuf2, 2)

if isrisingbutnottoomuch: qs.setoutputvalue("Frequency", freq, freq) qs.setoutputvalue("Max u f2 - arc "+str(arcindex), var.discrete, freq) else: dir = -dir arcindex = arcindex + 1 if arcindex == 2: freq = freqmin dir = 1 fld.u.setvalue(reg.all) if arcindex == 4: break

freq = freq + dir*stepYour simulation is now ready to run!

Step 6 - Plot results

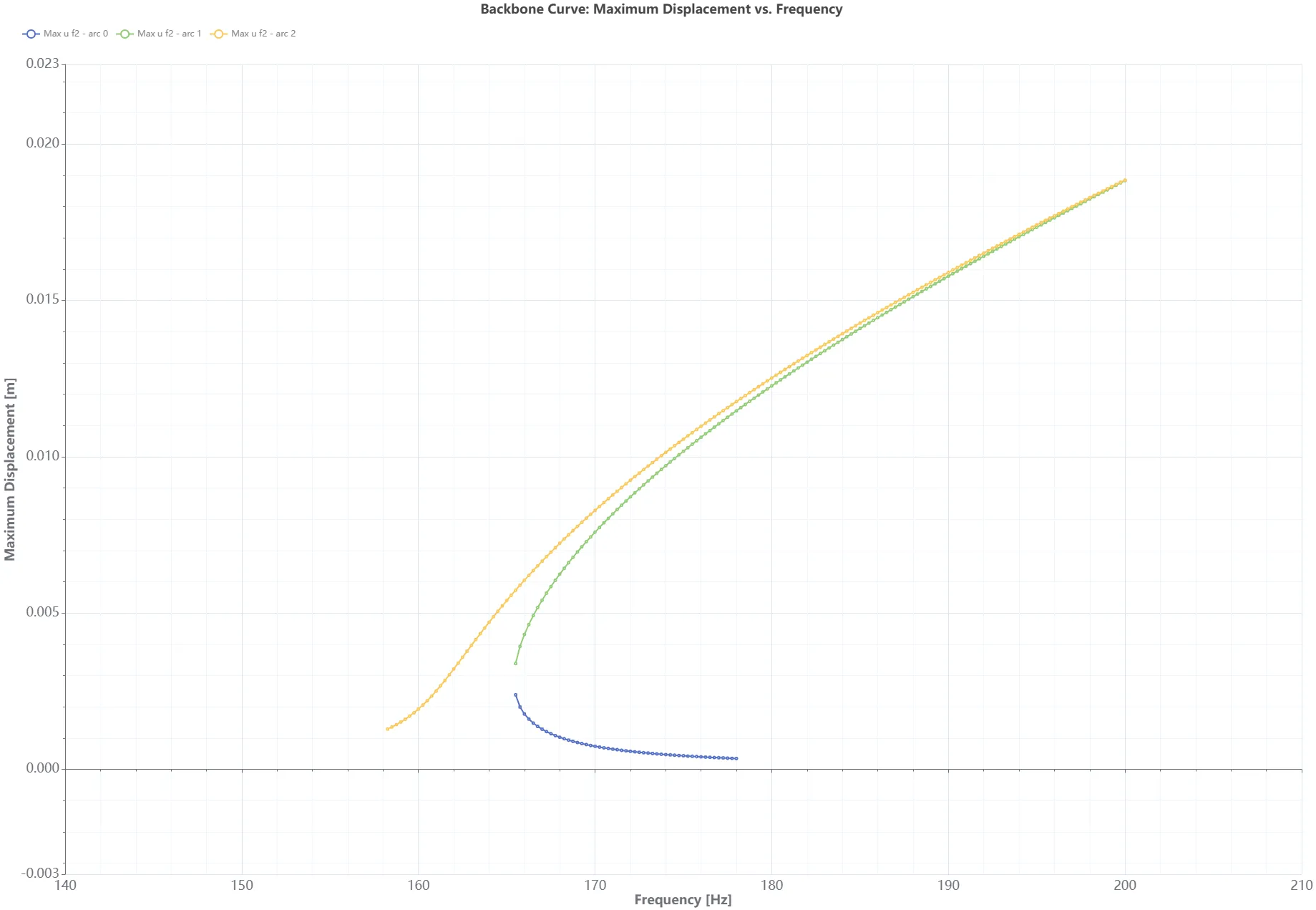

Section titled “Step 6 - Plot results”In the Simulations section, add three plots called Max u f2 - arc 0, Max u f2 - arc 1, and Max u f2 - arc 2 as a function of frequency. The results should resemble this:

In the Simulations section, add three plots named Max u f2 – arc 0, Max u f2 – arc 1, and Max u f2 – arc 2, each showing the maximum displacement. Plot the result as a function of Frequency. The results should look similar to the example below:

The figure illustrates the backbone curve bending towards higher frequencies.

References

Section titled “References”Footnotes

Section titled “Footnotes”-

Paper: Parallel harmonic balance method for analysis of nonlinear dynamical systems https://asmedigitalcollection.asme.org/GT/proceedings/GT2020/84232/V011T30A028/1095387 ↩

-

Demo project: Backbone curve of a clamped-clamped beam https://allsolve.quanscient.com/#/projects/428c622d-977f-4e82-a027-a51d5a489875 ↩