Meshing

In Quanscient Allsolve, meshing is done in the Simulations section.

Each project can contain multiple meshes. These depend on the geometry and are generated based on the given mesh settings. After a mesh has been successfully generated, it can be used in all simulations.

Mesh presets

Section titled “Mesh presets”If there are no specific requirements for the mesh, one of the following predefined settings can be selected: coarse, default, or fine. To configure settings manually, select expert settings.

- Coarse

- Used mesher: mesh refiner

- Maximum size: 20% of the geometry size

- Curvature enhancement:

- Target maximum width-to-height ratio:

- Default

- Used mesher: mesh refiner

- Maximum size: 10% of the geometry size

- Curvature enhancement:

- Target maximum width-to-height ratio:

- Fine

- Used mesher: mesh refiner

- Maximum size: 5% of the geometry size

- Curvature enhancement:

- Target maximum width-to-height ratio:

Expert settings

Section titled “Expert settings”With expert settings all meshing parameters are tunable.

Used Mesher

Section titled “Used Mesher”Basic option follows the given size restrictions accurately and typically works well if you can ensure that the size settings are suitable for all geometrical entities, but it cannot deduce suitable sizing automatically.

Mesh refiner (default)

Section titled “Mesh refiner (default)”Mesh refiner attempts to automatically deduce suitable sizing that follows the given settings but also ensures mesh quality. For example, if maximum size setting applies to some entity, the sizing for nearby entities should also be restricted to avoid ill-shaped mesh elements.

If meshing fails due to low quality elements, mesh refiner is also able to retry by refining the sizing in places where these elements appeared.

Size settings

Section titled “Size settings”Size settings allow to restrict the mesh size. These apply globally unless otherwise stated. Maximum size, curvature enhancement, target maximum width-to-height ratio, and mesh refinement are settings that set an upper bound for the mesh size. The effect of these can be limited by setting minimum size. The resulting sizing can be fine-tuned with scale factor, which applies after all other settings.

Maximum and minimum size

Section titled “Maximum and minimum size”Maximum size sets the absolute maximum size for mesh elements. This requirement is always fulfilled.

Minimum size sets the absolute minimum size, but note that this cannot be strictly enforced. For example, each curve entity should have at least one mesh element, and the setting cannot be followed if the given minimum is greater than the curve length. This setting should be seen as a way to limit the effect of the other settings that set an upper bound for the mesh size.

Curvature enhancement

Section titled “Curvature enhancement”Curvature enhancement limits the mesh size based on the curvature of the geometrical entities. This improves the accuracy with which the mesh follows curved geometries.

The given value determines the minimum number of elements that are used to represent a full circle (elements per 360 degrees). Use value to disable this feature.

Target maximum width-to-height ratio

Section titled “Target maximum width-to-height ratio”This setting sets a target maximum width-to-height ratio of elements. The feature measures distance to nearby entities and attempts to limit the mesh size in thin regions where the given target would otherwise be violated.

For example, consider two parallel surfaces whose distance from each other is , and suppose we are using the default value for target maximum width-to-height ratio. Then the mesh size should not exceed or the target maximum would be violated in the volume between them.

It should be noted that the setting is not fully exhaustive and is only used to limit the mesh size when it is clear that the requested maximum width-to-height ratio would otherwise be violated. There is no way to directly control the aspect ratios of individual mesh elements.

This feature is only available with mesh refiner. Use value to disable the feature. Unless disabled, the value should be at least . Lower values typically improve the average element quality but increase the number of elements, so there is no single optimal value for all cases.

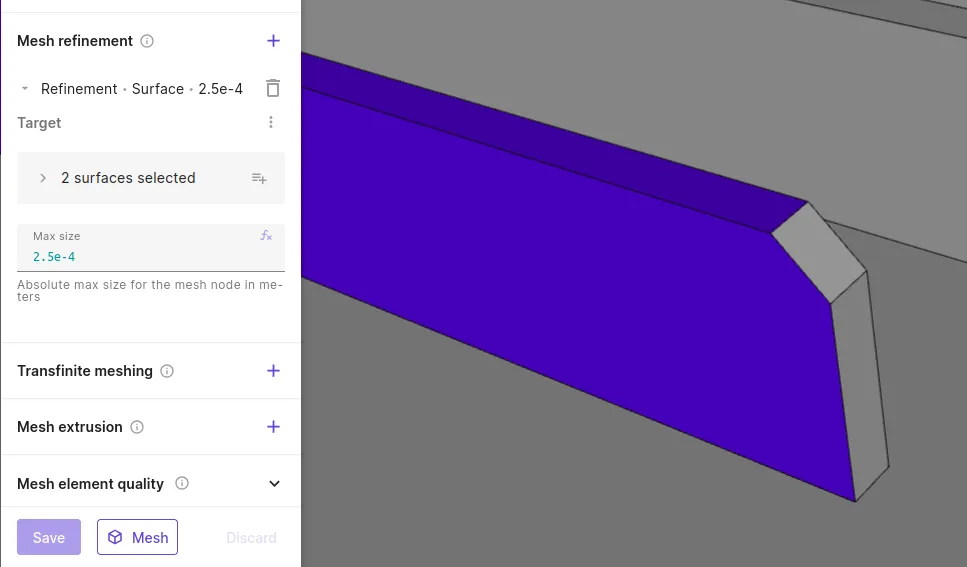

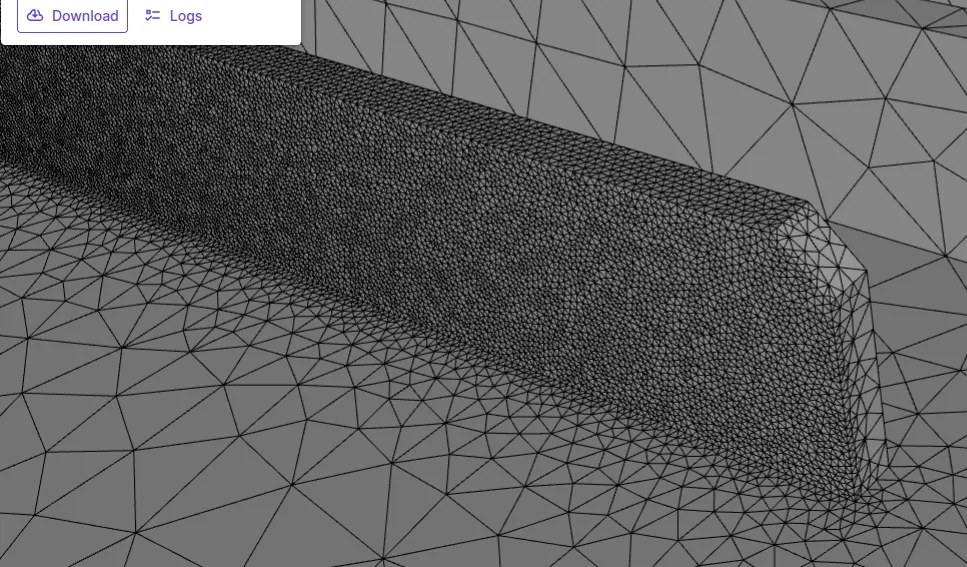

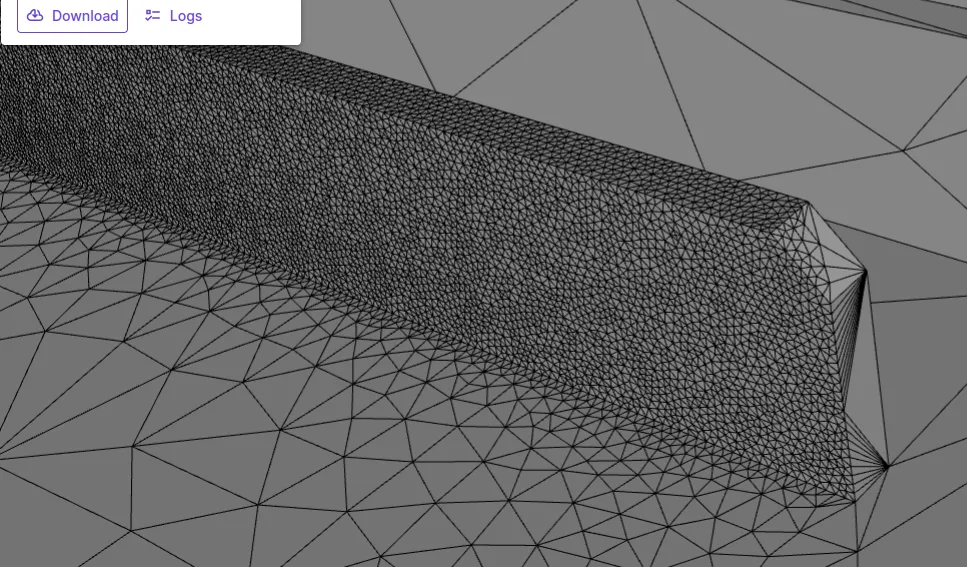

Mesh refinement

Section titled “Mesh refinement”Mesh refinements work like maximum size setting but only apply to specific geometrical entities. Mesh refinement can target volumes, surfaces or curves. Once the target type is selected, fill in the refinement value in meters. Any number of refinements can be added.

| Mesh refinement target | Meshing results (mesh refiner) | Meshing results (basic) |

|---|---|---|

|  |  |

Scale factor

Section titled “Scale factor”Scale factor is a multiplier applied to the mesh sizing before the mesh is generated. The scaling is applied after all other sizing and does not affect structured meshing.

This is especially useful if the mesh requires fine-tuning. For example, if you would like to decrease (or increase) the element size by 10%, try scale factor (or ). Lower values (for example, for 10% sized elements) typically also work, but note that values much greater than are not guaranteed to work. It is not always possible to coarsen the mesh, and the mesh quality may deteriorate especially in case of curved geometries.

Curved mesh

Section titled “Curved mesh”This option enables the use of curved, second-order elements for better accuracy on curved geometries. The first-order mesh is always generated first. If requested, all elements are then converted to second-order elements that capture the geometry more accurately. Finally, mesh optimization is performed to ensure validity of the resulting mesh. This may sometimes fail but typically works well if the initial mesh is not too coarse.

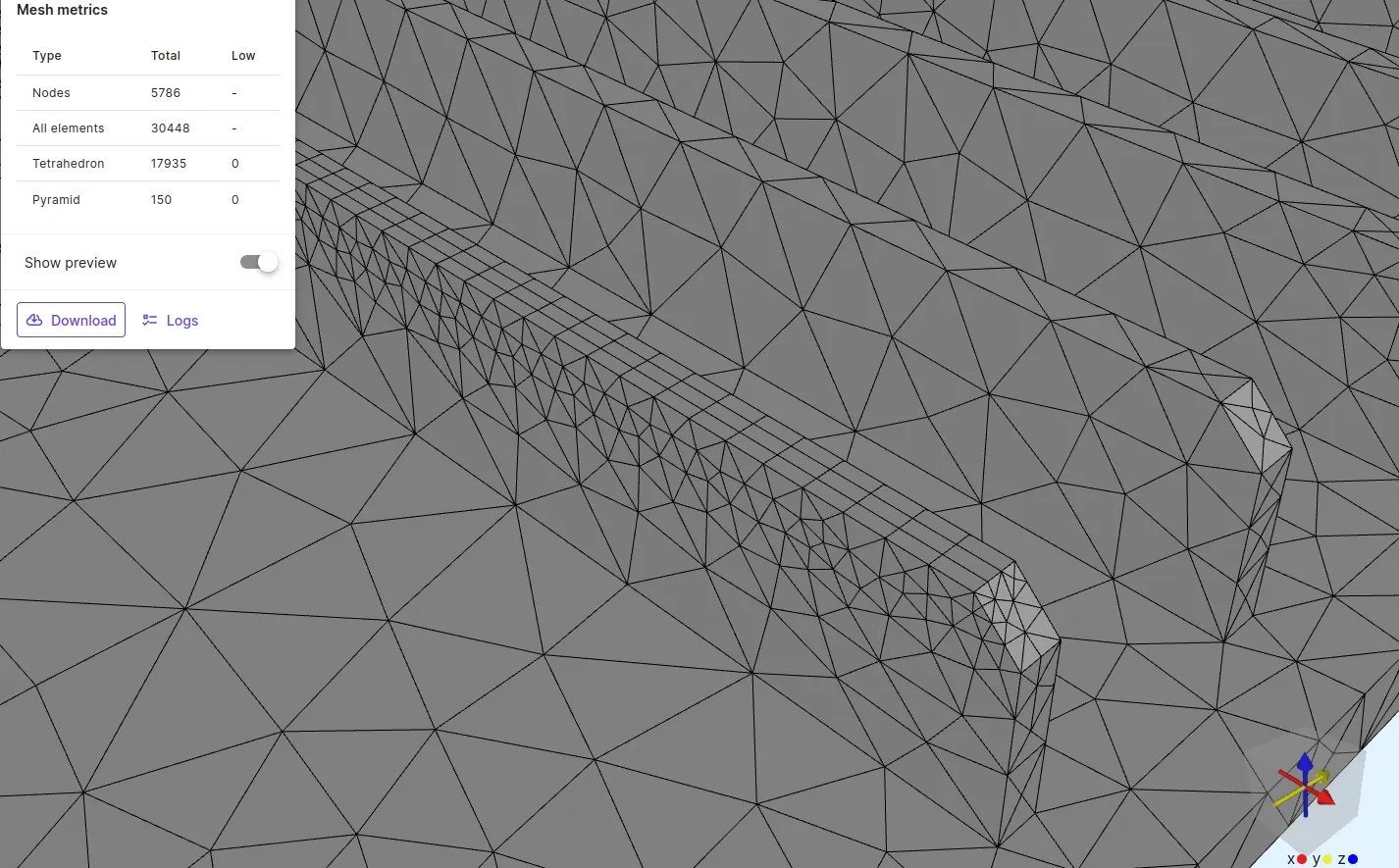

Structured meshing

Section titled “Structured meshing”By default, all geometrical entities are meshed using unstructured meshing algorithms that handle arbitrarily complex geometries. When the geometry satisfies certain simplifying assumptions, it may be possible to mesh it using one of the structured meshing algorithms detailed below. It is also possible to combine structured and unstructured meshing so that selected entities are meshed using a type of structured meshing and the rest are meshed unstructured afterwards.

Structured meshing is the only way to create nonsimplicial elements (for example quadrangles and hexahedra). When unstructured meshing is used to fill entities that have quadrangles on the boundary, pyramids are generated to combine these with tetrahedra.

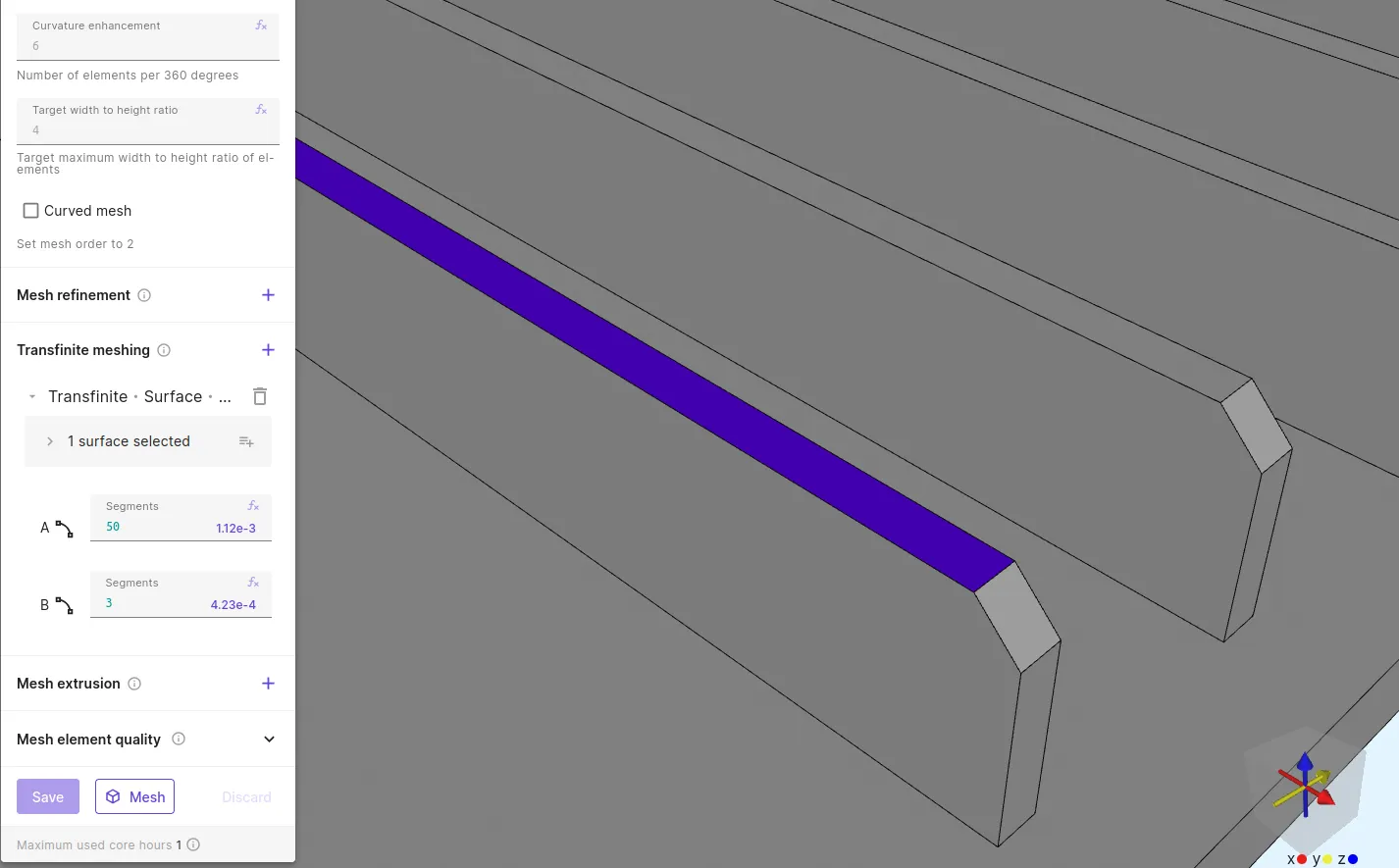

Transfinite meshing

Section titled “Transfinite meshing”Transfinite meshing allows you to mesh curves, surfaces akin to a rectangle, or volumes akin to a box by specifying the number of elements to use on the curves in each direction. Surfaces and volumes are filled with quadrangles and hexahedra using transfinite interpolation.

- Choose the target entity (curve, surface, or volume) you want to set.

- Input values for each direction of curves in your selection (two curve segment counts surface targets and three for volume targets). As you hover over a curve label (A/B/C), the corresponding curve in the model view will be highlighted.

- The application calculates an average mesh element size based on your inputs. Aim to keep the ratios of the resulting lengths within a range of 1/3 to 3 for optimal results.

| Transfinite meshing target | Meshing results (mesh refiner) |

|---|---|

|  |

Mesh extrusion (simple)

Section titled “Mesh extrusion (simple)”Simple mesh extrusions use unstructured meshing to mesh bottom surfaces and extrude the elements of this surface mesh to obtain a 3D mesh. They can be applied to volumes whose curves and surfaces are either horizontal or vertical (perpendicular or parallel to the -axis).

The number of elements to use in the -direction will be specified by the user as follows. To make the mesh consistent with the geometry, extrusion should match with all different -levels that have horizontal entities. This prescribes a minimum number of layers. The number of sublayers to use within each layer can be selected freely, and the user is required to input these sublayer counts.

To use this feature, add a simple extrusion by clicking the the + icon in mesh extrusion tab. This will create an empty extrusion which can then be configured.

- Target: Select the volumes where extrusion is applied.

- Sublayers: Select the sublayer counts as explained above.

- Overlap Mode: You can choose whether to allow or prevent generation of pyramids on the sides of extruded volumes. Prevent mode will abort meshing with error if any extruded volume is detected to share a vertical surface with a volume that is not extruded. This check is not included in Allow mode.

Mesh extrusions are especially useful if the geometry has thin layers where unstructured meshing is difficult. Meshing in 2D is typically much easier than in 3D, and extrusion preserves the element quality. It also enables different mesh sizing in horizontal and vertical direction.

The conformity of the resulting mesh is automatically ensured. For example, when extrusion is applied to stacked volumes, the surface mesh of the lower volume must already be generated in a way that allows the extrusion to continue to the entities in the upper volume. This can usually be achieved without any problems. However, issues may occur if the upper volume contains entities that are essentially the same as in the lower volume but slightly misplaced due to issues with the geometry. In this case extrusion might fail during the 2D meshing phase or it might result in thin mesh elements.