Packaging 001 - FCBGA free warpage

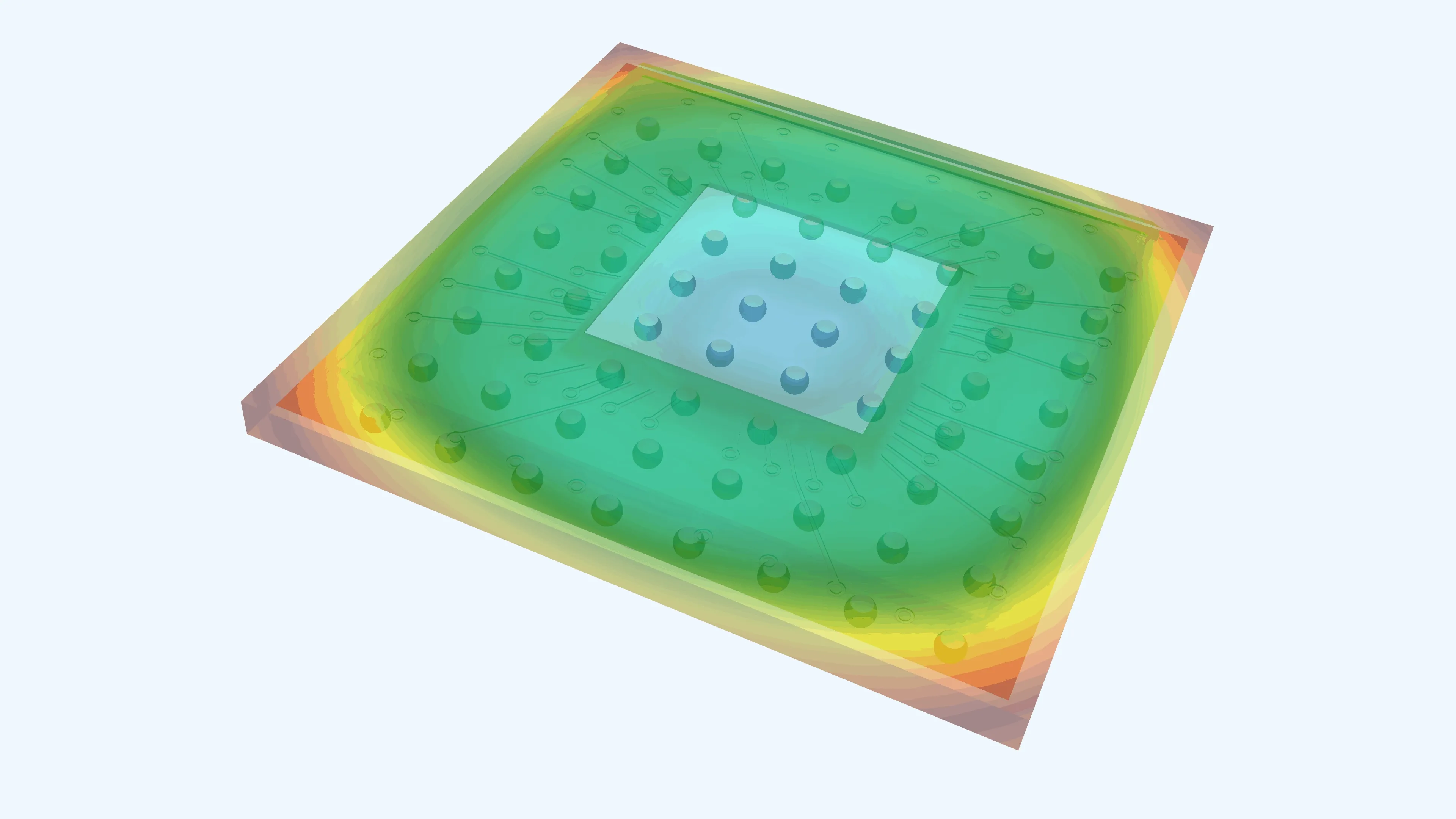

In this example, warpage and thermal stresses due to thermal expansion are considered for a Flip Chip Ball Grid Array (FCBGA) semiconductor packaging solution.

Simulation setup guide

Section titled “Simulation setup guide”Below, you’ll find a simplified guide for setting this up in Quanscient Allsolve.

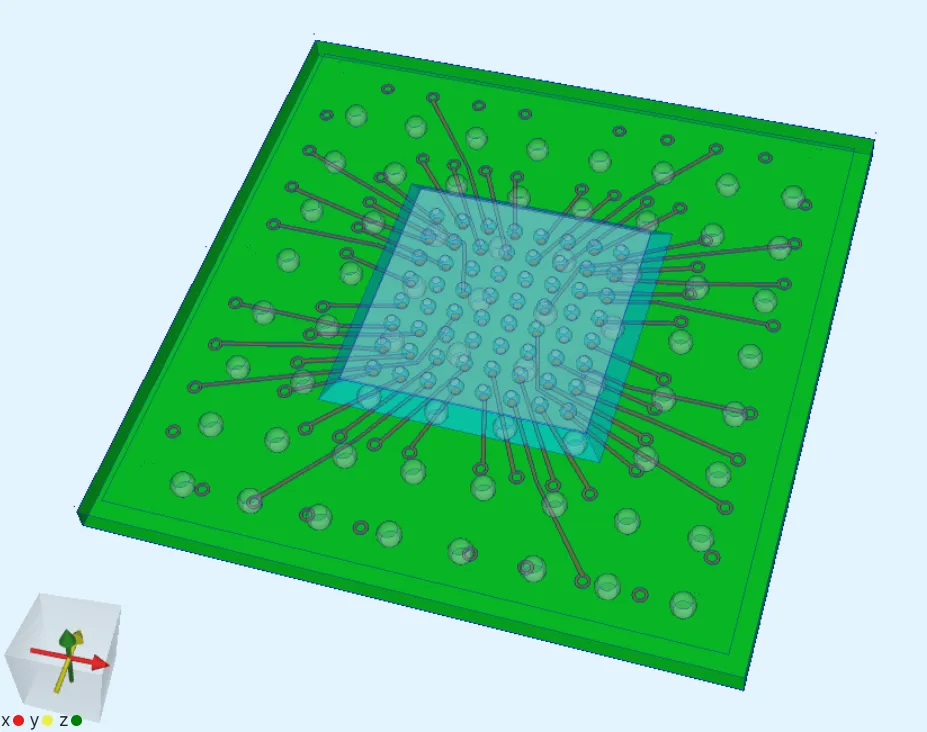

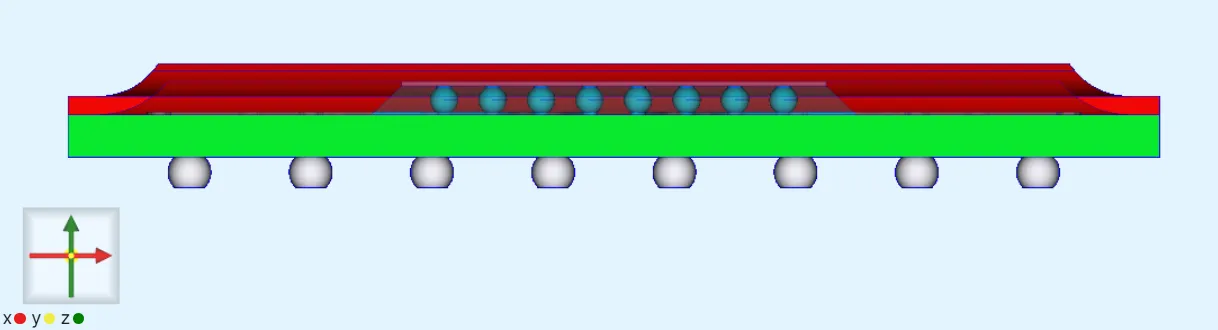

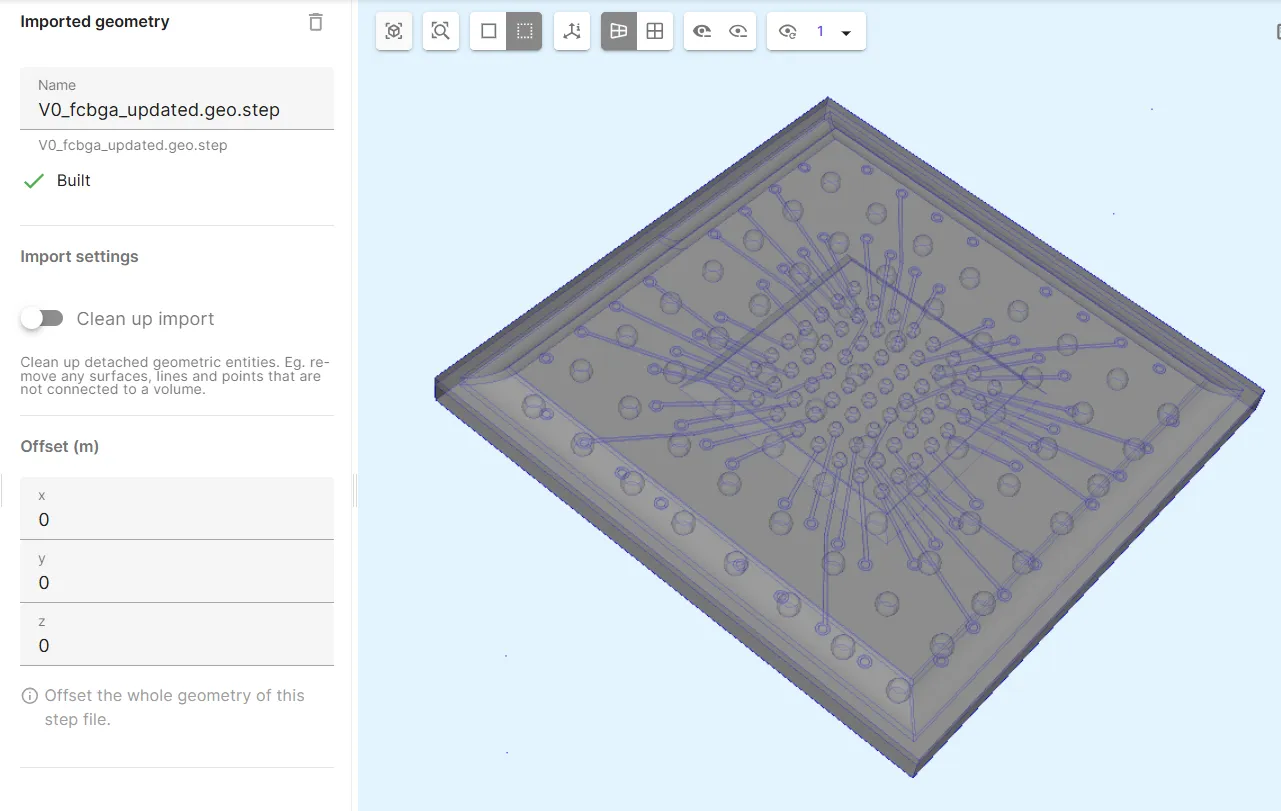

Step 1 - Import the geometry

Section titled “Step 1 - Import the geometry”In the Geometry section, start by importing a .step file for your FCBGA model:

File download link: fcbga.step

Step 2 - Define variables

Section titled “Step 2 - Define variables”Go to the Common sidebar.

Define variables:

| Name | Description | Expression |

|---|---|---|

| Tsf | Stress free temperature [K] | 273 + 150 |

| Tend | Final temperature [K] | 273 + 25 |

Step 3 - Define shared regions

Section titled “Step 3 - Define shared regions”Continuing in the Common sidebar, define the following 9 shared regions:

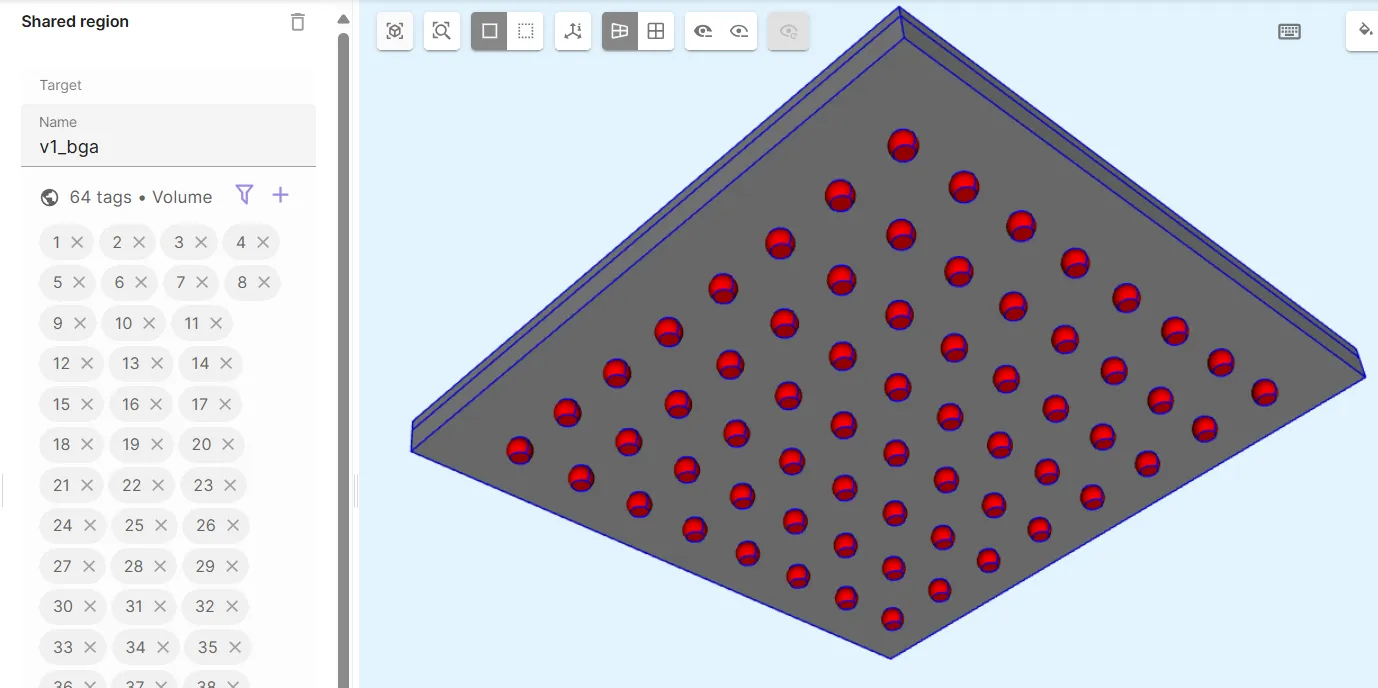

- Define the ball grid array volume shared region

v1_bga.

-

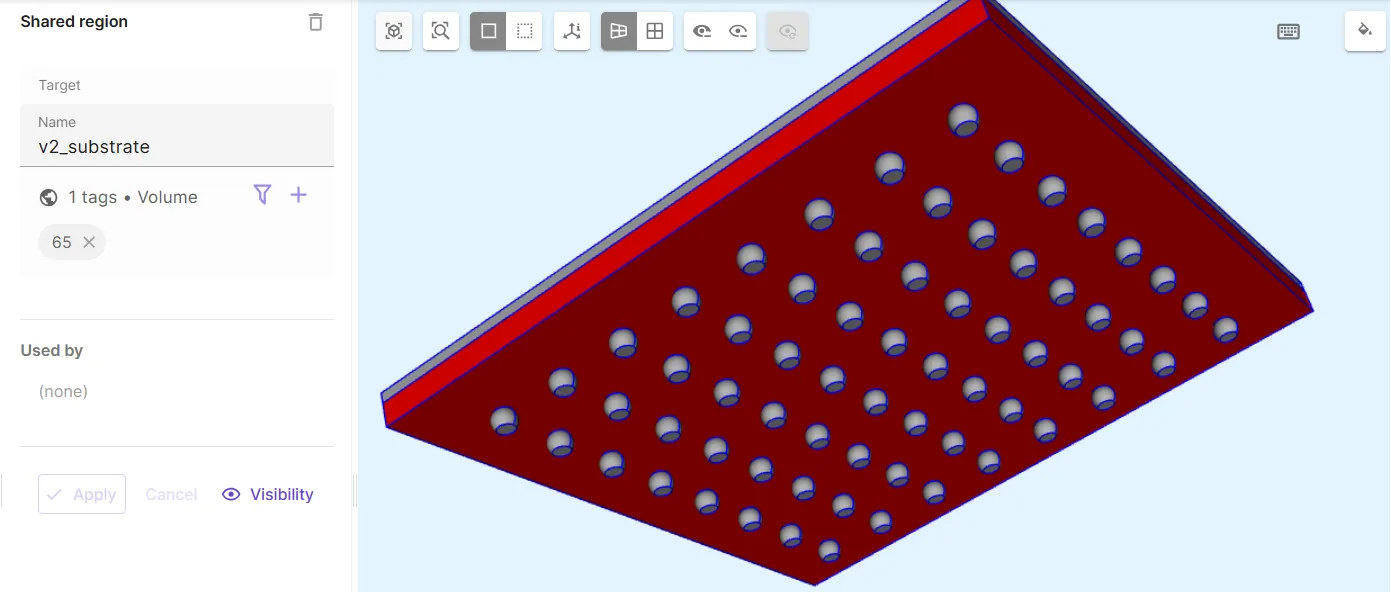

Define the substrate volume shared region

v2_substrate.

-

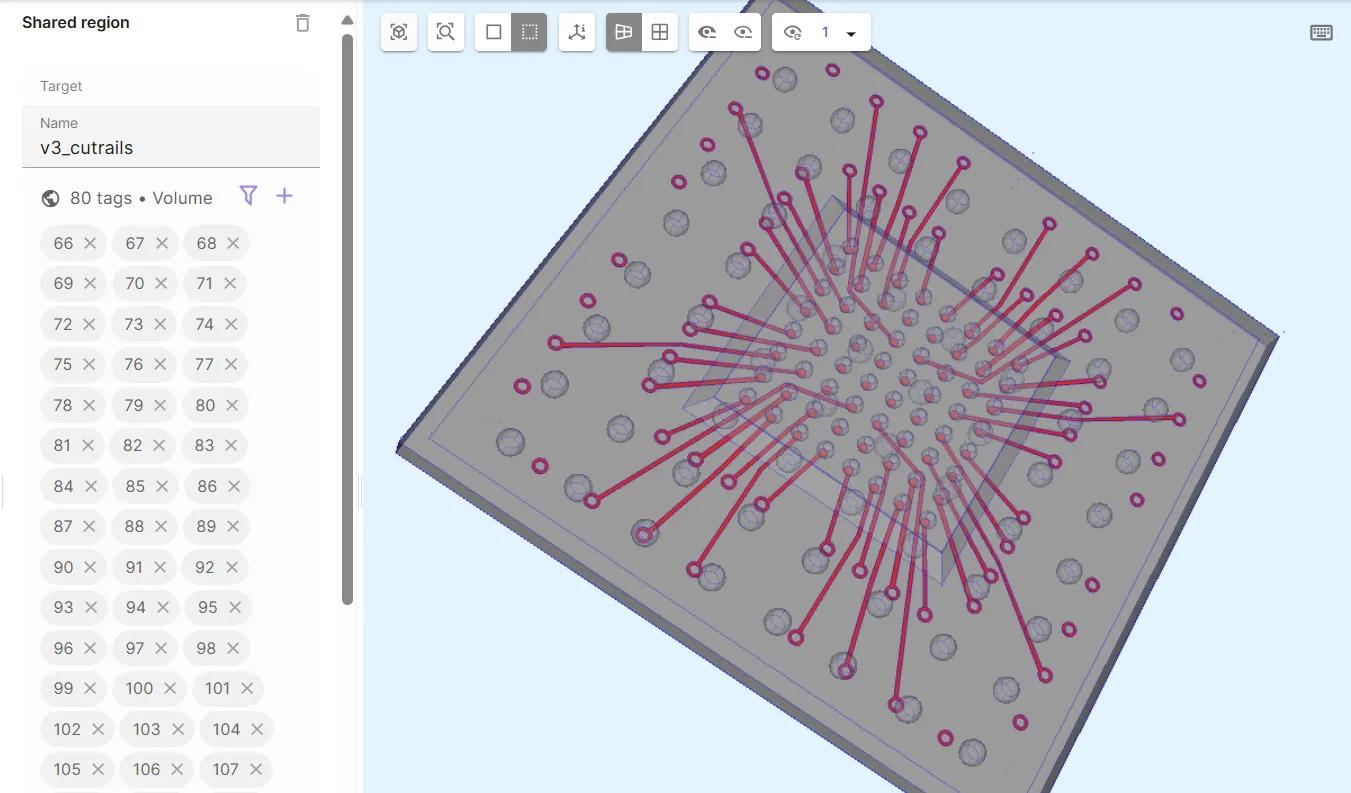

Define the cut rails volume shared region

v3_cutrails.

-

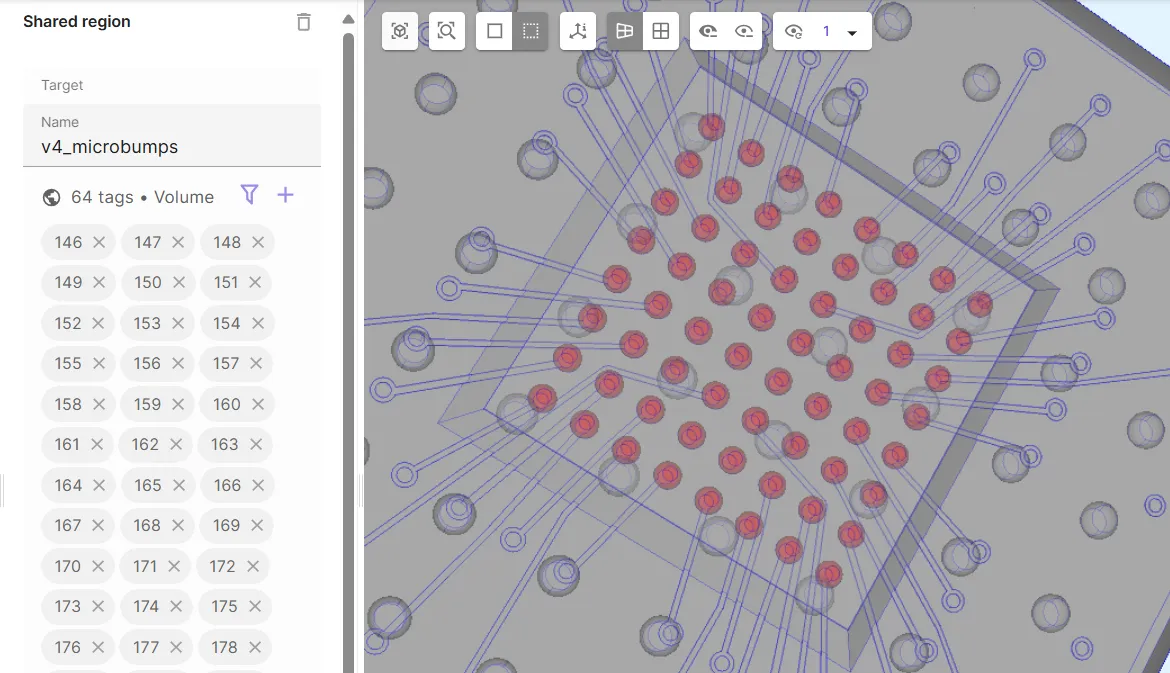

Define the micro bumps volume shared region

v4_microbumps.

-

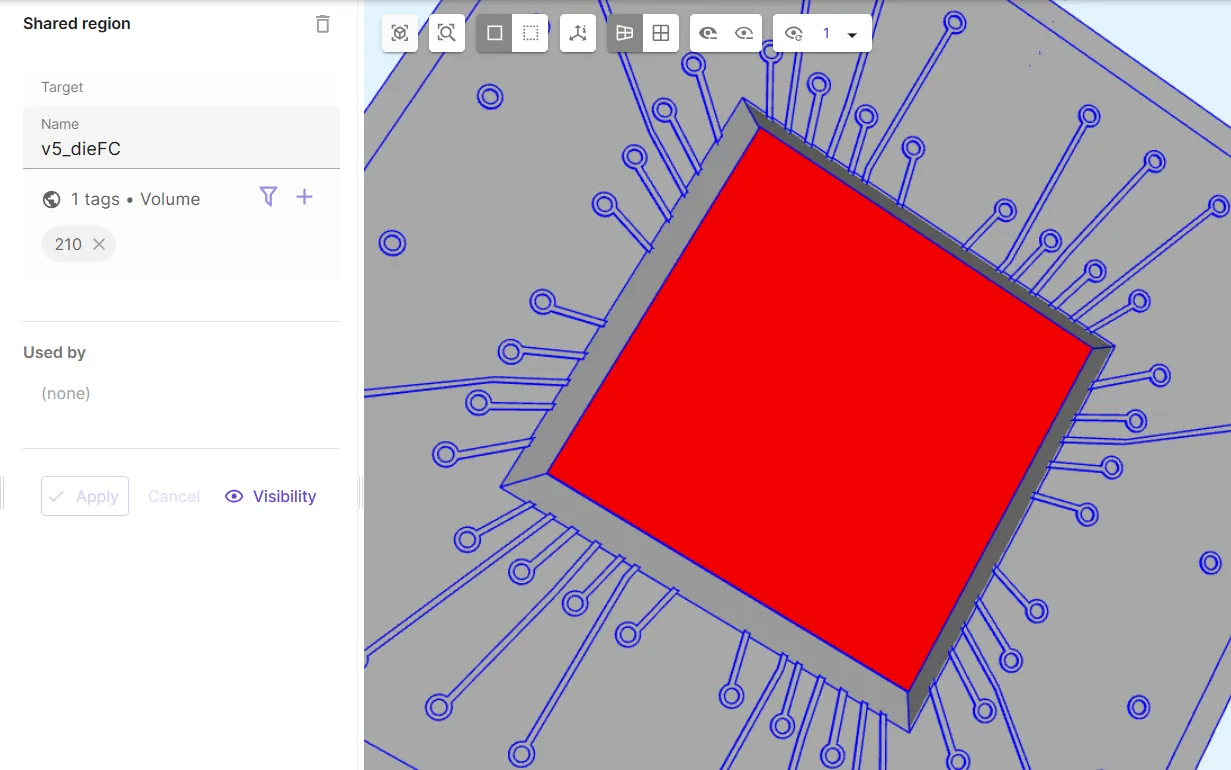

Define the flip chip volume shared region

v5_dieFC.

-

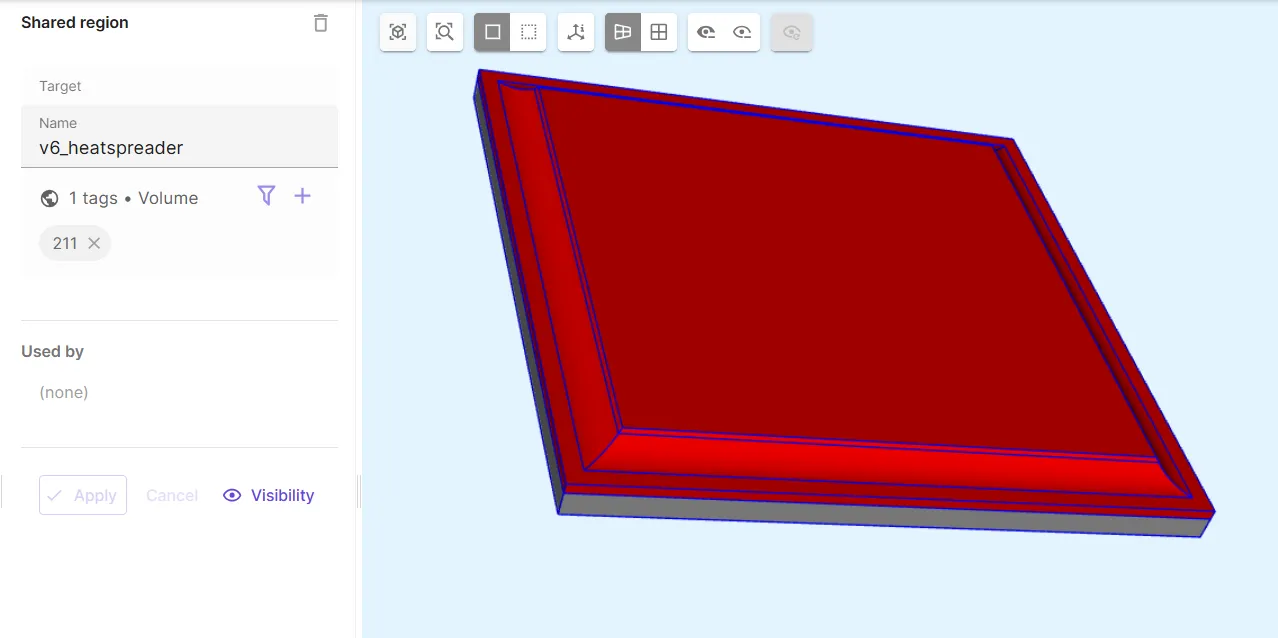

Define the heat spreader volume shared region

v6_heatspreader.

-

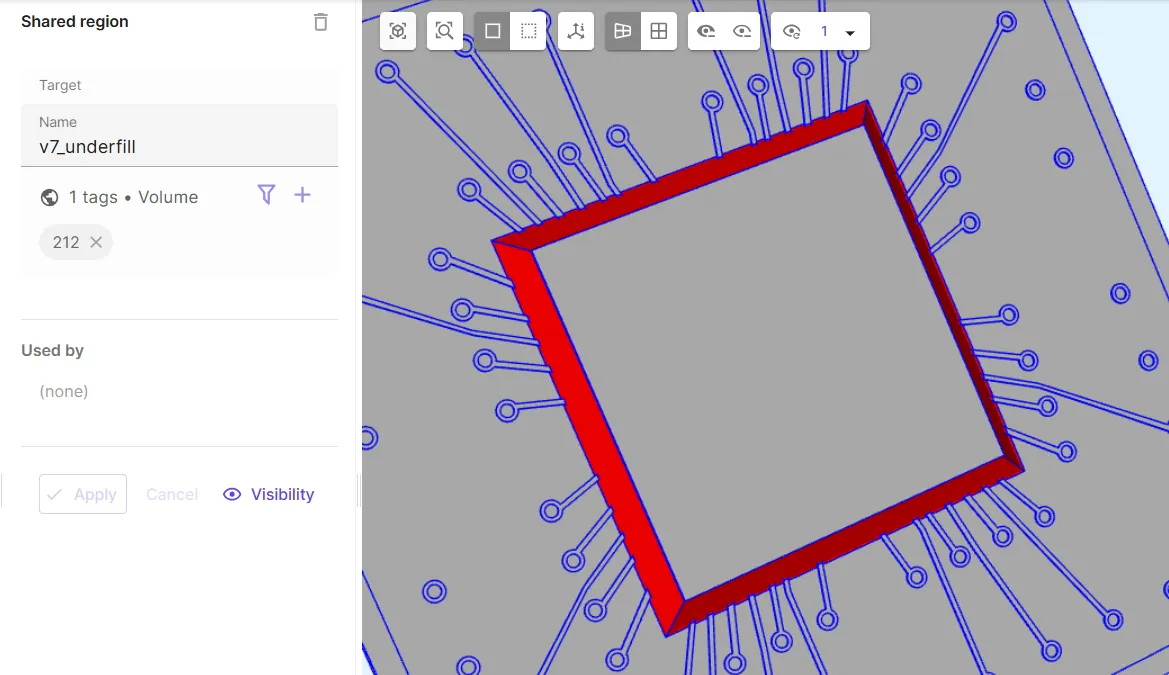

Define the underfill volume shared region

v7_underfill.

-

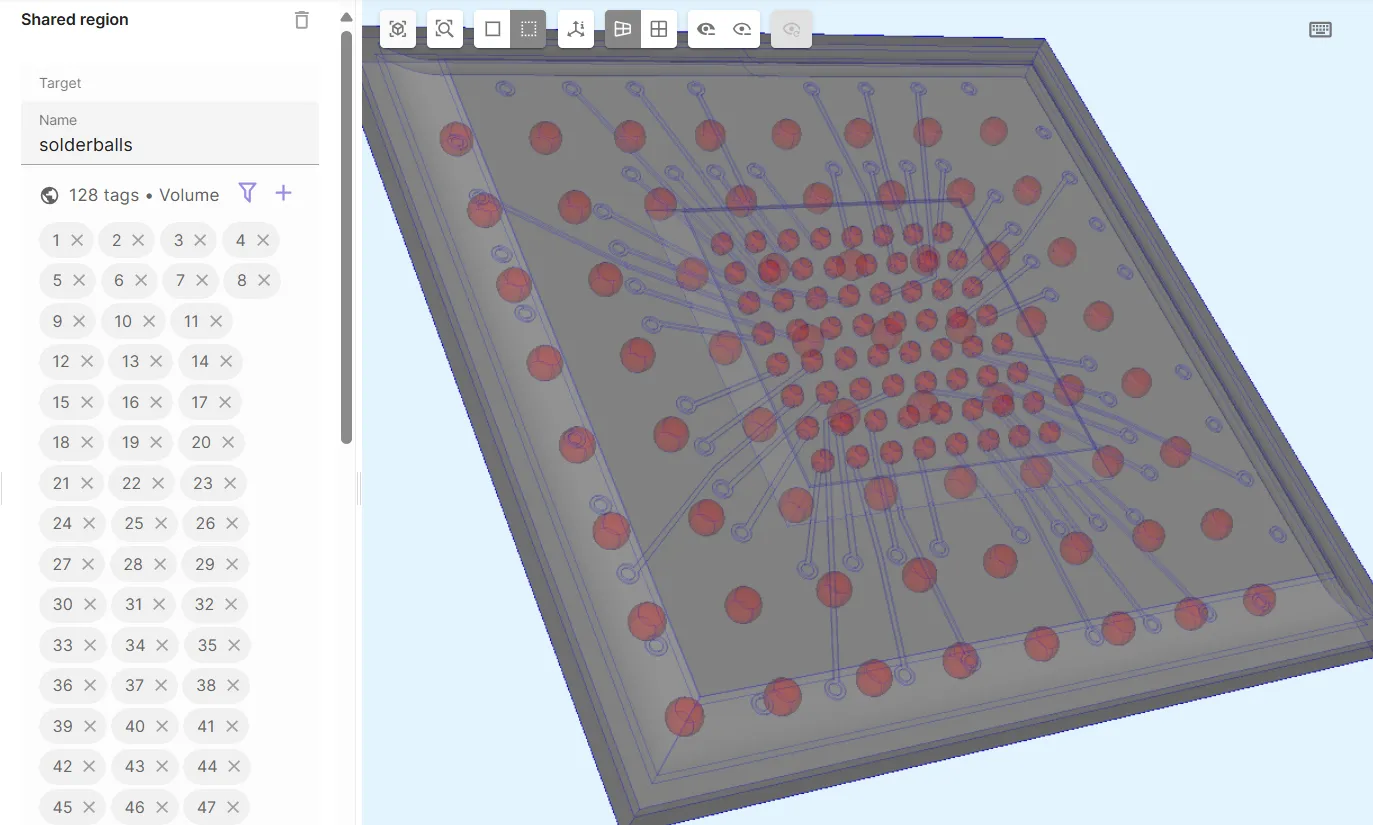

Define the solder balls volume shared region

solderballs, which contains all volumes from thev1_bgaandv4_microbumpsregions.

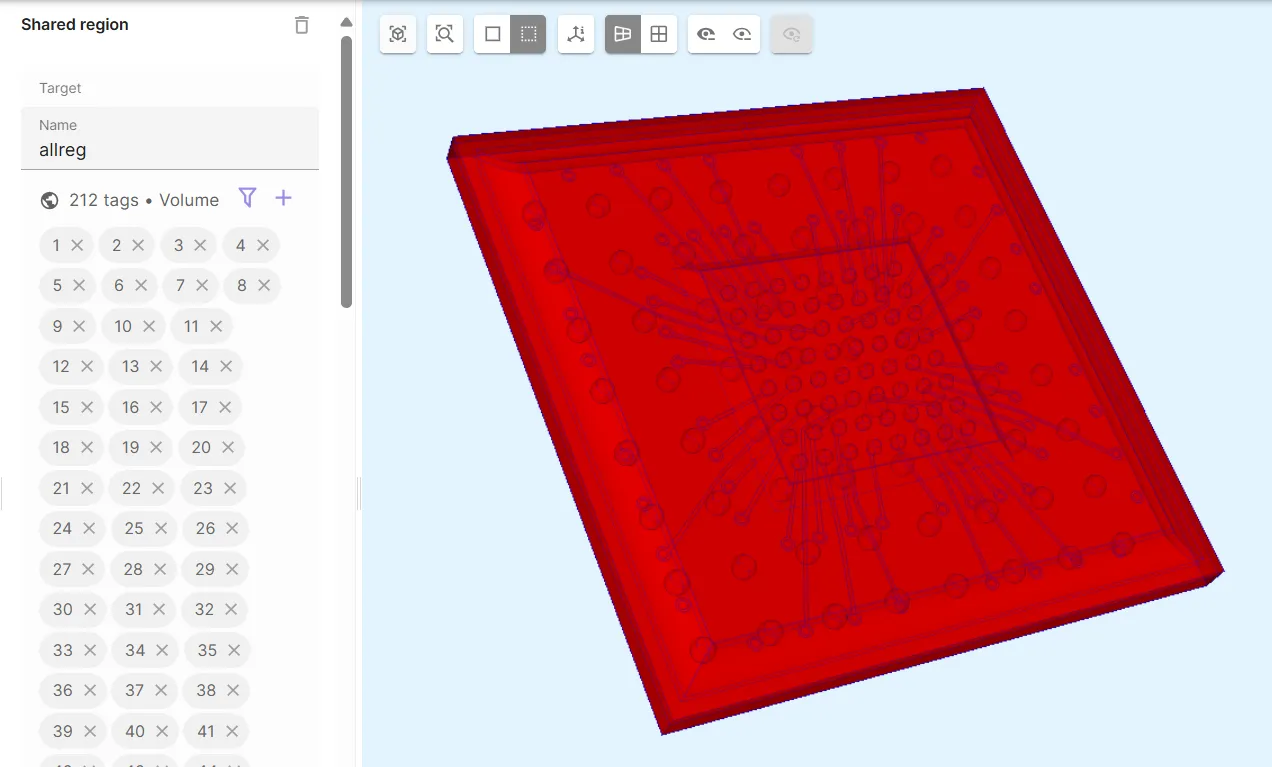

- Define the all regions volume shared region

allreg, which contains all volumes in the model.

Step 4 - Define the materials

Section titled “Step 4 - Define the materials”Finally, in the Physics section, define the model materials.

In this example, 3 new materials are created:

The 3 following predefined materials are also used:

- Aluminium

- Integrated heat spreader

- Copper

- Cut rails

- Silicon dioxide

- Flip chip

See the dedicated subsections below for detailed material definitions.

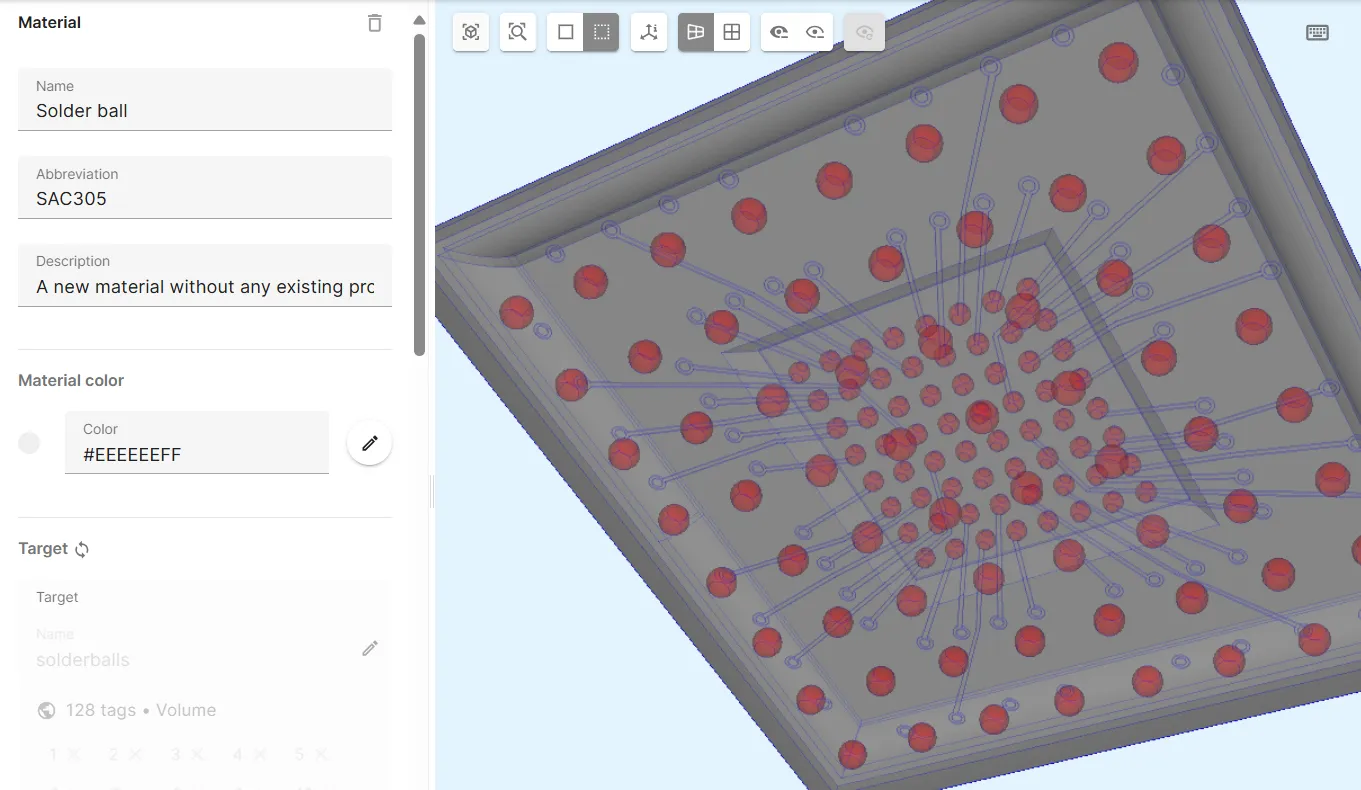

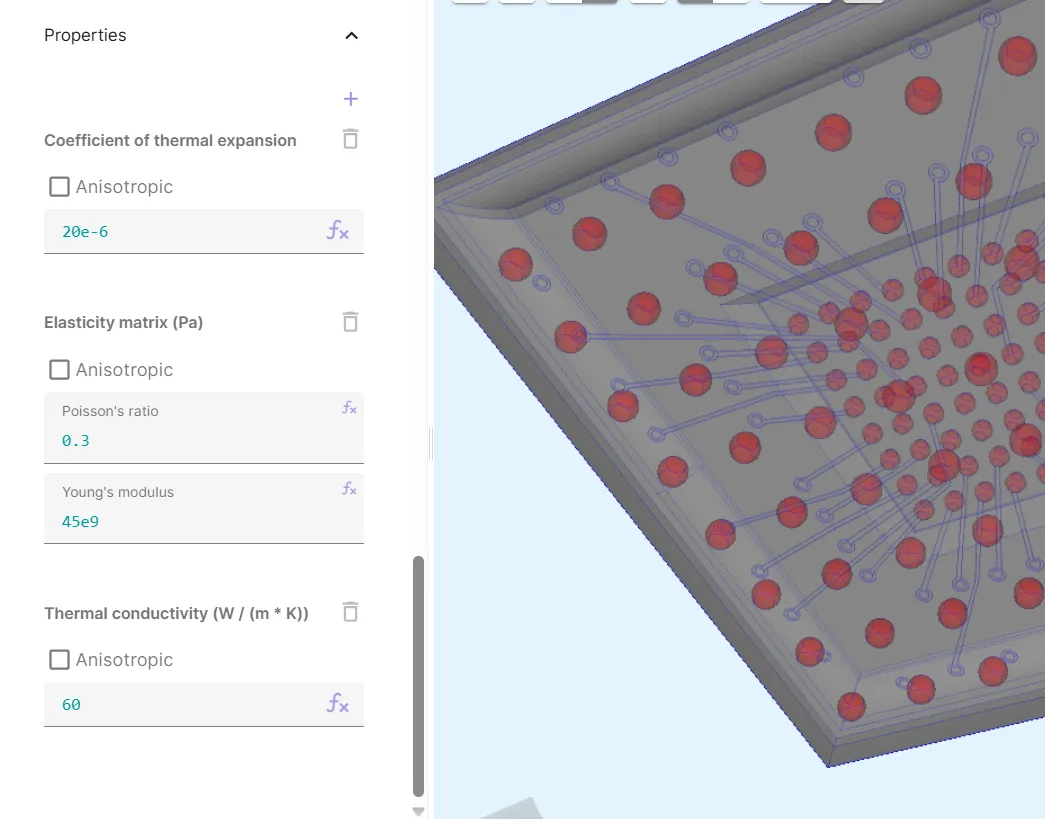

Material 1 - SAC305

Section titled “Material 1 - SAC305”The SAC305 material is defined for the FCBGA solder balls.

Create a new material:

| Name | Abbreviation | Material color | Target |

|---|---|---|---|

Solder ball | SAC305 | Light gray | The solderballs shared region |

Add properties to the material:

| Coefficient of thermal expansion | Elasticity matrix | Thermal conductivity |

|---|---|---|

20e-6 | Poisson’s ratio: 0.3 | 60 |

Young’s modulus: 45e9 |

Now, your SAC305 material is defined.

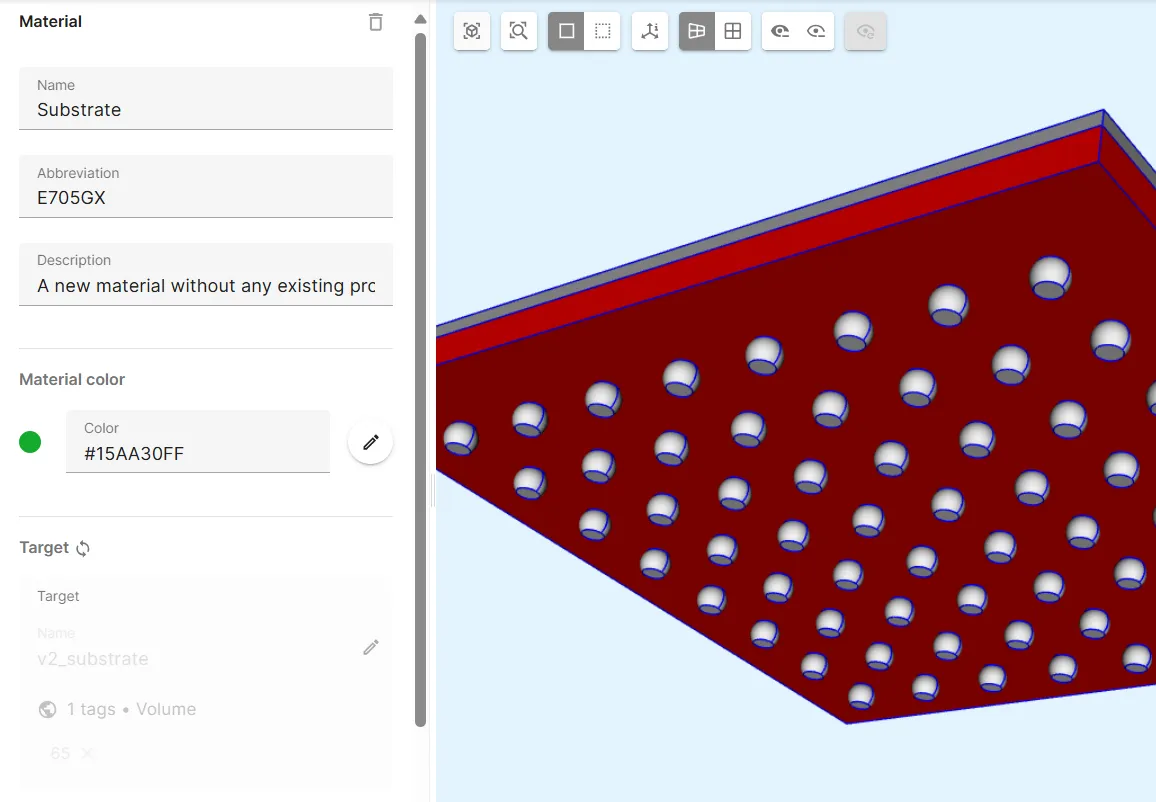

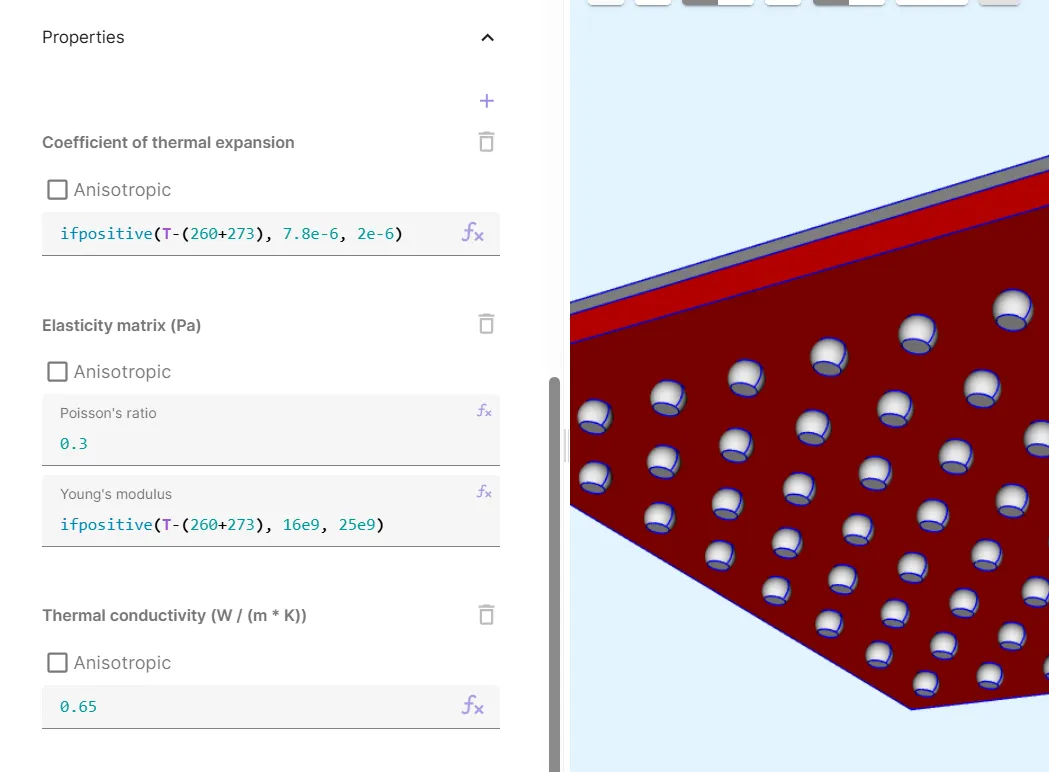

Material 2 - E705GX

Section titled “Material 2 - E705GX”The E705GX material is defined for the FCBGA substrate.

Create a new material:

| Name | Abbreviation | Material color | Target |

|---|---|---|---|

Substrate | E705GX | Green | The v2_substrate shared region |

Add properties to the material:

| Coefficient of thermal expansion | Elasticity matrix | Thermal conductivity |

|---|---|---|

ifpositive(T-(260+273), 7.8e-6, 2e-6) | Poisson’s ratio: 0.3 | 0.65 |

Young’s modulus: ifpositive(T-(260+273), 16e9, 25e9) |

Now, your E705GX material is defined.

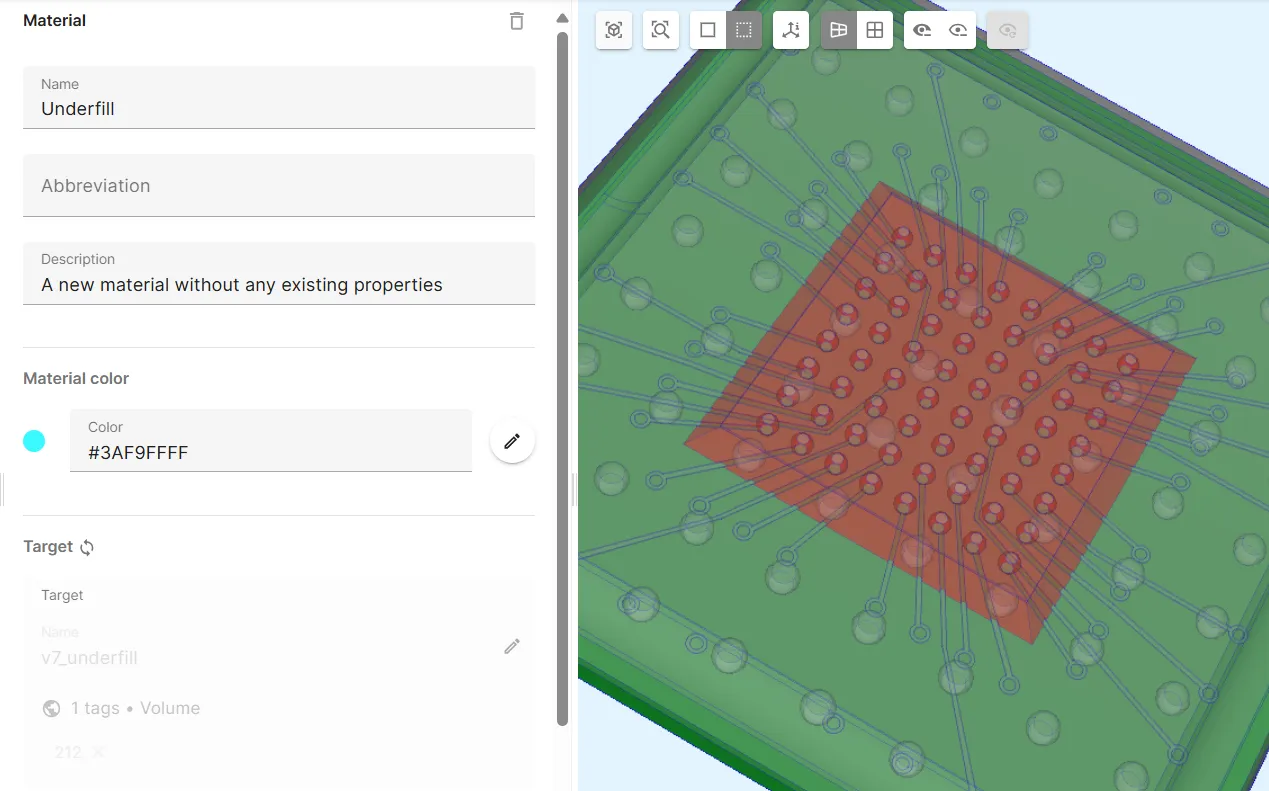

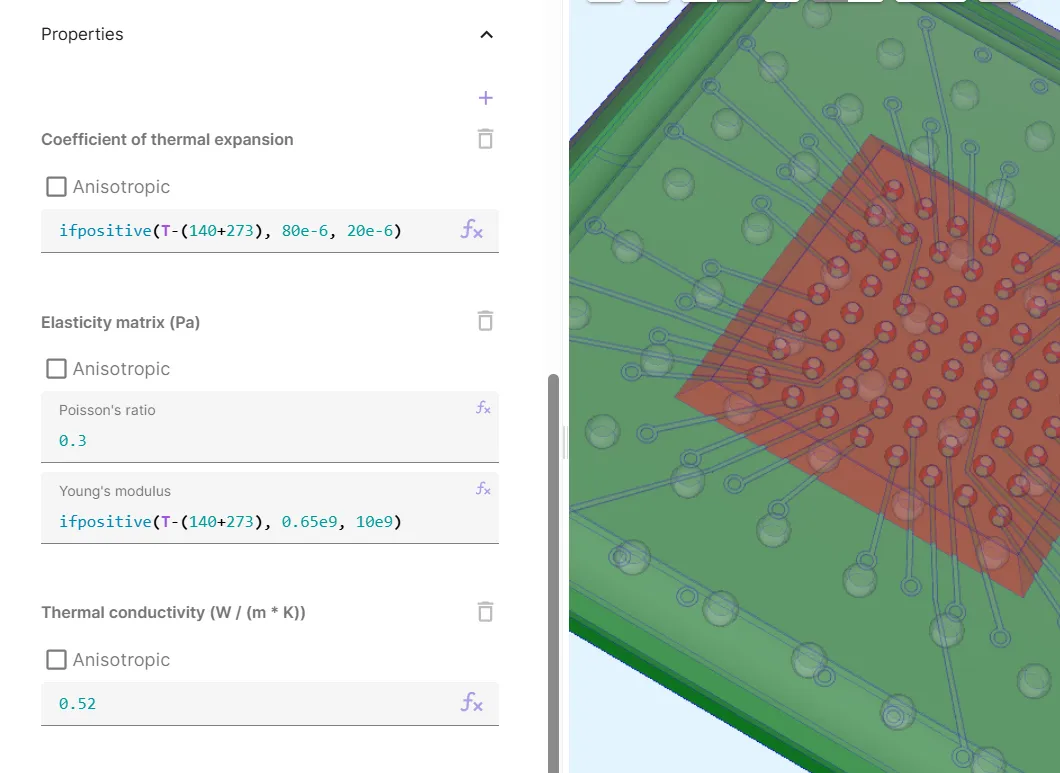

Material 3 - Underfill

Section titled “Material 3 - Underfill”The Underfill material is defined for the FCBGA underfill.

Create a new material:

| Name | Abbreviation | Material color | Target |

|---|---|---|---|

Underfill | Cyan | The v7_underfill shared region |

Add properties to the material:

| Coefficient of thermal expansion | Elasticity matrix | Thermal conductivity |

|---|---|---|

ifpositive(T-(140+273), 80e-6, 20e-6) | Poisson’s ratio: 0.3 | 0.52 |

Young’s modulus: ifpositive(T-(140+273), 0.65e9, 10e9) |

Now, your Underfill material is defined.

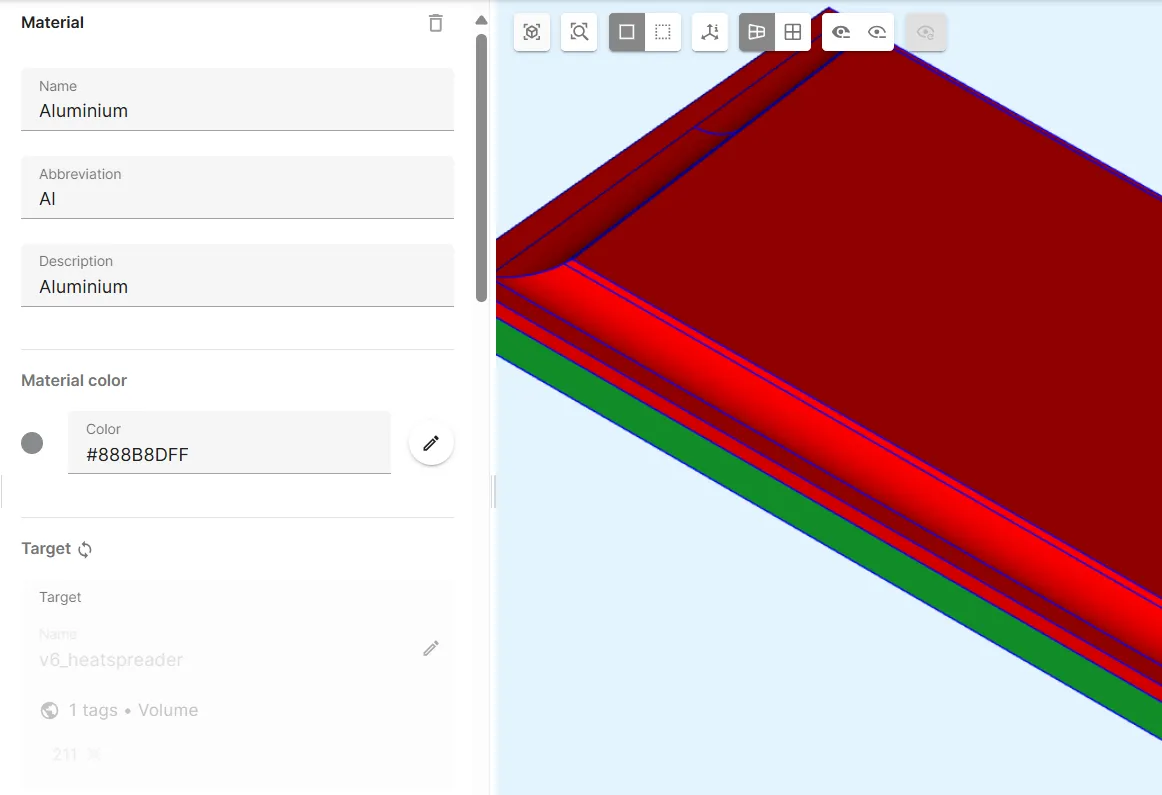

Material 4 - Aluminium

Section titled “Material 4 - Aluminium”The Aluminium material is assigned to the FCBGA heat spreader.

- Pick

Aluminiumfrom the materials library. - Select the

v6_heatspreadershared region as target.

Now, your Aluminium material is defined.

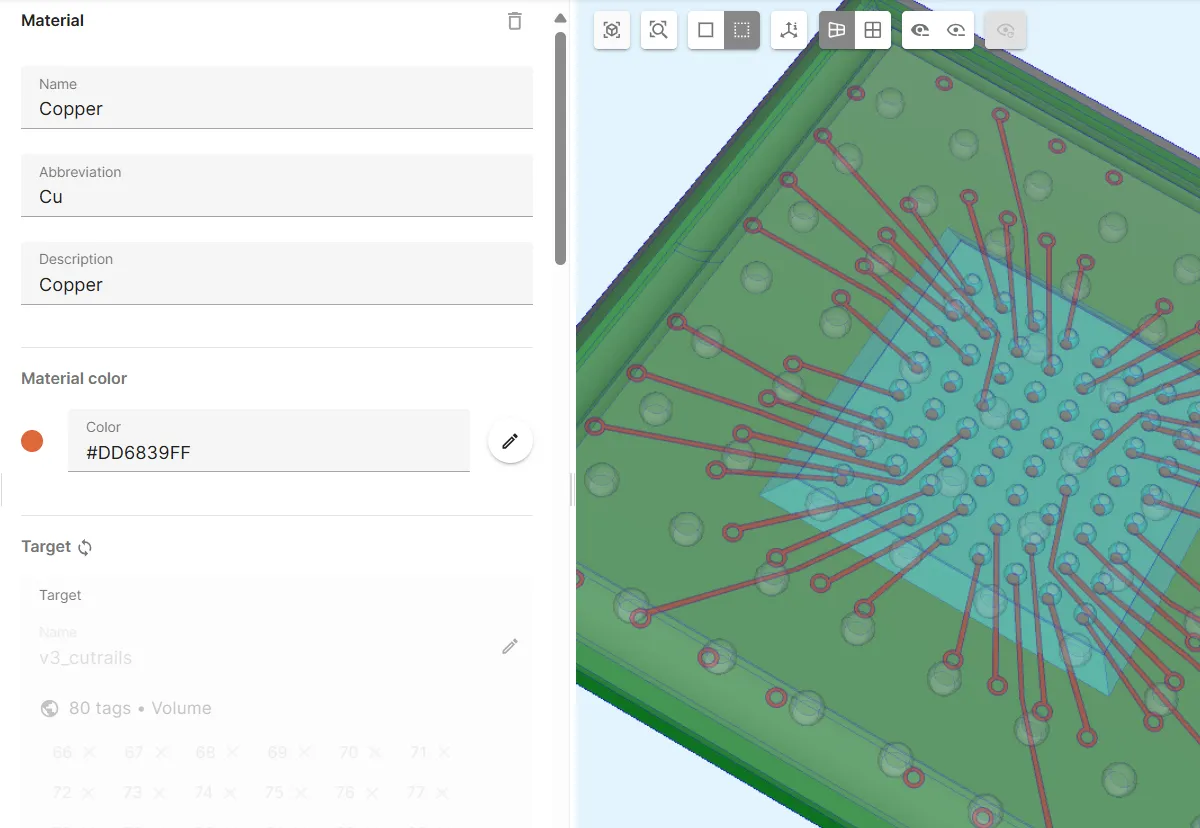

Material 5 - Copper

Section titled “Material 5 - Copper”The Copper material is assigned to the FCBGA cut rails.

- Pick

Copperfrom the materials library. - Select the

v3_cutrailsshared region as target.

Now, your Copper material is defined.

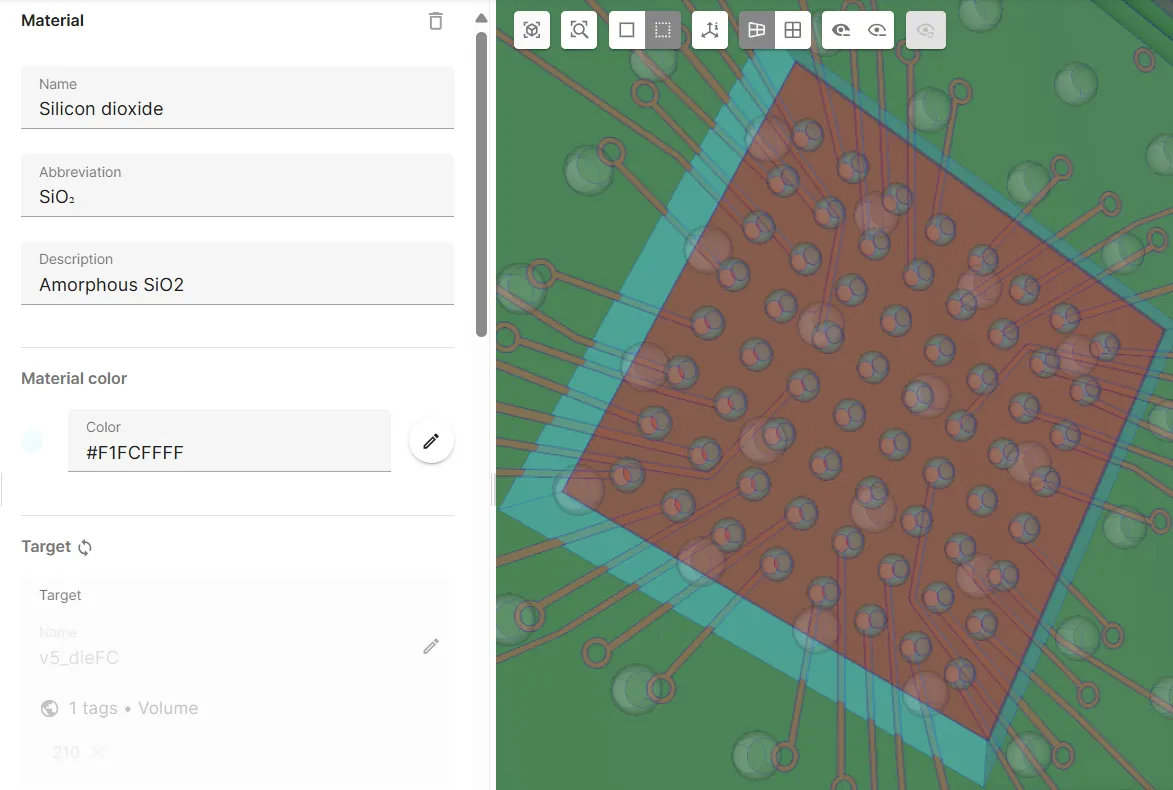

Material 6 - Silicon dioxide

Section titled “Material 6 - Silicon dioxide”The Silicon dioxide material is assigned to the FCBGA flip chip.

- Pick

Silicon dioxidefrom the materials library. - Select the

v5_dieFCshared region as target.

Now, all your model materials are defined.

Step 5 - Define the physics

Section titled “Step 5 - Define the physics”Proceed to the Physics section to define the project physics, interactions and couplings.

In this example, two physics are required:

See the corresponding subsections for detailed definitions.

Physics 1 - Solid mechanics

Section titled “Physics 1 - Solid mechanics”- Let the solid mechanics target default to the whole geometry.

- Add the Solid mechanics - Heat solid coupling

Thermal expansion.- As target, select the shared region

allreg, which contains all volumes in the model. - Set Reference temperature to

Tsf.

- As target, select the shared region

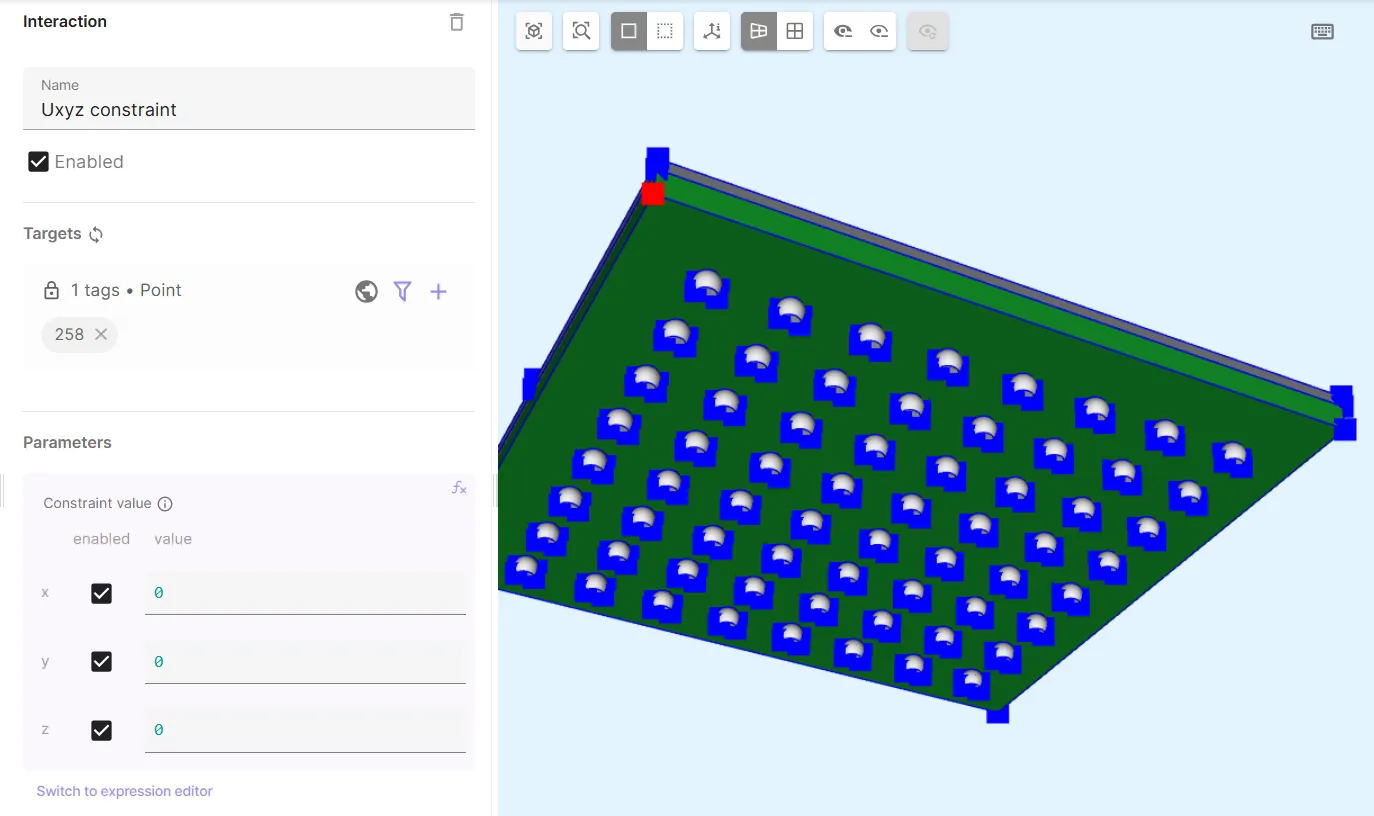

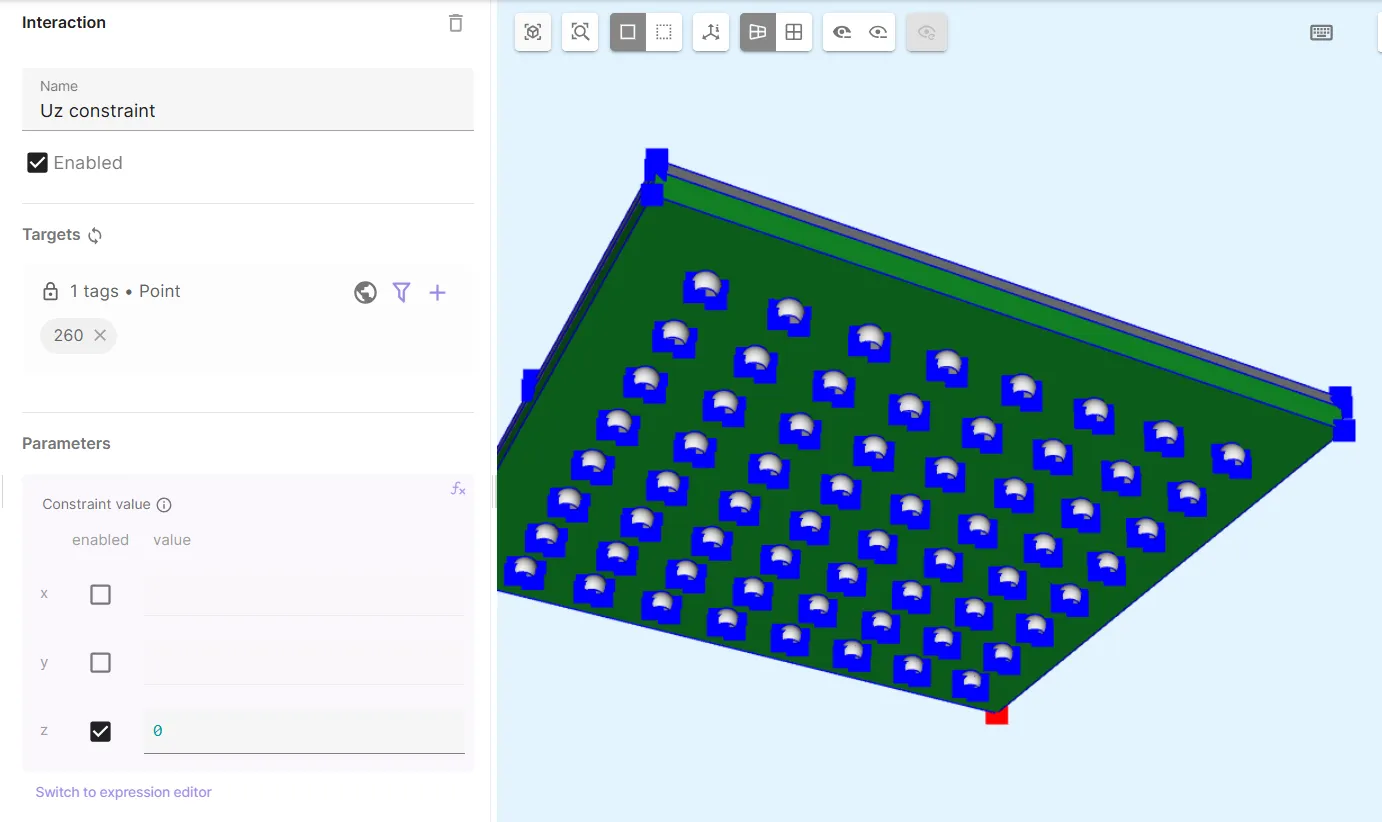

- Add Constraint and name it as

Uxyz constraint.- As target, choose a bottom corner point on the substrate volume

- Set Constraint value to

[1, 0; 1, 0; 1, 0].

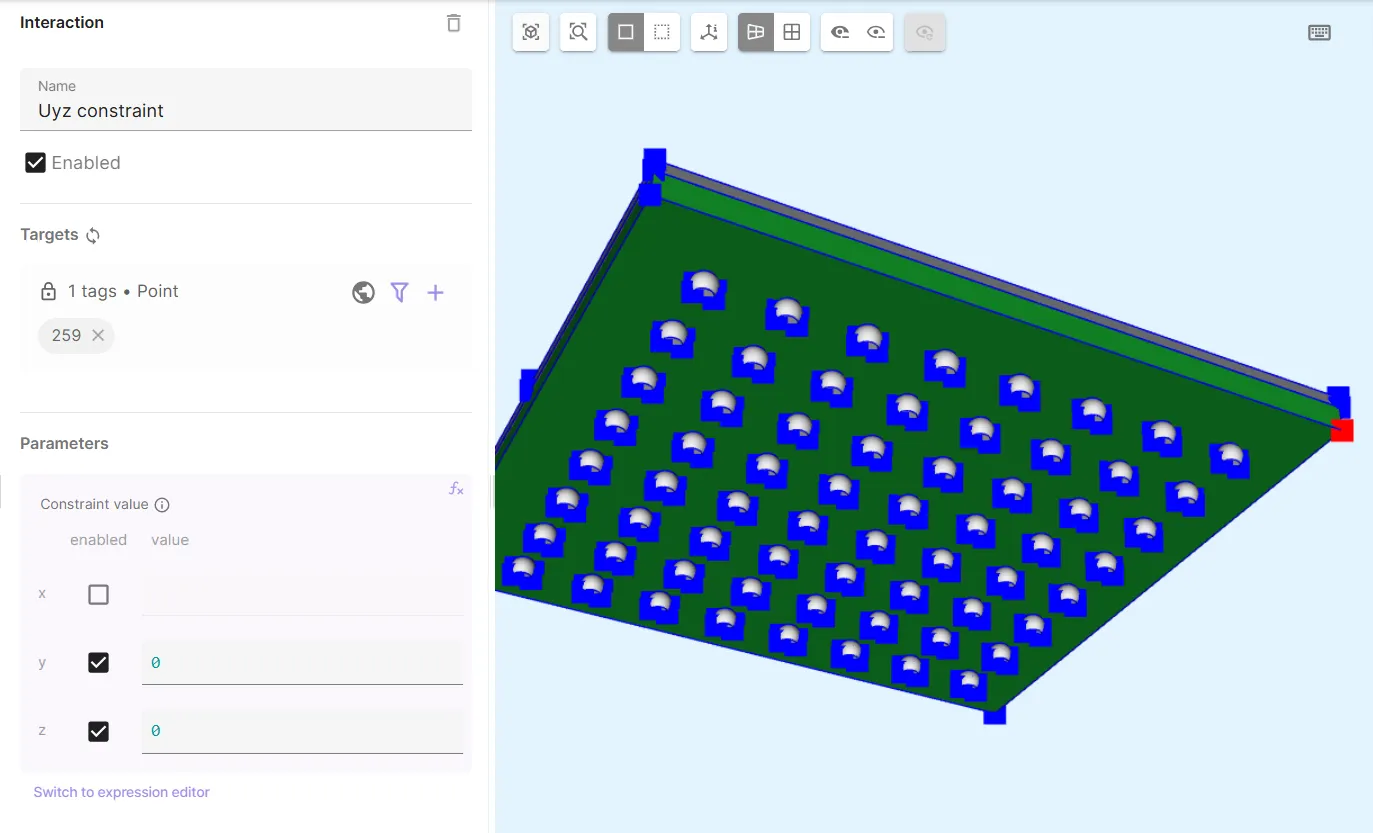

- Add another Constraint and name it as

Uyz constraint.- As target, choose another bottom corner point on the substrate volume

- Set Constraint value to

[0, 0; 1, 0; 1, 0].

- Add a third Constraint and name it as

Uz constraint.- As target, choose a third bottom corner point on the substrate volume

- Set Constraint value to

[0, 0; 0, 0; 1, 0].

Now, your solid mechanics are defined.

Physics 2 - Heat solid

Section titled “Physics 2 - Heat solid”- Let the heat solid target default to the whole geometry.

- Add

Constraint.- As Target, select the shared region

allreg, which contains all volumes in the model. - Set Constraint value to

Tend.

- As Target, select the shared region

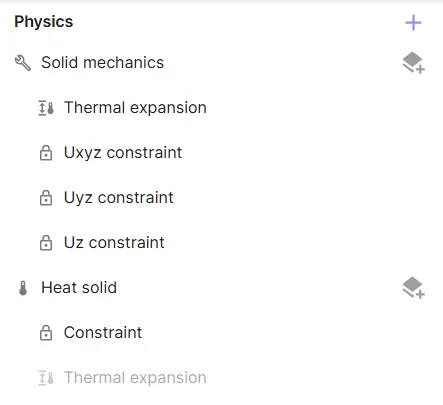

Now, all your physics, as well as their interactions and couplings are defined. Before moving on, check that your physics tree looks like in the image below.

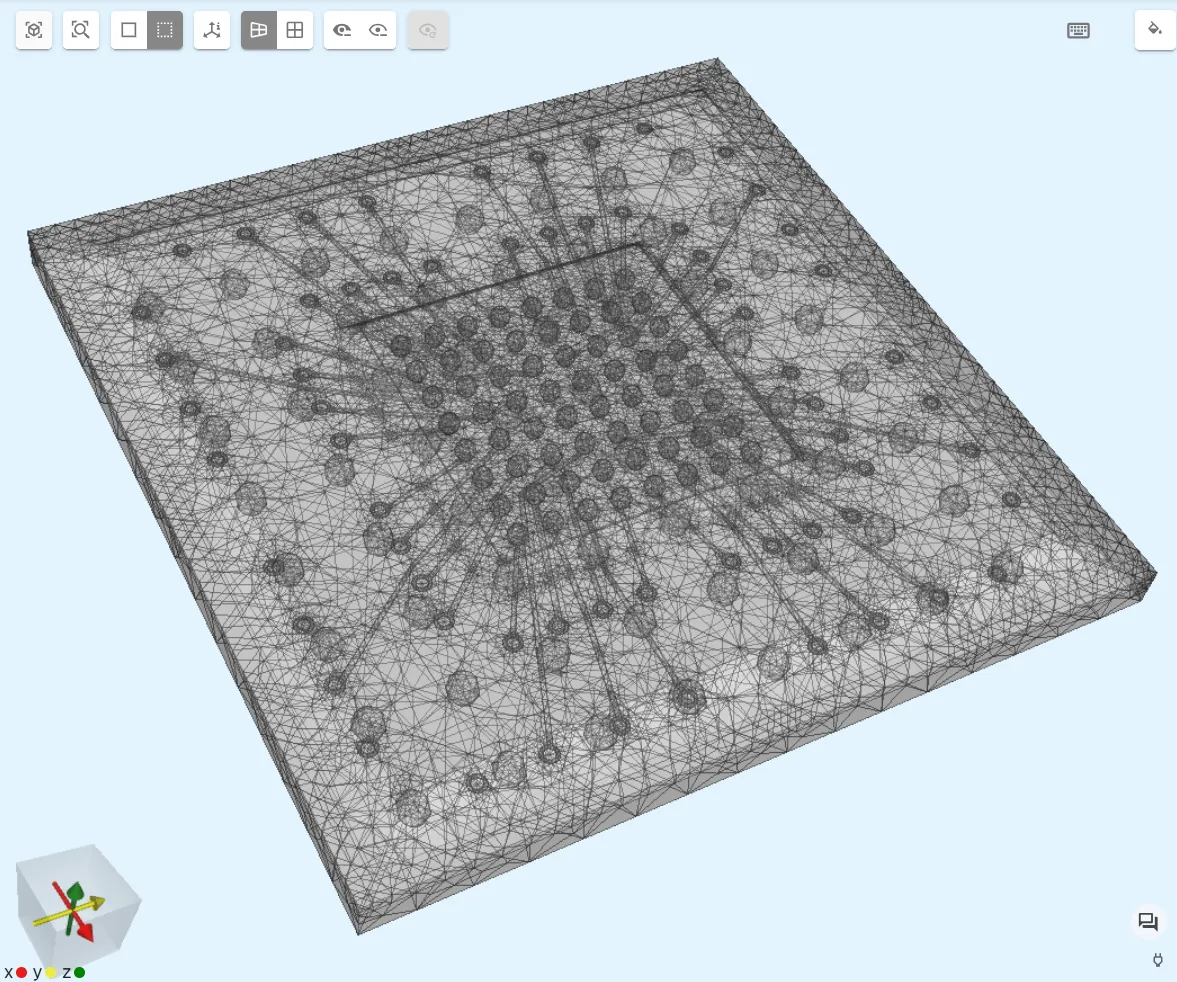

Step 6 - Generate the mesh

Section titled “Step 6 - Generate the mesh”Proceed to the Simulations section and create a new mesh:

- Set Mesh quality to

Expert settings. - Set Scale factor to

2. - Click

Apply and mesh. - Once meshing is finished, click

Show preview.

In the preview, your finished mesh should look something like in the image below.

Step 7 - Simulate

Section titled “Step 7 - Simulate”In the Simulations section, create a new simulation:

- In Simulation settings:

- Set Analysis type to

Static. - Set Node count to

10. - Set Node type to

1 CPU, 16 GB.

- Set Analysis type to

- In Mesh, select the mesh you generated in step 6.

- In Outputs:

- Add

ufield output.- Enable

skin only.

- Enable

- Add

Your simulation is ready to run.

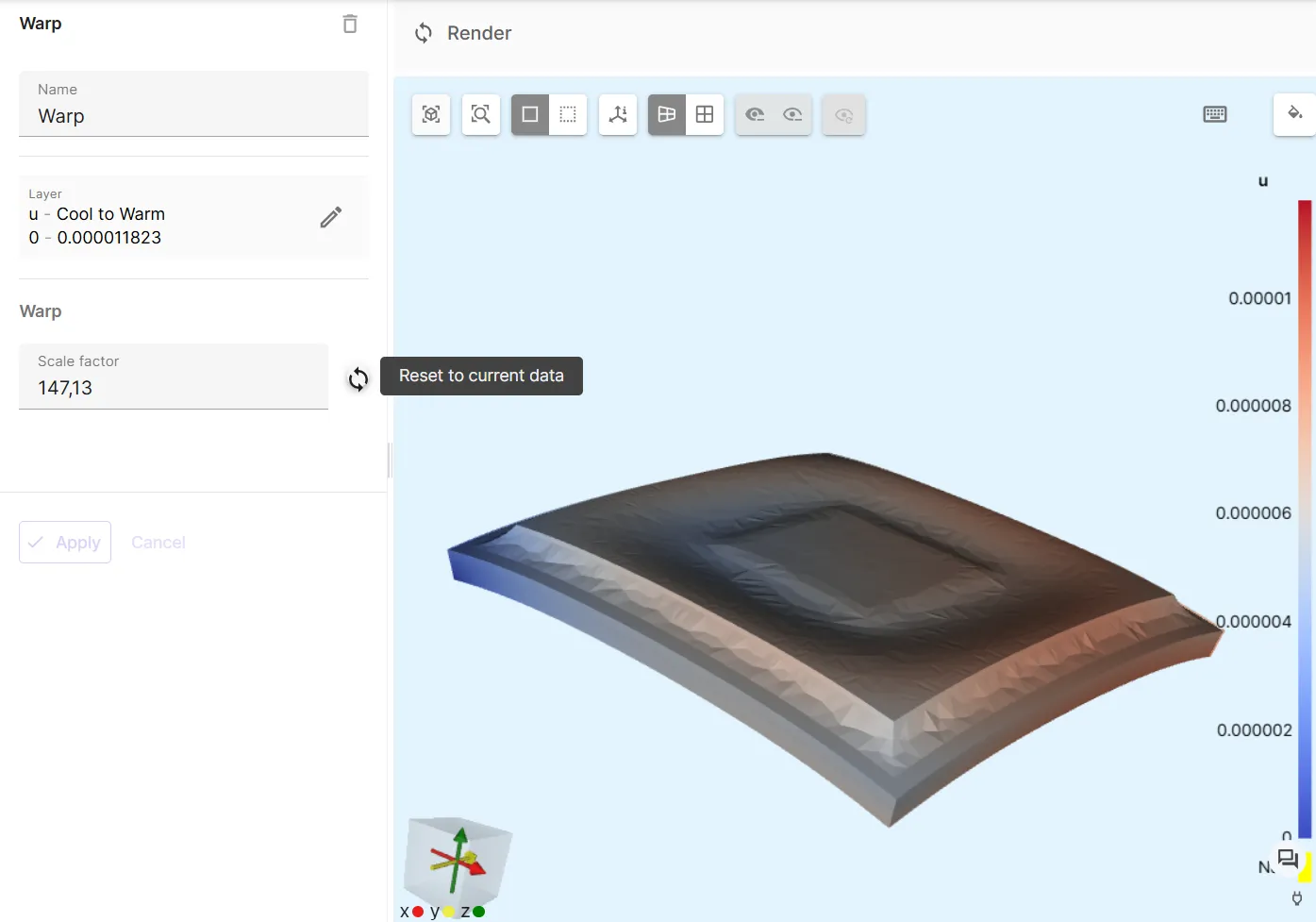

Step 8 - Plot & visualize

Section titled “Step 8 - Plot & visualize”In the Simulations section, add plots to see value output results, or visualizations to see field output results.

To visualize the u field output, for example, add a new visualization:

- Click

+next to Visualizations. - Click

+next to Visualization 1 and Select fieldu. - Click

+next to u and selectWarp. - Click

Reset to current datanext to Scale factor. - Click

Render.

Results

Section titled “Results”Below is an example of warpage results post-processed to an animation.